You can’t earn €38.8 billion in annual revenue by stumbling through your processes.

Specifically, the IKEA supply chain is the glue that holds the company together and allows them to flourish.

From their suppliers through to the product in-store, the supply chain is set up and managed in a way that reduces costs at every stage, makes the products more appealing to customers, and makes the brand as a whole seem more appealing.

It’s genius, really.

So let me show you how they do it.

The IKEA supply chain starts with a vision

At its core, IKEA has a vision.

‘“To create a better everyday life for the many people”, this is the IKEA vision. Our business idea is “to offer a wide range of well-designed, functional home furnishing products at prices so low that as many people as possible will be able to afford them”‘ – IKEA on their Vision and Business Idea page

This means that IKEA aims to improve the lives of everyone involved in their supply chain as well as their customers while keeping prices low through things like clever product design.

Here’s the thing. It works because they stick to it.

It’s not difficult to make a working supply chain or deploy a business system in general. It is difficult to create a coherent one where everything is done to work towards a single goal.

Through every stage of the IKEA supply chain it’s obvious that the vision has been considered, applied, and upheld. This means two things:

- IKEA is able to present a consistent front to suppliers and customers alike

- There is a specific goal to consider when implementing changes and optimizing the chain

This makes managing the supply chain easier when it comes to key decisions and provides the benefits associated with their particular goals.

Namely, this vision means that IKEA:

- Reduces waste

- Has decent working conditions at all supply chain levels

- Is able to accurately predict output

- Creates long-lasting relationships (which drives down costs and improve reliability)

- Can minimize floating inventory

- Is environmentally conscious throughout the supply chain

- Provides low prices due to everything working together

To show how much efforts goes into achieving even one of these benefits, let’s take a look at how IKEA’s supply chain and vision influence their ability to waste.

Reducing waste across the supply chain

I know this is an obvious point but reducing waste of all kinds boosts profits and drives down costs.

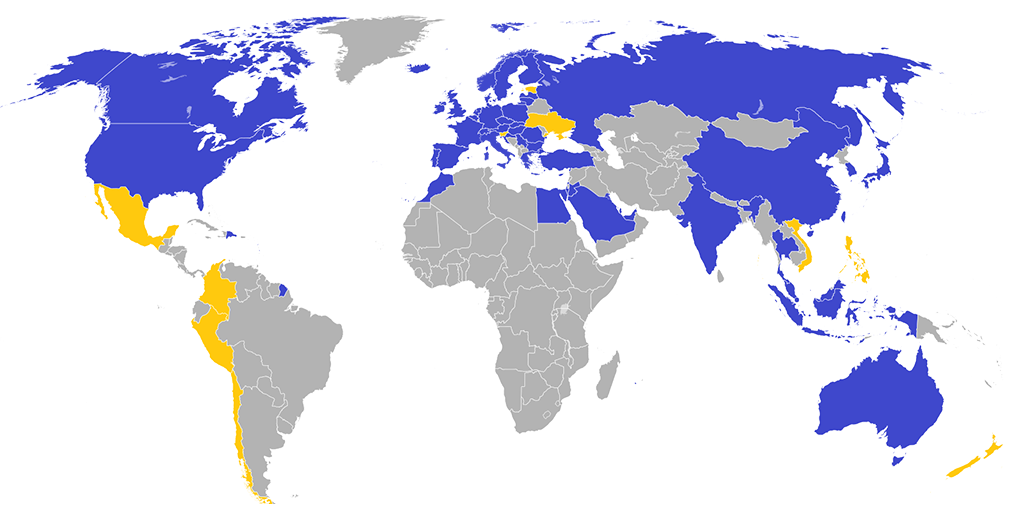

This, along with their reach with 403 stores across 49 countries, is a core factor to how they sustain over $38 billion in profit.

It’s also how the IKEA supply chain stands apart from many competitors, as the waste reduction isn’t driven purely by a desire for profit – it’s a core part of their values, and so is intrinsic to any important business decisions.

IKEA doesn’t think of waste as a singular item; they realized that it’s a combination of several key factors.

- Material choice

- Material sourcing

- Product design

- Transportation

- Product storage

- Inventory management

Savings can be made in any given category (eg, reducing inventory waste by limiting the number of on-site items) but the benefits (and difficulty) of pursuing all categories is staggering to say the least.

Again, IKEA solves this issue by centering around their vision statement.

Products are designed to be as ergonomic as possible and use materials that can be created from sustainable sources. IKEA prioritizes long-term relationships with their suppliers to lower costs rather than rely on the lowest bidder (at the expense of business practices).

Combine this with their efficient approach to inventory restocking (which limits inventory to a small surplus and factors expected demand into order size), and IKEA manages to create a supply chain which is both efficient in a business sense and marketable to their customers.

After all, it’s highly marketable to have products that are both environmentally friendly and worker-conscious.

IWAY and the “e-wheel”

Special tools and guidelines have also been developed to help IKEA’s supply chain reduce waste across all fronts while sticking to their original vision. These are namely the IWAY guidelines and the “e-wheel”.

IWAY

The “IWAY” (The IKEA Way on Purchasing Products, Materials and Services) is a set of guidelines which IKEA presents to suppliers in order to set out in writing what it expects of them and what it will provide in return.

This serves several vital purposes:

- It helps IKEA to make sure that their products are sourced more sustainably

- Suppliers know what standards they’re expected to meet before signing up with the company

- Waste is reduced

- IKEA and suppliers alike know and can rely on the arrangement to be a consistent one

The IWAY also goes a long way in helping in aspects of the supply chain that IKEA doesn’t have direct control of. Namely, the business practices of their suppliers.

