We all like to know about the broader philosophies behind process improvements, but sometimes we need to knuckle down and look at some of the more technical details.

We all like to know about the broader philosophies behind process improvements, but sometimes we need to knuckle down and look at some of the more technical details.

One of the core techniques behind any process improvement, particularly in Six Sigma, is DMAIC.

This handy approach, pronounced duh-may-ik, is the key to employing Six Sigma and beginning your journey to being a process hero. We’re going to cover each step in the process and detail how to effectively enact every section.

This guide will lead you through from start to finish and get you ready to start employing lean Six Sigma within your business!

What is DMAIC?

DMAIC stands for:

- Define

- Measure

- Analyze

- Improve

- Control

DMAIC is a data driven improvement cycle designed to be applied to business processes to find flaws or inefficiencies – particularly resulting in output defects – and to combat them. The goal of employing DMAIC is to improve, optimize, or stabilize existing processes.

The development of the DMAIC methodology is credited to Motorola, but is largely a further expansion of systems developed by Toyota. You can read more about how Toyota has employed their process improvement techniques in our article How Toyota Saved Children’s Lives with Process Implementation.

What we’re going to do is look at each stage of the process and consider what needs to be explored and what kinds of tools and methodologies you might use throughout.

Before you dive in, consider reading this DMAIC Case Study to give yourself an overview of the process from start to finish with handy graphs. This case study should help you be able to visualize each step we undertake throughout the article within a broader context.

When do we use DMAIC?

Some organizations add an extra step to DMAIC at the beginning called Recognize where they evaluate whether DMAIC is the correct tool to use for their needs.

Some organizations add an extra step to DMAIC at the beginning called Recognize where they evaluate whether DMAIC is the correct tool to use for their needs.

Though we’re not formally recognizing that step within this article, it would be remiss to not appreciate the importance of this addition.

DMAIC cannot be used in all situations. It pertains to specific opportunities for process improvement.

So what are these specific conditions?

There are three main things worth considering when assessing a situation for whether DMAIC would fit:

- There is an obvious problem of some form with an existing process or set of processes.

- The potential is there to reduce variables like lead times or defects while improving variables like cost savings or productivity.

- The situation is quantifiable; the process itself involves measurable data and the results can be appropriately understood through quantifiable means.

Once you’ve recognized whether or not your process is a good fit for DMAIC, you can get started!

Define: Map the project and understand your aims

The Define stage is essentially the planning part of the exercise.

It consists of 7 key sections:

Define Customers and Requirements

How you carry out this stage depends on who your customers are. There are two subsections of customers, either internal customers or external customers.

Internal customers are levels of management within your organization or other departments who are reliant on the output of the particular process you are attempting to improve.

External customers would be the end users of your product or services. These would normally be your business clients but could also be the company’s shareholders.

We tend to divide the expectations of these customers into two related categories: needs and requirements. Needs refer to the end goals of a product: someone buys an air-conditioning unit because they want to keep a room cold. Requirements refer to features or aspects of a product: an air-conditioning unit needs to have a thermostat of some description in order to deliver the cold room the customer needs.

When judging the output of a process, we analyze who the customers are, what their needs are, and what the requirements are to fulfill these needs.

Develop Problem Statement, Goals and Benefits

The next step is to bring that customer information into actionable steps.

We want to develop a clear Problem Statement in order to communicate the purpose of the process and to help us understand how our actions will relate directly to the end results. This should not look to define the solution, but instead focus on the following aspects:

- What is the pain point?

- Where is it hurting?

- When has it been hurting? Is it long term or short?

- What is the extent of the pain?

The Six Sigma Institute provide the following example problem statement:

“In the last 3 months (when), 12% of our customers are late, by over 45 days in paying their bills (what) . This represents 20% (magnitude) of our outstanding receivables & negatively affects our operating cash flow (consequence) .”

In doing so, we should clearly define what our ultimate goals will be from the process improvement work we undertake. This might be identifying something simple like a need to increase output per hour from 100 units to 200 units. Or it might be improving clearly measurable rates of customer satisfaction or other similar quantifiable variables. In a pure Six Sigma approach, your goal would be to improve your Sigma baseline and reduce whatever your defined defects are – but we’ll come to all that later.

The goal statement should be SMART: Specific, Measurable, Attainable, Relevant and Time Bound.

The Six Sigma Institute example:

To reduce the percentage of late payments to 15% in next 3 months, and give tangible savings of 500K USD/ year.

