Process Mapping: How to Create a Blueprint for Business Success

Process mapping techniques are an essential tool for businesses looking to improve processes.

In a nutshell, they transform businesses from inefficient to streamlined. And best of all, they are not as complicated as they seem!

Process mapping can be thought of as a form of art because of its visual presentation approach.

And if you enjoy art as much as we do, you’d be happy to know that process documentation also plays a big part in it! Knowing where one task ends and another begins isn’t always clear.

That’s why understanding complex processes and figuring out how to document them clearly is very much an art as well as a science.

With that said, we’ve already written a guide to process mapping.

In this post, we’ll take a look at some more advanced process mapping techniques that will help you transform your business operations and streamline recurring work.

Intrigued? Then let’s dive in.

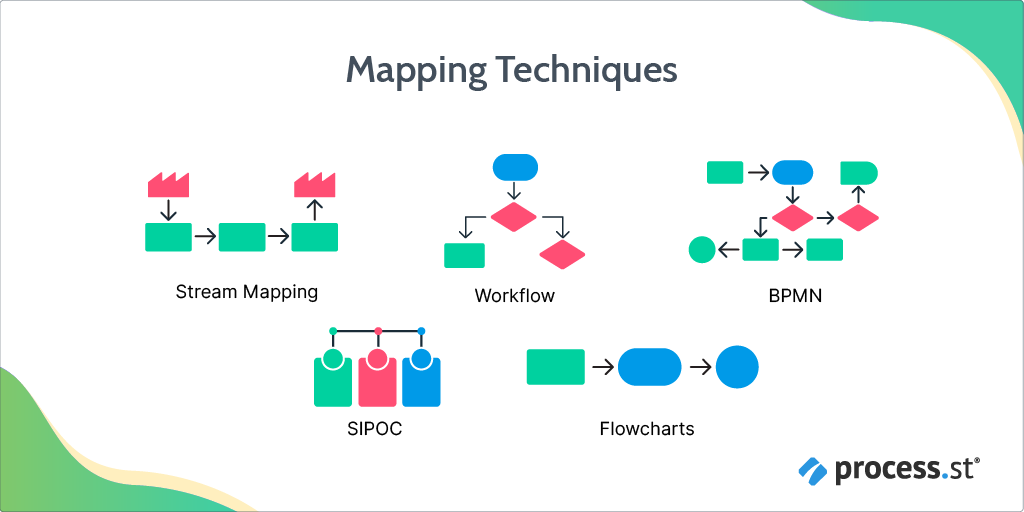

Process mapping techniques

We researched all of the best process mapping techniques and decided on the below list.

We made sure to consider reputability, tried-and-tested techniques that are proven to be effective, and cut through the noise so you don’t have to!

So let’s explore some of the most popular techniques.

Workflow process mapping

Workflows mapping can help you identify the steps in a process & break it down into a visual reference.

By creating a workflow diagram, you’ll be able to understand how the process flows from start to finish.

Visual workflow diagrams are used for mapping processes with visual symbols in a way that’s more free-form and distinct from more standardized flow charts.

You can also easily pinpoint areas where steps can be improved or eliminated. This technique is handy for complex processes involving multiple people or departments.

Flowcharts

One popular process mapping technique is flowcharting. Flowcharts use standardized symbols to represent each step in a process.

This makes it easy to understand the flow of a process and identify potential bottlenecks or areas for improvement.

Stream mapping

Another technique is value stream mapping, which focuses on the value-added steps in a process and helps to eliminate non-value-added steps.

You can use a process mapping technique in various industries and settings, including manufacturing, healthcare, and service.

Business Process Modeling Notation (BPMN)

This standardized notation provides a common language for describing business processes.

It uses a set of graphical symbols and rules to define the steps of a process and the relationships between them.

Thanks to BPMN, you’ll communicate more effectively and make more informed decisions about process improvements.

SIPOC diagrams

SIPOC (Suppliers, Inputs, Processes, Outputs, and Customers) diagrams identify the key elements of a process.

This technique is beneficial for cross-functional teams who may have different perspectives on the process.

Creating a SIPOC diagram ensures that everyone has a shared understanding of the process.

This section will help if you’re confused about which technique would best suit your situation.

Process maps vs. flowcharts

This section will help if you’re confused about which technique would best suit your situation.

