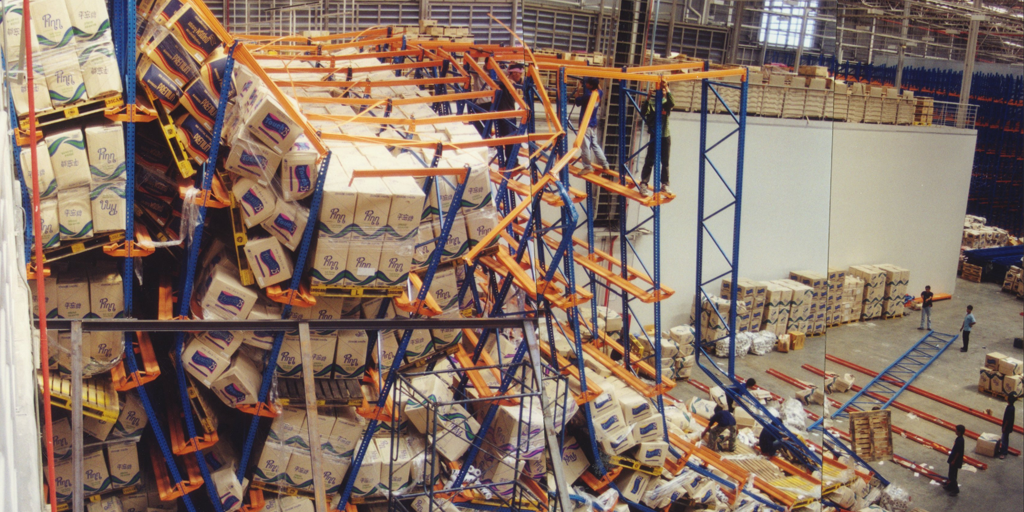

Having a warehouse safety checklist to run every month might seem like a pain, but it beats paying $82.5 million in a lawsuit following from flouting safety regulations.

Instead, just use this checklist to check that everything in your warehouse is up to standard and that your employees are safe and sound.

From surface damage to obstructions, it's time to eliminate every hazard in your facility.