Identify Champion, Process Owner and Team

(Source)

In order for us to implement this process improvement, we need to determine the roles of different employees in bringing the project to completion. Different companies will put differing emphasis on roles, so take the following as an example as much as a definition.

If you’re familiar with lean methodologies like Scrum, this will quickly make sense to you.

The Process Owner is the person who is responsible for the process improvement project. This is the hands on position where the person involves themselves with each team involved in the process, analyzes and tracks data and output, and looks to manage the process from above from the first step to the last. The Process Owner’s primary function is to provide the planning and overview to allow everyone else to flourish.

The Process Champion is an individual within the organization who has the power to make key decisions and facilitate the work of the Process Owner. This would likely be an executive who can help allocate resources to serve the needs of the Process Owner. The Champion aims to remove barriers which the Process Owner is facing and help facilitate the process improvement project from another step above.

The team in this context are the employees who will be putting the desired changes into action and helping monitor the effects of these changes. The main person in this team is the Black Belt; the project manager for the team. The other employees who focus on the Six Sigma process might be referred to as Green Belts (at this point it starts to feel a little like a karate kid cosplay).

Define Resources

In order to undertake this process improvement project, we need to know what resources are available for the Process Owner to utilize.

This might include a budget for contracting external services, purchasing additional tools, or travel expenditures. It might also refer to how many staff will be needed in order to make this change effectively; do staff need to be brought in from other departments, or will new staff need to be hired?

The amount of resources required will be defined by the problem and goal statements. You don’t want to spend $1 million to save the company half a million. We need to understand what resources are needed to tackle the project and what resources are reasonably available.

Evaluate Key Organizational Support

Now you know what resources you need to begin the project, you need to know what support you can gather from other actors within your organization.

The Process Champion will be in charge of attempting to mobilize this support from other areas of the company. In order to do this, the Process Champion will likely try to create a Business Case.

The purpose of a Business Case is to demonstrate the importance of this process to the broader operations of the company. The Six Sigma Institute give us an example of 7 questions which a Business Case should answer:

- Why is the project worth doing? Justify the resources necessary to engage in the project.

- Why is it important to customers?

- Why is it important to the business?

- Why is it important to employees?

- Why is it important to do it now?

- What are the consequences of not doing the project now?

- How does it fit with the operational initiatives and targets?

The Institute also provides us with an example Business Case:

By reducing the average transaction length, the queue would be able to enhance the Speed of Resolution and assist the end-users in fastest possible manner. This will not only help in achieving client targets but also increase end-user satisfaction score by offering lesser turn-around time.

… although a full Business Case should include more detail and more clearly address each of the above questions.

Develop Project Plan and Milestones

We should now be in a position where we understand the different requirements, the available resources, and role allocation.

At this point, we can begin to develop a detailed project plan with attainable and realistic milestones.

The first step of our project planning is to develop our project scope. In doing so, it is useful to use both longitudinal and lateral scoping. Longitudinal scoping relates to the length of the process, whereas lateral scoping refers to the breadth.

For example, if I was to analyze the process I use to write articles, the longitudinal scope would stretch from having the idea for the article to the moment the article goes live. That’s the scope of the process I would be investigating; with a clear start and end date.

The lateral scope would be the scope of my investigation. Am I going to analyze only the process of writing this article? Am I going to analyze the process repeatedly over a period of 6 weeks? Am I going to analyze my process and the same longitudinal process of my colleagues over that period too?

Think of it as the scope of the process vs the scope of the investigation.

Once we have this in place, we can look to lay out milestones for when different key moments in the DMAIC process will be achieved. What date will we begin the first step of the Measure stage? What date will we commence the Improve stage? When will we complete the DMAIC process?

It is recommended to set aggressive milestones as efficiency savings benefit from being brought in sooner rather than later, naturally. However, setting milestones which are too aggressive can result in what’s called “band-aid” solutions; where quality is sacrificed in order to reach arbitrary targets.