We’ve chosen two of the most common process mapping techniques for you to explore – process maps and flowcharts.

Although these terms are sometimes used interchangeably, there are some key differences between the two.

So let’s clarify.

Process mapping

If you need a high-level overview of a process and to identify areas for improvement, process maps may be the ones for you.

There are different types of process maps, such as swimlane diagrams and value stream maps, and you can use various templates, such as lean process mapping templates.

Flowcharts

These are diagrams that use symbols and arrows to show the flow of a process.

So you may choose them to document detailed process steps and identify potential bottlenecks.

Flowcharts are commonly used in process improvement initiatives, such as Six Sigma.

Which one is better?

The answer to this question depends on your particular situation.

While process maps and flowcharts are practical process mapping techniques, they serve different purposes.

In lean process mapping, a combination of different process mapping techniques is often used to identify inefficiencies and improve processes.

For example, use a value stream map to identify non-value-added steps or a swimlane diagram to determine department handoffs.

Supplement process mapping with workflow documentation

Here we have yet another process mapping technique! Yes, it sounds like there’s a lot, but stay with me!

If I had to choose between techniques, workflow mapping would always be my first choice.

Let me show you why.

If your goal is to map your processes, the important thing you’re trying to do is understand the flow and order of work.

Drafting up a workflow diagram with pencil and paper, a whiteboard, or an online process flowchart tool is a great starting point – it might even be easier to get the essential info jotted down. When you’re done, you’ll have a clear roadmap from start to finish of the process.

So what’s next? Ideally, you’d take that blueprint and figure out how to make it more actionable.

Traditional process mapping or diagramming is great, but what people often don’t realize is that without actionability, process diagrams have very limited use.

So you need to figure out how to take your process maps to the next level – what you want to end up with is clearly defined, actionable steps. That’s where workflow management software can be useful.

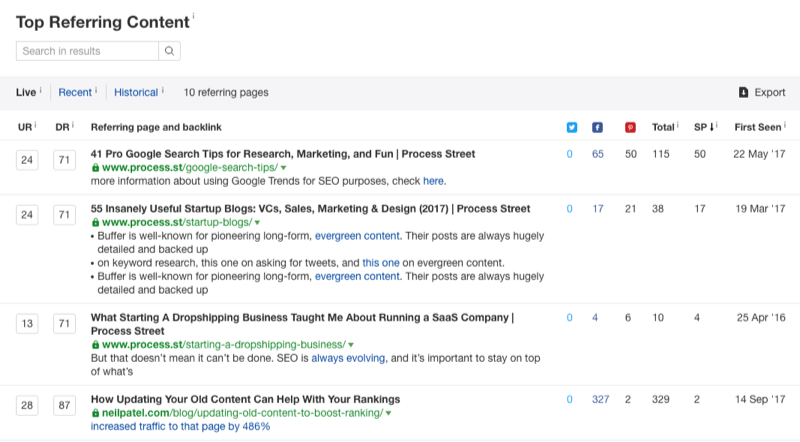

Process mapping tools

As promised, I’ve devised a list of the best process mapping tools to use right now!

But what are workflow process mapping tools? Essentially, they are software applications designed to help create and manage workflow diagrams.

These tools often include pre-built symbols and templates that make it easy to create professional-looking workflow diagrams.

Some of them, however, are designed to work with more visual process mapping tools to unlock actionability and more effective process ownership.

Workflow process mapping use symbols are icons that represent different components of a process, such as tasks, decision points, and inputs/outputs.

These symbols are standardized across workflow process mapping tools to ensure consistency and understanding.

Some common symbols include circles for events, rectangles for tasks, and diamonds for decision points.

These tools range from basic software programs like Excel to specialized software programs designed for process improvement initiatives.

Ready?

