What do Three Mile Island, the Hubble Telescope, and the Ford Pinto have in common?

They all had fatal flaws caused by their substandard quality management systems.

While most failures that could be solved with a thorough QMS don’t result in a combined $3.9 billion in damages and 180 deaths, it’s impossible to argue that such a system couldn’t also bring massive benefits to your own business.

To name but a few, these effects include:

- ISO compliant

- Being more productive

- Becoming more efficient

- Reducing employee turnover

- Systems for measuring and tracking successes and failures

- Better customer loyalty

- Not causing a nuclear meltdown

Sadly, quality management system explanations tend to come with a lot of jargon and dry text. That’s why we here at Process Street bring you this guide on how to create and implement one.

A working example for those experienced

In this post, I’m going to explain what a QMS is, how it functions, and how you can deploy it. However, you might already know all that – and you’re just looking for the fine detail or a working example.

If that’s you, then you can find this template right here which provides you with the whole outline structure of a Quality Management System Mini-Manual to the standards of ISO:9001:

And if you need that little bit more guidance, you can find a fully completed example version of this mini-manual right here below:

Back to quality management systems!

What is a quality management system?

A quality management system is exactly what it sounds like; a system which lets you define what “quality” means to your business, unite it under that description, design processes to help achieve that goal, and continuously improve your business.

It’s a way to make sure that your company is performing well and serving your customers’ needs in a formally documented (and measurable) system.

It’s also a core aspect to making sure that your organization is ISO:9001 compliant.

While a QMS alone won’t provide you with the certification, the idea of ISO is to be able to prove that your company meets certain standards of performance. If you’re running your operations well and are able to prove as such (by meeting their requirements), then the certification can even be used as a selling point for your business.

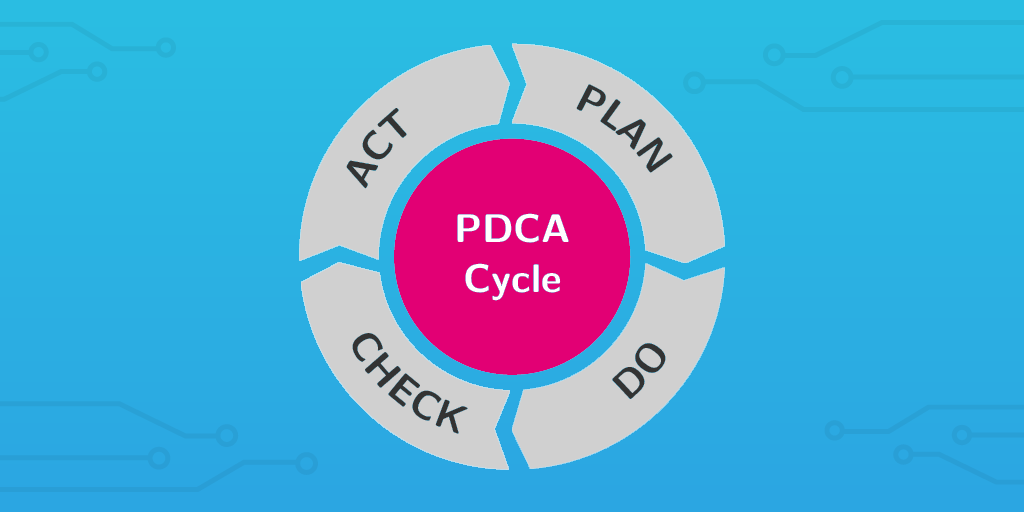

The specifics will be unique for each business (as it’s all about documenting and improving your business), but the vast majority of quality management systems contains the following structure:

- Plan

- Do

- Check

- Act

Again, descriptions of these steps often come with a lot of useless jargon, so let’s break them down more succinctly.

The structure of a quality management system

Plan

Planning is, arguably, the largest part of creating a quality management system, simply because it involves going through everything related to what your company values – what it deems to be “quality”.

For a quick list, you need to lay out:

- What “quality” means

- How that relates to what your company does

- The structure of your organization

- A quality policy that your company can unite around

- What the scope of your QMS is

- What processes are covered in the system

- How those processes operate/are conducted

- Quality objectives to aim for

- Risks and opportunities to (and created by) the QMS

- A plan to continually improve on your organization and strive to reach your quality goals

Yes, that’s the quick list.