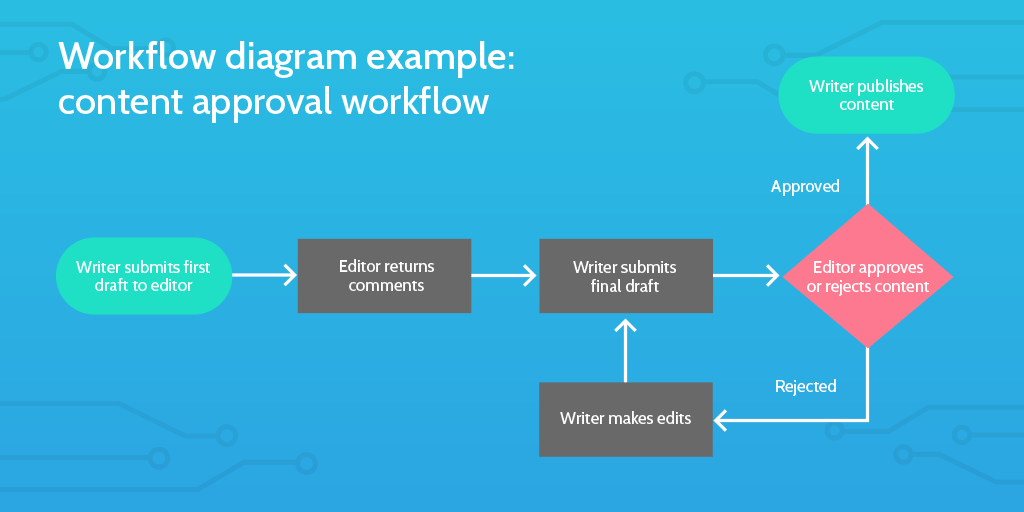

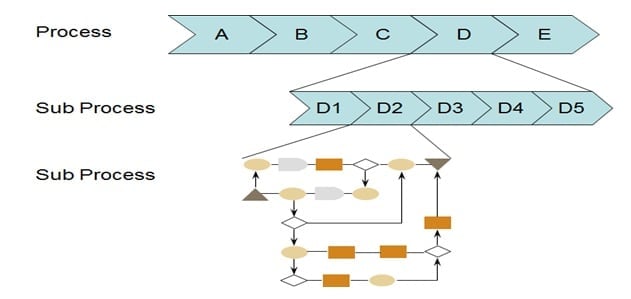

Develop High Level Process Map

In order to have a clear and easy to understand overview of the planned DMAIC process, it is useful to draw up a high level process map.

In order to have a clear and easy to understand overview of the planned DMAIC process, it is useful to draw up a high level process map.

This will serve to demonstrate to each individual player where they fit within the process and how their role relates to the next.

You can use tools like LucidChart to help you create process maps and diagrams simply and effectively.

If you want to read more about process mapping and other in-depth process overview techniques you can read this article of ours: BPMN Tutorial: Quick-Start Guide to Business Process Model and Notation

Measure: Gather the data to understand performance

In the next few subsections we’re going to look at some key Six Sigma terms to understand what we’re measuring, then we’ll develop a research methodology and put it into practice.

This step is all about gathering our data!

Define Defect, Opportunity, Unit and Metrics

At the beginning of the Measure stage, we need to first define what we should be measuring.

To do this, we’ll need to understand a couple of key terms:

- Unit in the Six Sigma context refers to a single item of the product. This is our smallest indivisible point of reference.

- Defect refers to a problem with the product which has arisen from an issue in the process.

- Opportunity refers to the potential points within a process where the possibility for a defect occurring is present.

Once we understand these terms, we can see how they start to fit together to help us make decisions:

- Defects per unit (DPU): number of defects / total number of units

- Defects per opportunity (DPO): number of defects / (number of units x number of defect opportunities per unit)

- Proportion defective (p): number of defective units / total number of units

Work out all the possible opportunities for problems and then begin to filter that list to remove extremely rare events, or to group problems with related causes together. This should give you a workable estimation for your Opportunity.

Develop Data Collection Plan

(Source)

In order for us to make the necessary calculations, we need to gather our data about the process.

To do so we will create a data collection plan which will outline our approach and help us clarify our methods.

This analysis will focus on the minutiae of what exactly we want to measure, how the data will be collected, and the methodology by which we want to handle the data, including:

- How many observations are needed

- What time interval should be part of the study

- Whether past, present, and future data will be collected

If this process improvement project is geared toward internal processes then your customer – another department, for example – might also be gathering this data. This is useful to check because it gives you a control against which you can verify your data once it has been collected, provided any variables are taken into consideration.

The difficulty of this data collection could lie in translating the outcomes into numerical values. For a manufacturing process it is fairly straightforward to understand the process and its outcomes in numerical terms, but less grounded processes can prove trickier. This is why it is important to plan carefully at this stage.

It’s also important to note that while historical data can be used in this analysis, it will likely not have been collected via the same structures and methodologies as you’re creating in this step. This presents a problem as it de-standardizes the data; use historical data with caution.

Having a standardized data collection process gives better data and ultimately better results.