Not only would it go against their vision, it’s bad business to source products from suppliers that employ unsustainable production methods, bad working policies and/or pay, and even illegal practices such as child labor. Any of which is a PR scandal waiting to damage the brand.

That’s why IWAY is one of the most crucial factors in the IKEA supply chain. While it would be immensely difficult to personally make sure that every potential supplier is 100% sustainable, competitively priced, and good to their workforce, there’s a lot to be said for striving towards it.

Plus it provides an easy measure for which IKEA can use to see if a supplier is up to their standards and upholds their values. It turns the supply in the supply chain into something which aligns with the company while also reducing waste and maintaining their standards.

The “e-wheel”

The “e-wheel” is another tool IKEA developed to help them enforce their vision throughout the supply chain. While IWAY deals with suppliers, the e-wheel is focused on analyzing the environmental impact of each of their products.

To do this, each product is analyzed at five key stages:

- Raw material

- Manufacturing

- Distribution

- Use

- End-of-life

There’s less to say here than about the IWAY guidelines (at least in terms of how it’s applied). In execution it’s more involved as IKEA actively analyzes aspects such as how much of the product is made from sustainable or recycled sources, but for the purposes of looking at IKEA’s supply chain the effects at each stage are the same.

This means that each product for IKEA aligns with their goal of being more environmentally friendly which, as mentioned above, is appealing to customers. People feel better knowing that whatever they’re buying comes from a sustainable source.

IKEA’s take on inventory management

IKEA’s inventory management techniques also play a huge part in making their supply chain so reliable and successful. Several techniques are combined with a focus on decreasing the cost-per-touch of each item (more on that below), resulting in lower costs, optimized systems, and even a better ability to predict what order sizes need to be when restocking.

High-flow and low-flow products

Anyone who’s been to IKEA is familiar with their layout; a large main showroom where customers browse for the products they want, with a warehouse below from which people collect their product directly from the pallets.

This system couldn’t possibly work without a solid inventory management method to back it up. If someone can’t find a product (or it’s out of stock), they lose the sale.

“IKEA relies on everything being in the right place at the right time so customers can get to them.” – Jay Schofield, How IKEA Keeps Track of Their Massive Inventory

IKEA’s solution is to split up their product and facilities into two categories – high-flow and low-flow.

The 20% of products which make up 80% of a store’s sale volume are classed as high-flow. These are managed, monitored, and restocked using automated processes and storage, to reduce costs and increase the accuracy with which they’re tracked.

Automating processes also has the handy benefit of reducing the amount of shipping and manual restocking, thus reducing costs involved with 80% of each store’s sale volume.

All other products are classified as being low-flow, and are managed using manual processes (eg, employees manually restock everything) but with a reduced frequency compared to anything high-flow. This way the cost difference between using employees and automated machines is minimized as less is effectively spent on preparing each product.

In other words, IKEA uses this system to identify where it would benefit the most from automation and where it isn’t required due to slower sales naturally keeping costs low.

Maximum and minimum settings dictate order sizes

IKEA needs to have the products its customers want to buy. It also wants to avoid wasting money by bulk-ordering an item which then doesn’t sell, causing an excess amount of floating inventory.

To get the best of both worlds and keep organized, they use a system of “minimum settings” and “maximum settings” for every product. Both vary depending on how popular the product is, and can be adjusted to account for rising and falling sales.

The “minimum setting” is the smallest number of products which must be available before a new order has to be put in. For example, a popular product will need ordering well in advance of it going out of stock (giving it a high minimum setting), whereas a slower-seller won’t need as much stock to last the store between deliveries.

“Maximum setting” is the highest amount of each product which can be ordered at once. This avoids overstocking inventory or holding onto items and increasing costs when it isn’t necessary.

Combined, you have an efficient system for reducing waste, notifying you when a product needs restocking, and telling you how much you need to order to avoid increasing costs while meeting demand.

It’s simple in concept (like much of IKEA’s supply chain) but carefully considered and implemented to avoid the complications that come with real-world usage.

From IWAY to cost-per-touch: it’s all great business

Most of the IKEA supply chain is analyzed through waste reduction.

On the supplier end this results in assessing the environmental status of their products, the well-being of their workers, and the cost of their services. On IKEA’s end, the focus is more on efficient inventory management, increasing productivity and the cost-per-touch of each product.

“Every time a product is touched, shipped, moved, loaded, or shifted, it costs the company money, even if that’s as simple as an employee moving the product from one rack to another.” – Jay Schofield, How IKEA Keeps Track of Their Massive Inventory

Combined, these focuses let IKEA implement a supply chain which is successful on pretty much every front. It ensures:

- Products are stocked efficiently and on time

- Costs are greatly reduced

- Competitive product prices are possible

- Bad business practices (and thus PR) are reduced

- Suppliers are reliable due to long-term relationships

The best part?

It all began with a simple vision being broken down and used to shape the processes and systems they used.

If you want to learn more, check out the resources below:

- 17 Ecommerce Processes to Set Up, Maintain and Promote a Successful Store

- 8 Logistics Management Processes to Perfect Your Supply Chain

- Inventory Management Process Checklist

- 6 Retail Process Checklists to Keep Your Store Running Smoothly

Do you have any interesting supply chain stories to share? Let me know in the comments below!

Workflows

Workflows Projects

Projects Data Sets

Data Sets Forms

Forms Pages

Pages Automations

Automations Analytics

Analytics Apps

Apps Integrations

Integrations

Property management

Property management

Human resources

Human resources

Customer management

Customer management

Information technology

Information technology

Ben Mulholland

Ben Mulholland is an Editor at Process Street, and winds down with a casual article or two on Mulholland Writing. Find him on Twitter here.