Let’s start with the most robust tools first:

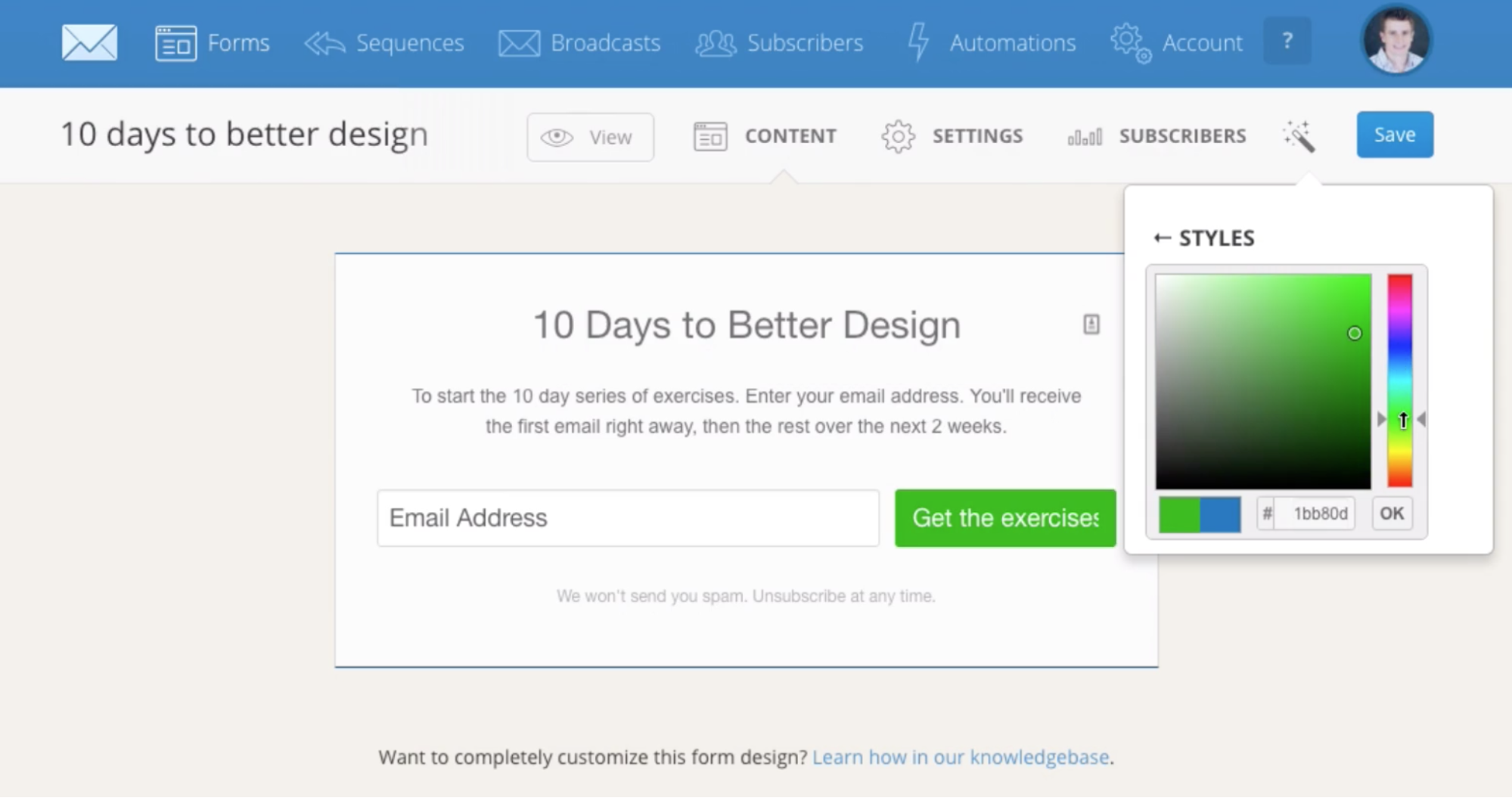

Process Street

This powerful process management and workflow-building tool will help you create, manage, and improve all processes.

Process Street works well as a supplemental process mapping tool that can help build on top of visual process diagrams.

The platform offers a variety of features, including process templates, checklists, and automation.

It allows you to create detailed process map plans from scratch, with step-by-step instructions and links to related documents and resources.

It also comes with features like:

- approval workflows

- reporting, and analytics

- intuitive AI workflow builder

- Pages

- Conditional logic

- 100’s of integrations with other software

One of the key benefits of Process Street is its ease of use, making it accessible to users with varying levels of technical proficiency.

Visio

Microsoft Visio is a powerful process mapping tool that lets you design detailed flowcharts and diagrams.

Google Drawings

A free, cloud-based tool that will make creating processes quick and easy.

Excel

While Excel may not offer the advanced features of other tools, it can still be valuable for creating simple process maps and analyzing data.