Research 101.

Validate the Measurement System

Well done, you have a research methodology!

But don’t get too excited – we’re not quite ready yet.

Like any piece of research, it is vital to test the methodology – or measurement system – before releasing it into the wild. As a researcher might conduct a pilot study, so too must we test our research methods and review them on a couple of key areas.

There are 4 specific things we want to test before we launch our data gathering project in full:

- Repeatability: If the same operator reaches pretty much the same outcome multiple times on the same item with the same equipment, we can see an adequate level of repeatability.

- Reproducibility: This becomes reproducible if multiple operators measuring the same items with the same equipment end up with the same outcomes.

- Accuracy: It’s a little trickier to be certain on accuracy, but we can broadly say that this can be seen in the difference between an observed average measurement and the associated known standard value.

- Stability: The level of stability is, in a sense, a further extension of repeatability and reproducibility. Stability can be seen by what extent the same operator gets the same outcomes from measuring the same item with the same equipment over a longer period of time. One of the things this stability check is looking for is whether there are external variables which can impact reproducibility over time.

The best way to test your measurement system is to undertake a Gage Repeatability and Reproducibility Study (GR&R), which you can read more about here in this mini library of GR&R materials from iSixSigma.

Once we’re sure that our methodology is clearly defined and we’ve validated our measurement system, we can begin to collect our data!

Collect the Data

Not too much needs to be written about the actual data collection as all the previous steps have been building up to this point.

The key thing to remember is simply to stick to your plan as you defined it and to adhere stringently to the research practices and methods which you validated.

The Black Belt should be the primary point of command in this data collection process, making sure that all procedures are adhered to. The Black Belt needs to take responsibility for all the Green Belts understanding the necessary steps, definitions, and goals.

To use a sporting analogy, the players are Green Belts, the captain is the Black Belt, the Process Owner is the head coach, and the Champion is the club chairman. Right now, it’s game day and on the pitch the captain needs to lead by example.

(Source)

Begin Developing Y=f(x) Relationship

This is where things will start to sound a little technical. But don’t worry, we’ll walk through it.

Think of Y as representing the output of a process. It doesn’t technically refer to Yield at this point, but we’ll come to that later on.

So, Y is the output of a process and X is the input. The f represents the function of the variable X.

Y is the output we care about and X can be multiple different variables which impact on Y. Here’s an example from iSixSigma:

For example, if you call your major department store to ask a question, the ability to have your question answered (Y) is a function (f) of the wait time, the number of people answering the phones, the time it takes to talk with the representative, the representative’s knowledge, etc. All of these X’s can be defined, measured and improved.

At this point, you don’t need to work out the Y=f(x) relationship in full, but you can start bearing it in mind. It is considered best practice to keep work oriented around the Y=f(x) formula.

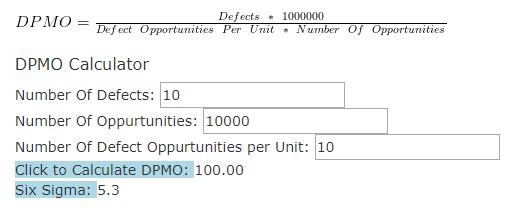

Estimate the Sigma Baseline

Again, we can prepare ourselves for the future stages by running a quick calculation.

To work out your Sigma, you can calculate your Defects per Million Opportunities (DPMO) and run it through a handy conversion chart.

You calculate your DPMO by simply multiplying your DPO by a million.

To make it all easier, just use this straightforward Sigma Calculator.

You can see an example calculation in the image below.

A sigma of 5.3 is very good, but there is still a space of 0.7 for improvement to reach our Six Sigma goal.

Analyze: Understand where the problems in your process lie

The analysis step is where we have to dig in deep into the existing processes and work out the root causes of the problems.

Finding these causes should allow us to tackle them in our Improve stage. It’s all about finding the pertinent Xs for the Y=f(x) formula we mentioned above.

Define Performance Objectives

Having measured the process in the previous steps, we should be in a position where we roughly know what it is we want to improve.

Before we begin analyzing in depth, we should lay out what our objectives are so that these goals can guide us. Think through the process and the data you have to calculate what the key performance objectives would be.

These objectives can prove slightly flexible as your analysis moves forward but it is always better to start with clear goals.

Develop a Detailed Business Process Map

We’ve already mentioned in this article how you can use strategies like BPMN to map business processes, but it isn’t the only approach. A very similar approach might be to use an As Is Process Map, which can incorporate BPMN elements but is not defined by it.