This lets you see and demonstrate to others how your organization operates, and to how successful it is in achieving a specific quality standard. Coupled with giving you a set of specific goals, areas, and methods to improve your performance, and you have a system that gives you practically no reason to do anything but succeed.

Plus, if you’re going for an ISO:9000 certification, documenting all of the above in a way that you can present forms a massive part of your proof for that title.

Unfortunately, we’re far from done.

Do

Planning a fancy system is all well and good but for it to have any effect you actually need to execute it. That’s where the “Do” step of Plan-Do-Check-Act (PDCA) comes in.

This is pretty much where you take everything from your plan and apply it to the processes involved in serving your customers, be it in creating products or providing a service for them. Even if you can’t directly control every aspect of a process (eg, externally sourced processes/products) you need to have checks in place to make sure that the result of them measures up to the same quality standard you subject yourself to.

Your processes should already be documented (either from your plan or by having documented processes in general), so you should be able to directly apply the improvements you identified in your plan. The key is doing so while making sure that the results are measurable and that any actions taken are carefully controlled with an intended purpose.

In other words, you can’t try something for the hell of it.

You need to have a reason for every change you make in your plan detailing what the predicted effects will be and how it contributes to your quality goals.

Finally, you need to make sure that there’s a system in place for dealing with anything that doesn’t meet your expectations. Call it a failsafe or damage control, either way, you can’t fly by the seat of your pants if something goes wrong.

Check

Your QMS plan has been deployed but (sadly) that doesn’t mean you can take its effects for granted. Part of any good QMS (and any business looking to become ISO:9000 certified) is measuring, tracking, and analyzing everything under the scope of your system.

The checking stage isn’t just about measuring results for your own analysis though. It’s about making sure that you can present these quality results to others to prove how well your business is performing.

Much like your quality management system as a whole, the specifics of how you go about tracking and analyzing the performance of your various processes will depend on your organization. The main point is that you need to have some way of doing so and being able to demonstrate the results.

This isn’t limited to hard processes either. You also need to have a method for measuring your customers’ satisfaction and whatever your company defines as “quality”.

Here’s a few ways you can go about this “check” step:

- Customer satisfaction surveys

- Internal audits

- Dedicated tools to make tracking easier (CRM, BPM software, etc)

- Inventory logs

- Delivery times and averages

- Floating stock levels, etc

So, you’ve got your results but what do you do with them? Well, you…

Act

During the “Act” phase you need to take action on any problems that you found after deploying your initial plan. Think of this as correcting any mistakes or oversights in the quality management system thus far.

However, “Act”ing is also about improving your processes based on your results. You’re not just fixing what’s broken but improving what didn’t go as well as you’d like.

It’s important to remember that these changes aren’t typically going to be system-wide or big enough to affect much outside of their direct environment. Large-scale changes that play into the QMS as a whole need to be approached in the “Plan” and “Do” phase where they can be given the attention they need and deserve.

In other words, you need to be very careful about the actions you take here. If they’re small enough to be deployed with certainty that there will be no far-reaching or unintended effects then record what you’re doing and deploy them.

If, however, you’re making large changes that need extra thought and effort behind them, these should still be recorded but not immediately acted on. Instead, these should be some of the changes that you base your system around in your next “Plan” phase.

Speaking of which…

Repeat

The quality management system can (and should) be repeated pretty much ad infinitum, much like other similar systems for continuous improvement. Typically, your “Check” and “Act” phases will have highlighted enough areas for improvement for you to start a new cycle straight away.

If you can’t immediately identify an area for improvement, first off, congratulations! Second, start brainstorming some ideas for how to improve your company based on your quality goals – it never hurts to keep moving and keep improving.

So there you have it – the structure of every good quality management system from start to finish. Still, despite knowing what one is doesn’t mean you know how to make one or even necessarily what it’s made of.

Let’s rectify that right now.

Elements of a quality management system

Quality management systems are made up of the following elements:

- A scope statement

- Quality guidelines (or a manual)

- A full organizational structure

- Documented processes

- Further internal documentation

- An improvement system

Let’s go over these individually.

Set the scope

When developing systems for your QMS, the scope is vital in letting anyone and everyone know precisely what is included in it and what isn’t. However, unlike a process’ scope statement (which can be a nightmare to pin down) the QMS scope tends to be fairly simple.

