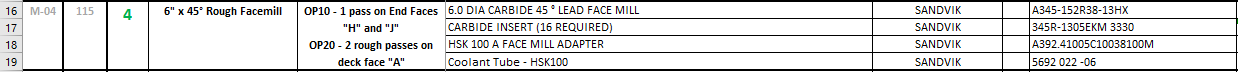

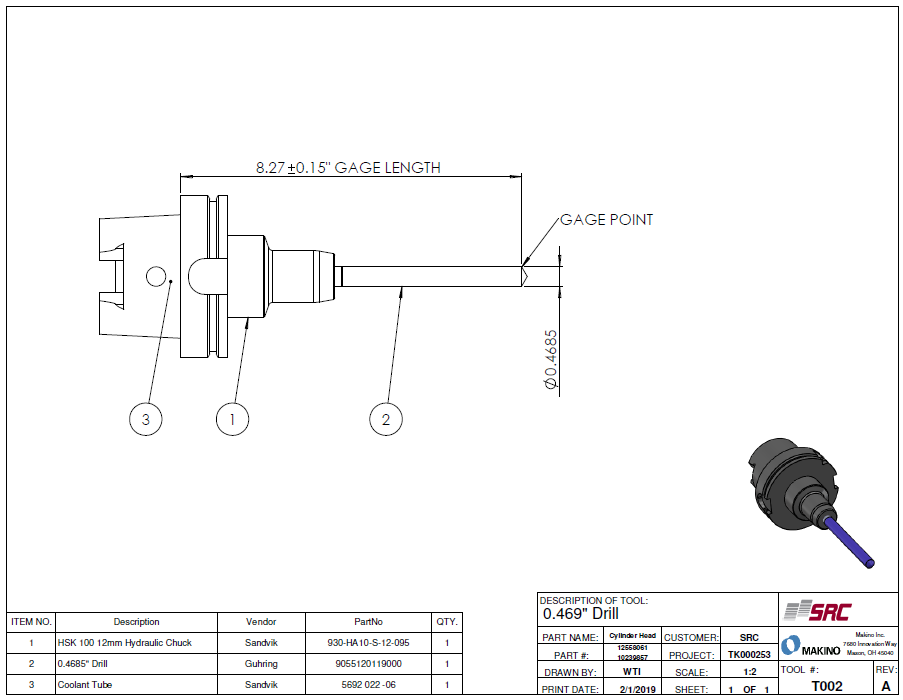

Folder Location and Information

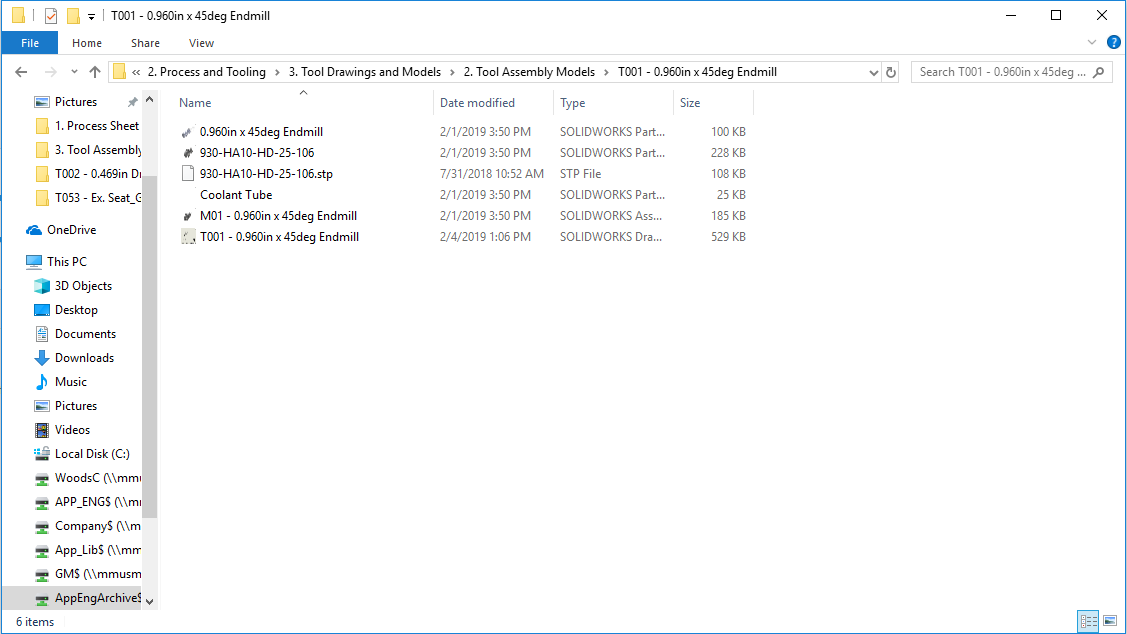

You will be making assemblies and drawings and need somewhere to put them. The best way to do this is to create a folder for each individual tool. The folders