This business process map can help show us the granular make up of the company process we are analyzing and reveal factors like which process steps are value added and which are non-value added. Identifying non-value added steps at this stage opens up the potential for us to eliminate waste in our process improvements.

This process map should be analyzed for potential areas of variation. These variations, or potentials for variation, will likely lead us to the root causes behind our Opportunities (for defects).

An example Six Sigma As Is Process Map from Six Sigma Institute is shown below.

Determine Root Cause(s)

There are many different techniques you can utilize in order to attempt to dig down into what the root causes of a variation are, and we’re going to look at three specific examples of methods you can use:

- The 5 Whys Analysis

- The Fishbone Diagram

- The Pareto Chart

The 5 Whys Analysis

This is a fairly simple technique to start you off. The idea is that you ask “why?” five times to dig deep into the root of a problem. The logic behind it is that in the first few questions you will find one of the causes of the problem, and by the 5th question you will see the process failure behind that problem. This example from Wikipedia does an excellent job of conveying it:

The vehicle will not start. (the problem)

- Why? – The battery is dead. (First why)

- Why? – The alternator is not functioning. (Second why)

- Why? – The alternator belt has broken. (Third why)

- Why? – The alternator belt was well beyond its useful service life and not replaced. (Fourth why)

- Why? – The vehicle was not maintained according to the recommended service schedule. (Fifth why, a root cause)

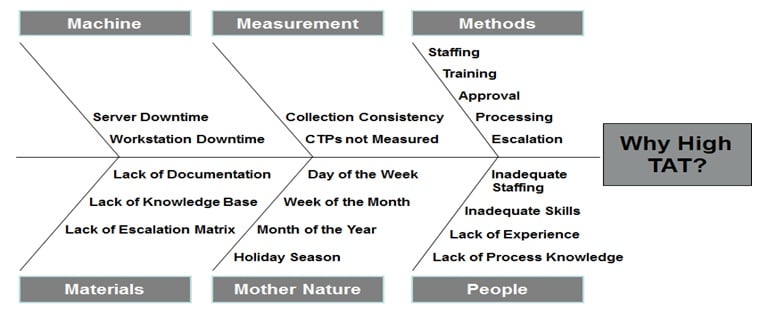

The Fishbone Diagram

This approach takes 6 different variable categories and feeds the information together to help you visualize what factors within the business operations are contributing collectively to the same problem. One of the advantages of this method is that it forces us to view the problem holistically, rather than the potentially blinkered approach of the 5 Whys.

According to the Six Sigma Institute, the 6 key variables are:

Machine: This category groups root causes related to tools used to execute the process.

Material: This category groups root causes related to information and forms needed to execute the process.

Nature: This category groups root causes related to our work environment, market conditions, and regulatory issues.

Measure: This category groups root causes related to the process measurement.

Method: This category groups root causes related to procedures, hand-offs, input-output issues.

People: This category groups root causes related people and organizations.

They’ve also produced this neat little graphic of a company using the Fishbone Diagram to understand what factors contribute to a hypothetical company’s High Turn Around Time.

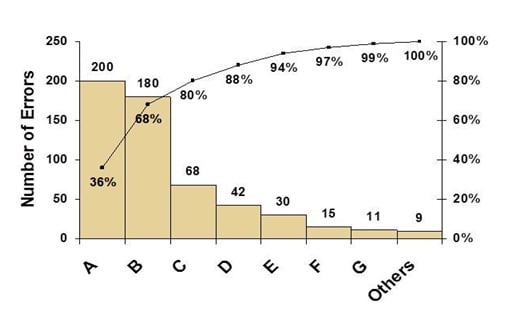

The Pareto Chart

You might already be familiar with the Pareto Chart. The purpose of the Pareto approach for us is to understand which variations have the highest impact on our output; it helps us determine the Vital Few.

If the other techniques assist in finding variations and identifying potential root causes, the Pareto Chart allows us to prioritize which root causes to target first to have the greatest impact on improvement in relation to our stated objectives.

Here’s the Six Sigma Institute’s example Pareto Chart.

Determine the Y=f(x) Relationship

Once we’ve identified the Vital Few, we’re able to return to our Y=f(x) formula.

Remember, Y is simply a variable which is defined by the relationship between our Xs and their functions. So, if we want to improve Y then we should identify which X has the biggest impact on the Y value and improve that X.