In short, the scope of a quality management system is usually your entire organization.

Unless you have a good reason for doing so, it makes very little sense to apply the QMS to the majority of your business while leaving potential weaknesses in the form of untracked, unimproved areas.

If it’s worth doing and has any connection to your customers’ satisfaction or what you’ve defined as “quality”, it should be part of the scope of your QMS.

If, however, there is an element which isn’t related and you wish to keep separate, you need to have a log of exactly what is being excluded and (preferably) a reason why.

Create quality guidelines (or a manual) to keep goals clear

Quality guidelines set out exactly what your company and customers value and how that’s reflected in your policies and procedures.

Basically, you’re stating what your company and customers’ idea of “quality” is and how you’re going to reach those quality goals.

A quality manual, meanwhile, is a combination of your guidelines and the structure of your QMS as a whole. It’s more comprehensive in that it needs to show how your quality guidelines interact with the rest of your organization and the processes you carry out, thus you need to have carried out at least one run of your QMS’ Plan-Do-Check-Act cycle in order to create it.

Check out this example below to see what a quality management system mini-manual might look like. We’ve used the fictional company “Brightstar marketing” as a base.

If you’d like to use this template to create your own QMS manual, check out this free ISO-9000 Structure Template for a blank version of the example above.

Use an organizational structure to keep transparency high

An organizational structure chart has many benefits and is an absolute must-have for any decent quality management system.

All you have to do is lay out everyone in your organization and what they do, including their job titles, what the chain of command is, and what everyone’s responsible for.

For example, in your marketing department you could have the head of Marketing at the top, below them you could branch out to various heads of departments, then into your editors, then your writers and other content producers, and then any assistants or VAs.

This gives everyone in your business a document they can refer to if it’s ever unclear as to who they need to talk to about a specific issue, and helps to remind everyone of who is working around them and relying on them for particular tasks.

It’s also a great way to make sure that everyone knows what they’re accountable for and keep everyone on task.

Document processes to show how you’ll achieve your goals

If you’ve been with us for a while, you’ll know just how important it is to document your processes.

No matter what you do, it’s vital to have a repeatable set of instructions which you and your team can follow to complete any and every task that needs to be done more than once.

This prevents any chance of human error (be it negligence or plain old forgetfulness) from sneaking in, and even lets employees perform tasks better and more efficiently than they would be able to under their own steam. Not to mention

That’s where Process Street comes in.

Process Street makes it easy for you to document, manage, track, and analyze your team’s processes and workflows. By recording process templates and tracking progress over individual checklists of those templates, you can give your team a definitive guide on how to complete their tasks to a high standard while also tracking their progress.

Sign up for a free account today here.

Make an improvement system to consistently get better

You can’t make improvements to your business and regular workflows by changing something and hope it gets better. That’s the kind of lack of planning which caused the Hubble Telescope’s mirror to be manufactured in the wrong shape (leading to a $25 million lawsuit).

No, you need to have a set system for continuously improving elements that your QMS highlights as needing the attention.

The method itself doesn’t particularly matter, so long as you’re clearly analyzing what changes should be made, what you’re expecting to happen as a result, and how you’re going to track the effects.

As for the type of method or school of thought to follow, there’s a span to choose from:

- DMAIC

- Agile

- Incremental continuous improvement

- Breakthrough continuous improvement

For more help on the topic, check out any of our articles on the subject:

- What Continuous Improvement Is (and How to Use It)

- Process Improvement: Stop Bad Processes Killing Your Business

- How to Use The Deming Cycle for Continuous Quality Improvement

- 8 Critical Change Management Models to Evolve and Survive

- Little’s Law: How to Analyze Your Processes (with Stealth Bombers)

- DMAIC: The Complete Guide to Lean Six Sigma in 5 Key Steps

Use internal documentation to stop repetition

Finally, it’s vital that you document your QMS (along with pretty much everything else) in a system that lets anyone find information that they may need access to.

For example, your Marketing Director will need access to all of your marketing processes, data, your QMS, organizational structure, and so on. Meanwhile, a VA will only need to have access to the processes they directly carry out, the data that’s immediately relevant to them, the QMS manual (for an overview of it) and the org structure.