will include everything for each tool -- tooling components, tool assembly made from the components, and the drawing of the assembly.

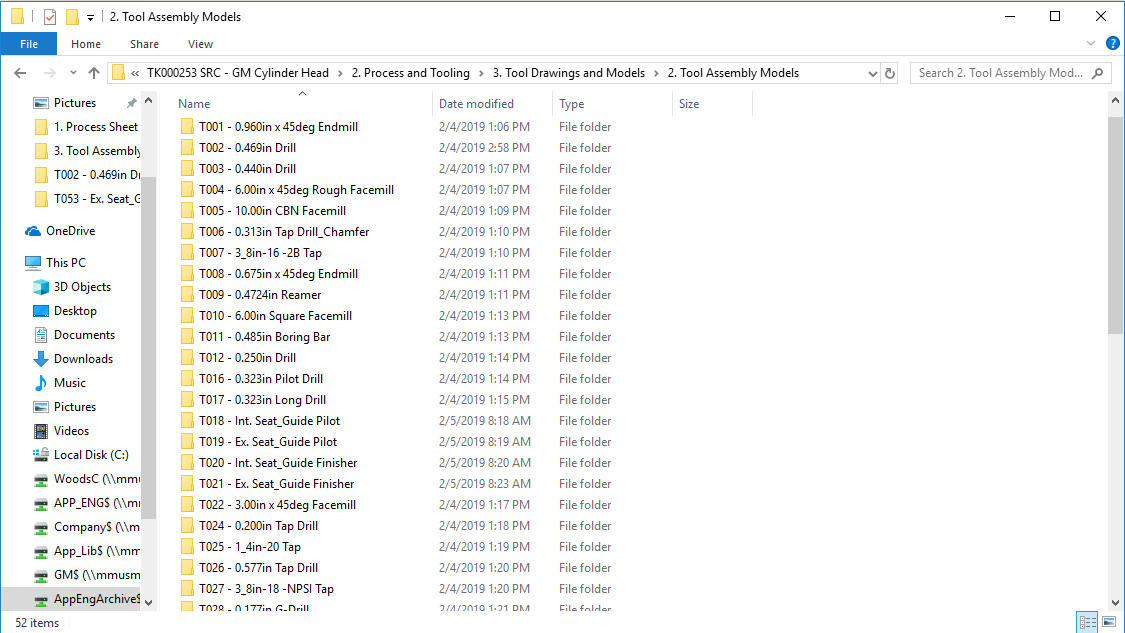

The tool folders should be created in S:Projects<YEAR><PROJECT NAME>2. Process and Tooling3. Tool Drawings and Models2. Tool Assembly Models