Our ultimate aim is to better understand the relationship represented by this formula and to round out errors from it. For example, there may be an X which has a major impact on Y but is not due to a process problem but simply a natural or unchangeable element of the manufacturing process. In which case, we need to identify that this particular X, while important, is not one we can tackle as part of our process improvement.

Our job isn’t just to find the Xs which contribute to Y, but to find the right Xs.

This image from iSixSigma helps to illustrate how that process runs through the heart of our investigation.

Improve: Work out how defects could be reduced

The improve section of the DMAIC process is where we take advantage of all the preparatory work we’ve done so far.

Our goal here is to highlight our Xs and look to maximize the performance of those inputs. The key element of the Six Sigma approach is the importance of doing this through mathematical and scientific means.

Perform Design of Experiments

Our Design of Experiments (DOE) is probably the key step to getting this right and achieving the improvements we want to make.

This DOE approach highlights the relationships between different Xs and the output (Y). Factorial experiments are one of the crucial methods to show how different Xs can relate to each other.

On iSixSigma there is a useful example about baking a cake and how a DOE can be used to optimize the process. We’ll look to summarize DOEs with reference to that baking related example.

First off, let’s look at some of the key terminology then we’ll jump into a two-level factorial design:

Controllable input factors.

These are your Xs. These are variables within the process which we can experiment with and change. In baking a cake this might include the number of eggs or the amount of flour.

Uncontrollable input factors.

These are variables which may have arisen earlier in the investigation but we can’t act upon. In a baking scenario it might refer to the resting temperature of the kitchen. Or, to make an infrastructural analogy, the capacity of the oven – a factory might produce more goods if it was bigger, but increasing its size might be prohibitively expensive, for example.

Responses.

This is the extent to which the output services the customer needs and wants. In baking this could refer to a simple taste test. This factor, like the others, would need to be quantified. “Good or bad” is not enough; a score out of 10 from the customer averaged out as a final percentage figure from all testing would be a more effective approach.

Hypothesis testing.

In a hypothesis test there are two potential outcomes: null and alternative. A hypothesis test focuses the accuracy of a hypothesis with each test. The null hypothesis is valid if the status quo is true. The alternative hypothesis is true if the status quo is not valid. We get our results by analyzing significance which means results are based on probabilities – so get your p-values at the ready!

In baking, we might have a brand name cake mix which declares that it takes on average 30 minutes to bake. You might classify this as your hypothesis. The null hypothesis would be that the average amount of time it takes to bake this particular cake is in fact 30 minutes. But you can’t have a null hypothesis without an alternative hypothesis. You should select your alternative hypothesis in advance in order to construct the experiment properly. We have 3 choices of alternative hypotheses to choose from:

- The average time to bake the cake is not 30 minutes (not equal)

- The average time to bake the cake is more than 30 minutes (greater than)

- The average time to bake the cake is less than 30 minutes (less than)

The formula for checking whether the average baking time is 30 minutes or not would be:

Ho:μ=30 versus Ha:μ≠30

Blocking and Replication.

Blocking and replication are fortunately much simpler concepts. Blocking is just about making sure the conditions for each experiment are the same; use the same stirrer and tray to bake the cakes with. And replication is simply the principle of running the experiment multiple times to gain more accurate results – a great excuse to bake extra cakes.

Interaction.

This refers to a situation where an experiment has three or more variables and the simultaneous influence of two of the variables on the third is not additive. Sadly, my knowledge of baking has let the analogy down on this one. My bad.

Two-Level Factorial Design

This experiment will be constructed to look at 3 variables where each can be tested at a low or high level. This kind of structure gives us the ability to investigate deeper into a process yet is still simple enough for us to see how the experiment works.

Consider our process to be baking a cake. Our three variables are the Vital Few we identified in our Analysis stage. They are:

- Brand of flour

- The temperature of baking

- The baking time

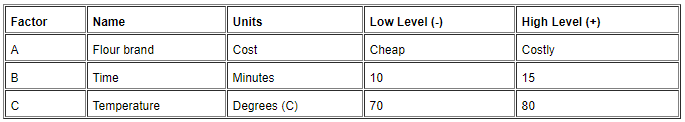

We’re going to look at each of the variables with both high and low settings. The table below should outline these key bits:

Our two outputs which we’re going to measure against will be taste-testing and crust-formation, representing our customer’s needs and wants.

Taste-testing will be a score out of 10 with the average multiplied by 10 to give a percentage result. The crust-formation will be measured by weight with lighter crusts being the goal.