Use case: process mapping in healthcare

Now, let’s discuss a process mapping use case.

I’ve chosen healthcare because it’s one of the most complicated industries when it comes to processes.

Process mapping is a valuable tool in healthcare because it improves the quality of care and patient outcomes.

Healthcare processes often involve multiple departments, which makes it challenging to identify inefficiencies and areas for improvement.

By creating process maps, healthcare organizations can visualize their processes, identify bottlenecks, and streamline workflows.

Some examples of healthcare processes that can be improved with process mapping include:

- patient admission and discharge

- medication administration

- laboratory testing

Process mapping is suitable for healthcare organizations since it helps to reduce wait times, minimize errors, and improve patient satisfaction.

One of the disadvantages of process mapping in healthcare is that it can be time-consuming and resource-intensive, requiring significant investment in time and personnel.

However, process mapping in healthcare quality improvement projects can significantly lower costs.

And because process mapping can identify inefficiencies and streamline workflows, the result is improved patient outcomes and increased efficiency.

The Six Sigma method of process mapping

Six Sigma methodology focuses on decreasing defects and enhancing process quality through data-driven analysis and continuous progress.

Process mapping is a critical component of Six Sigma, providing a graphical model of processes that you can analyze for inefficiencies.

The most detailed type of process map used in Six Sigma is the “detailed process map,” which provides a comprehensive view of a process.

It includes inputs, outputs, controls, and process steps.

One of the unique process maps used in Six Sigma is the “5K map,” which stands for “keep, kill, combine, create, and change.”

This process map assists in recognizing which steps in a process are:

- Essential (“keep”)

- Unnecessary (“kill”)

And which:

- Can be merged with other steps (“combine”)

- Should be added (“create”)

- Need to be modified (“change”)

Process mapping has been used effectively in many industries to improve quality and reduce defects.

Let’s take healthcare as an example again.

A hospital might use Six Sigma process mapping to analyze the discharge process for patients and pinpoint bottlenecks that could be addressed to decrease the length of stay and improve patient outcomes.

How to create a process map

Workflow process mapping is like a roadmap to visualize and understand the flow of a process.

So it’s perfect for whenever you’re dealing with complex processes where multiple people are

involved.

You can incorporate workflow mapping pretty much

in any department:

- project management

- software development

- business process improvement

- customer service

- and many more!

Best of all. This technique is extremely versatile!

You can manually do workflow process mapping using paper, a whiteboard, or workflow process mapping tools.

Now that we know more about process mapping, let’s see how to create one.

Define the process

Begin by identifying the process you want to map.

Define the boundaries, such as the start and end points of the process, and determine the inputs and outputs.

This information confirms that you understand the process and can create a comprehensive process map.

Gather information

Collect data from employees, customers, and other stakeholders involved in the process.

You can use various methods, such as interviews, surveys, and observation.

Choose a process mapping tool

There are various tools that you can use to create a process map.

I’ve already provided you with some of the best ones in “process mapping tools,” so review that section again if necessary.

Choose the tool that best fits your needs and is most comfortable for you to use.

Create the map

Now, you can start outlining the process steps on the map.

Use shapes and symbols to depict process elements, such as rectangles for tasks and diamonds for decision points.

Utilize arrows to indicate the flow of the process, and label each shape with a brief description of the task.

Include important information like timing, resources needed, or specific instructions.

Review and revise

Once you have created the process map, review it with employees and customers.

Make sure that the map accurately represents the process and is easy to understand. Incorporate feedback and revise the map as needed.

Process mapping will lead to efficiency and quality improvement

When done correctly, process mapping allows for clear visualization of the steps involved in a process and identifies inefficiencies and improvement areas.

There are various process mapping techniques and tools available, so it’s wise to first assess your business needs before committing to one.

If you want to take your process mapping techniques to the next level, focus on making them actionable by documenting tasks at each node/point of the map

Just know that process mapping will streamline processes and improve efficiency significantly. This is because it will help you identify inefficiencies and develop solutions to eliminate them.

Workflows

Workflows Forms

Forms Data Sets

Data Sets Pages

Pages Process AI

Process AI Automations

Automations Analytics

Analytics Apps

Apps Integrations

Integrations

Property management

Property management

Human resources

Human resources

Customer management

Customer management

Information technology

Information technology