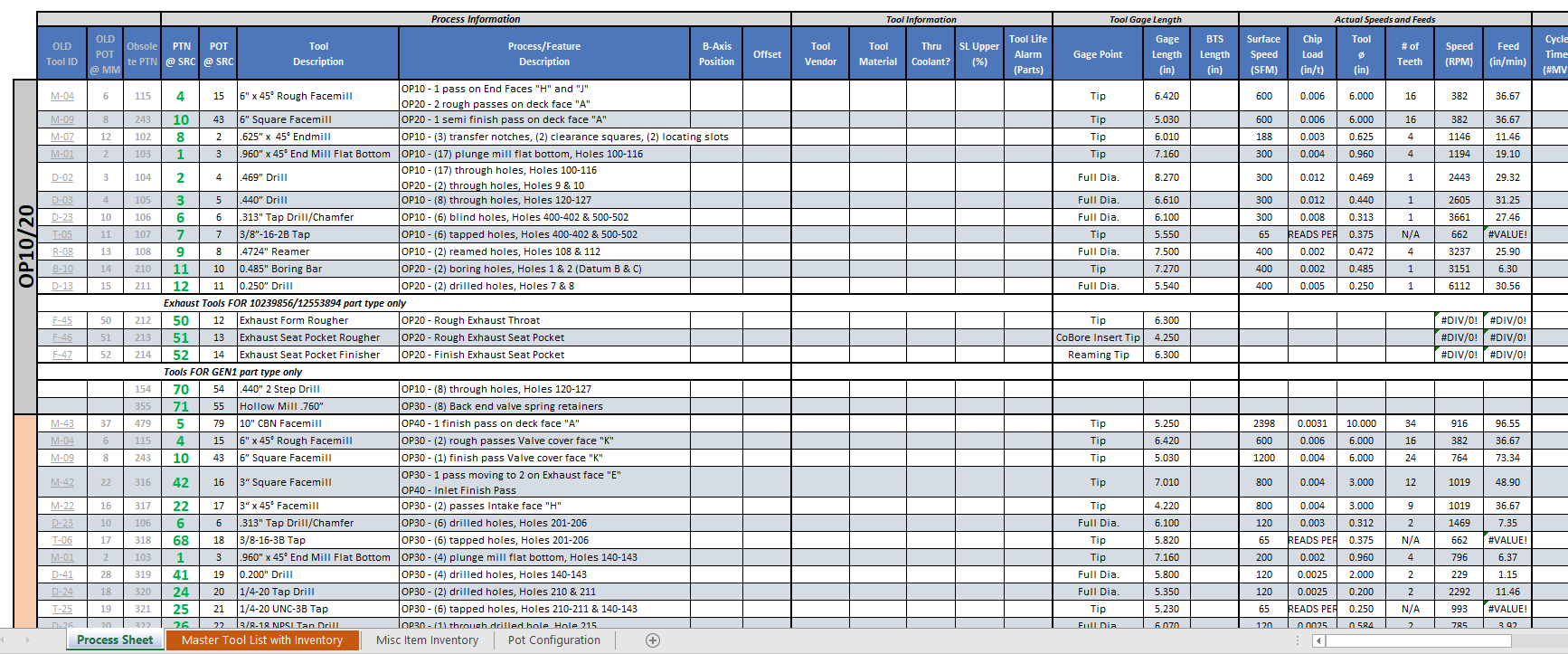

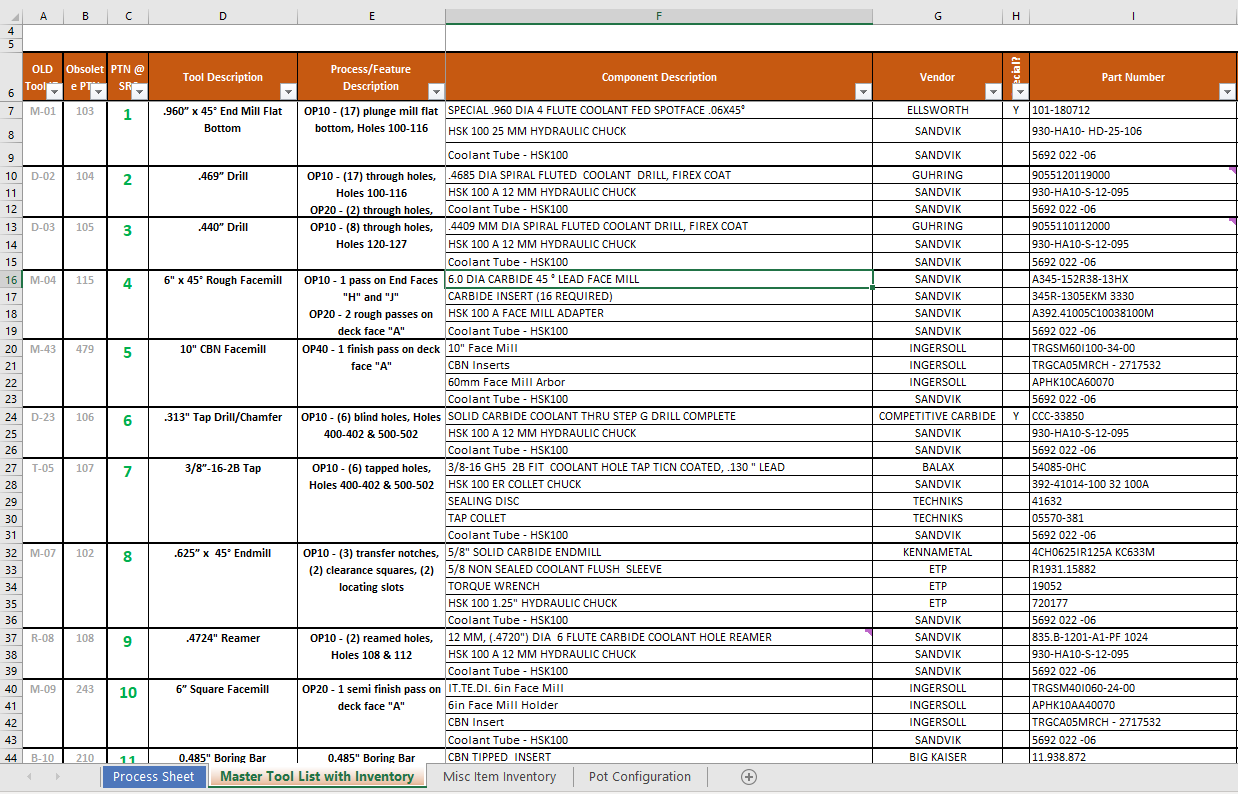

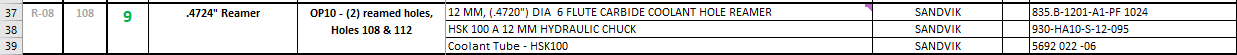

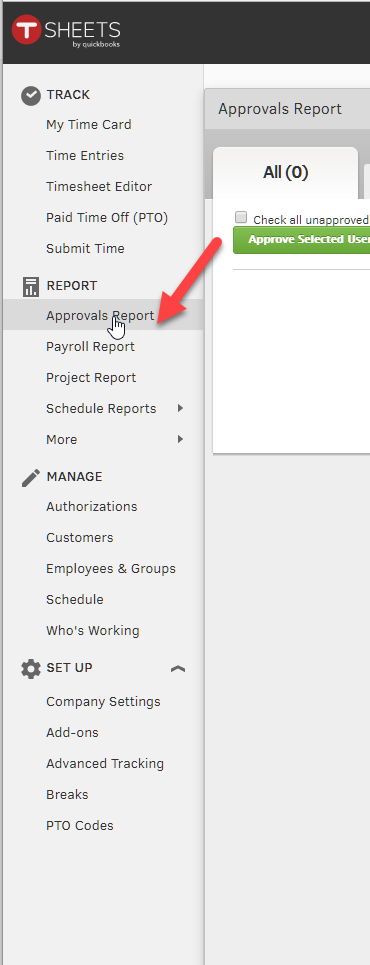

Folders should be labeled with tool number and description as shown in the first image below. That information can be found on the Process Sheet. It is located on S:Projects<YEAR><PROJECT NAME>2. Process and Tooling1. Process Sheet and Tool List