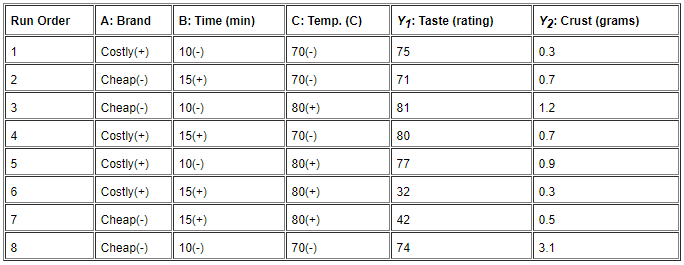

From all of our cake related testing, here are the results:

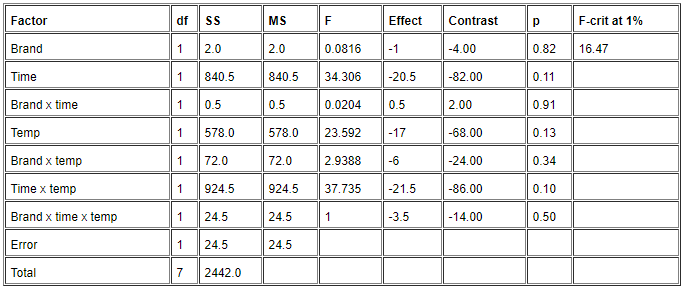

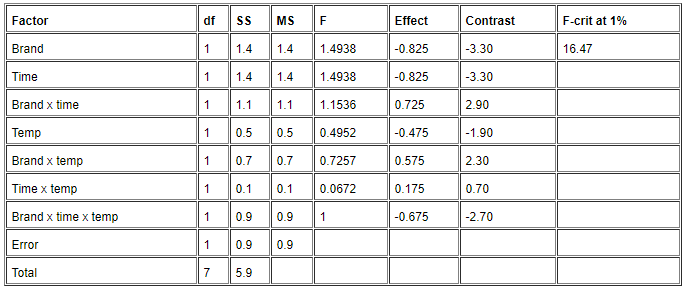

We then want to run these results through something called an ANOVA table. An ANOVA table stands for an Analysis Of Variance and is used when comparing 3 or more groups of numbers. We’re going to look at two different ANOVA tables; one for the taste rating and one for the crust score – representing the two things our customers care about.

The simplest overview of ANOVA tables can be found here, and it gives us this handy summary:

It doesn’t look at the differences between pairs of group means; instead, it looks at how the entire collection of group means is spread out and compares that to how much you might expect those means to spread out if all the groups were sampled from the same population (that is, if there were no true differences between the groups).

Which means roughly that our ANOVA table on taste testing will look at how all the results impact on taste to see how each group should impact on taste and then tells us how each group performs relative to that expected impact; higher or lower impact.

All this is conveyed through the F Ratio which tells us about the levels of variance between the groups relative to the variance within the groups.

If the null hypothesis is true, then F should be close to 1. The further F is from 1 the more it suggests the alternative hypothesis to be true. In the case of our experiments, the higher F is the more important an input factor is on output.

Here is our ANOVA table for the taste testing:

What we can tell straight away is that Time and, to a slightly lesser extent, Temperature have a large impact on the output.

This can be even further understood through visualizations of the data. Here is the taste scores on the y axis with the two time settings on the x axis and the behavior of high vs low temperature plotted on the graph:

So, we know that time and temperature are critical for taste, but what about crust formation? According to the F values in the table below, none of our 3 variables were statistically significant. Perhaps crust formation is more closely related to the number of eggs?

Develop Potential Solutions

With a strong working knowledge of your business processes and systems, you’re now able to develop solutions which can tackle the key issues hindering output within the business.

The results of the DOE tests can also assist in that optimization process as the visual graph above shows. This data gathered from varying iterations of your key potential Xs, provides a series of potential avenues to explore.

When constructing the different options for solutions make sure to propose enough to test and evaluate.

These solutions should be rooted in the deep analysis you’ve undertaken.

Assess Failure Modes of Potential Solutions

Failure Modes and Effects Analysis is a method which can identify risk ahead of time. This quasi-predictive process analysis tool can help you evaluate the details of your proposed business process solutions.

You can read more about FMEA in a previous article of mine: FMEA: The Analysis Method to Prevent the £100m British Airways Catastrophe.

I’ve also created this actionable template to guide you through the process of running a failure modes and effects analysis. You can use it as a simple guide or add it to your Process Street account for free.

Validate Potential Improvement by Pilot Studies

Lastly, to complete the Improve section of our DMAIC process, it’s important to test out the solutions which have made it to this point.

The few solutions you’re left with can be part-deployed live in controlled conditions as part of a pilot study to gage their relative effectiveness.

The Process Owner can map out the design for these pilots and the Black Belt can manage the pilots in practice.

The performance of the proposed solutions should leave you with an overall best performing process improvement solution based on output. To measure these proposed solutions effectively, try to calculate the Sigma Baseline as before.

Control: Plan out how you will implement your solutions

The Control section is all about putting processes and procedures in place to make sure the implementation of the new solution runs smoothly and can be tracked and optimized over time.

Ultimately, the rest of the DMAIC process prior to this stage was dedicated to the Xs whereas the Control stage is devoted to the Y; the output.

Standardize and Document Processes

This is the most obvious step and echoes what we always discuss in our articles on Process Street.

To implement a new process, you need to make sure each step is documented thoroughly and it is mapped out in a way which is actionable and provides space for measurement.

These processes should be consistent at all times and this can be achieved through simply standardizing approaches across teams.

You can use software like Process Street to assist you in standardizing and documenting processes. Process Street can also be used for managing standard operating procedures held to ISO specifications. If you’re a large company which requires ISO adherence, you can check out this public Process Street template below to help illustrate how you could structure an ISO-9001:2015 QMS Mini Manual on our system in the cloud for team use:

Prepare Implementation Plan

This task may be planned by the Process Owner and implemented by the Black Belt, though different companies might look to do it in different ways.

The important factors here concern how the new process can be effectively integrated into the company workflow.

- What teams within the company need to adapt to suite the new process?

- Does this change need to be simultaneous or can it be rolled out iteratively?

- Do we require multiple Six Sigma advocates to embed into each team for implementation?

- What budget or resources does the Champion need to secure to ensure effective rollout?

- When does implementation begin?

- What is the target date for complete implementation of the new process?

All of these questions should be answered in the drafting of a report so that the company can act upon our DMAIC work.

Additionally, it is important to create a Response Plan which tackles the what ifs of managing the process. This would come under the realm of risk management as it looks at putting processes and procedures in place for if problems occur within the process or are seen in the output.

Implement Statistical Process Control

Once your process is standardized and documented, implementation must undergo monitoring. One industry standard approach to process monitoring is Statistical Process Control.

Statistical Process Control (SPC) was originally developed in 1924 by Walter Shewhart. It is used to monitor and control the output parameters of a process.

A short definition is given to us by InfinityQS:

Quality data in the form of Product or Process measurements are obtained in real-time during manufacturing. This data is then plotted on a graph with pre-determined control limits. Control limits are determined by the capability of the process, whereas specification limits are determined by the client’s needs.

This basically means that we gather quantifiable data about the process and look at the size of the output vs the quality of the output.

On the graph you make, you’ll set control limits. These define an acceptable range which your process should operate within. When data points start appearing outside of this range, this acts as a red flag to show us that variations are occurring.

If done properly, these red flags should catch variations before variations result in defects; allowing us to tackle process problems before they result in output or product problems.

At this point, your Six Sigma project has been a success!

(Source)

Use DMAIC to help you reach your Six Sigma goals

Once you’ve successfully undertaken your DMAIC project, you might think your job is done.

It is not.

A crucial part of any lean Six Sigma process is to keep the principle of continuous improvement in mind. Within lean philosophies we might refer to this as Kaizen. In Japanese this translates to “change for better”, but within the world of process improvement it has come to reflect a continuous iterative model for gradual change.

Once one Six Sigma project is done, it is likely time to move onto the next.

If you can reach your goal of Six Sigma then your processes will be functioning at the highest industry standards and your business will be in the best position it can be.

It’s up to you to make sure the rest of the business runs as effectively as your best processes!

Are you a Six Sigma enthusiast? Have you employed DMAIC in your business before? Let me know in the comments your experiences, tips, and tricks!

Workflows

Workflows Projects

Projects Data Sets

Data Sets Forms

Forms Pages

Pages Automations

Automations Analytics

Analytics Apps

Apps Integrations

Integrations

Property management

Property management

Human resources

Human resources

Customer management

Customer management

Information technology

Information technology

Adam Henshall

I manage the content for Process Street and dabble in other projects inc language exchange app Idyoma on the side. Living in Sevilla in the south of Spain, my current hobby is learning Spanish! @adam_h_h on Twitter. Subscribe to my email newsletter here on Substack: Trust The Process. Or come join the conversation on Reddit at r/ProcessManagement.