This is all about making sure that you’re recording everything in a way that makes it easy to find information wherever it may be needed while controlling things like the permission levels of your team so that you can still protect sensitive information.

Here at Process Street, for instance, we use Airtable to store the majority of our data (blog posts, keywords, tasks, competitors, and much more), Close.io as our CRM, and our own product to document, manage, and track all of our repeatable processes.

How to implement a quality management system

You know what a quality management system is, how they’re structured, and what they’re made up of.

Now it’s time to learn how to implement one from scratch.

Here I’ll go over:

- How to design your quality goals

- How to deploy your plan effectively

- How to measure your results to later improve them

- How to review your results without losing sight of your goals

Design with your goals and customers in mind

Defining what “quality” means to your team and setting goals according to that can be a massive headache. Sadly, it’s also incredibly easy to mess up.

The trick is not thinking from the point of view of your company. It sounds stupid but hear me out.

Most companies would be safe in assuming that “quality” to them would be shown through their market share, profit margins, overall earnings, and so on. However, that’s not how the people who really matter perceive it.

You need to look at things from your customers’ point of view. They’re the ones who you’re trying to sell to, and if you as a company aren’t providing them with the kind of quality that they want out of your product or service, they’ll look for someone else to do just that.

This can be anything from product quality (reliability, efficiency, design, etc) to customer service and brand appeal. The key is talking to your customers and seeing what they define as “quality” and then relating that back to your organizational structure and product.

Only with that knowledge and context can you create quality goals which benefit your company while getting the greatest positive impact from your customers.

Deploy in small chunks

Trying to deploy your entire QMS plan at once will result in pure, unadulterated chaos. Considering you’re trying to improve your organization, it makes sense to want to avoid that particular bonfire.

Instead, the key is taking a leaf out of any decent change management model and deploying changes slowly and in smaller parts.

Break your changes down into specific processes and then again into smaller sub-processes which can be deployed without disrupting other related systems. That way you’re not putting overwhelming pressure on your team to get used to everything being new at once.

Be sure to talk to your team about the changes too. After all, they’re going to be the ones that’ll need to carry them out and uphold them until they become the new norm.

Convince them why the changes needed to be made, why they’re important, and how it will improve their job. Make sure everyone knows exactly what changes they will need to make in their personal workflows and what those around them will be changing too (especially if it could affect their own tasks).

Change doesn’t come naturally. Before you can sell your customers on the idea of a better company, you need to do the same for your employees and colleagues.

Measure to monitor success

I’ve made this point several times in this post already but there’s no point in developing and deploying a quality management system that you can’t measure. However, that doesn’t mean you should be working yourself to the bone in the pursuit of that.

If you don’t already have a system in place to let you easily measure and analyze the performance of your organization, you need to take the time to plan out such a thing before you start planning anything. After all, you need to know your current performance in order to see how you can improve.

There aren’t many specific tips I can give (much will depend on your organization, the structure of it, what you do, your team size, and so on) but I will say that our team has found that the easiest way to monitor your success is to use some of the best business apps which natively have that kind of reporting feature.

It might seem obvious but it really is that simple.

Tools like PersistIQ are stellar for instant feedback on your email campaigns, Process Street has a template overview tab where you can see a spreadsheet-style summary of what everyone’s been doing and the progress they’ve made, and tools like Airtable can be used as a database to store pretty much all of your information in one place for easy access.

You could even use services like Zapier to do a bit of database automation and get rid of the tedious tasks such as data entry and management.

Review based on your goals

You can’t review your results in a vacuum – that’s a great way to end up with flawed conclusions.

The best way to consistently improve and reach your goals is to review your results in relation to your goals and your previous results. That way you can see how successful your efforts were towards a set milestone while also getting a sense of your progress towards it over time (and compared to previous iterations).

However, it’s also important to be realistic.

Your quality goals aren’t necessarily the same as those that are immediately healthy for your bottom line. Whether you need to use more expensive tools or materials or spend time and money training up your employees, it’s entirely possible that your profits or productivity could dip slightly while you’re moving towards your quality goals.

The trick is balancing the practicality of your changes with progress towards said goals. They’re important to achieve and fantastic for the long-term health of your business but you don’t want to be taking too big of a hit all at once.

Remember; you can always break down your changes into smaller processes that can be deployed while being less disruptive to your day-to-day business.

Striving for quality is never a bad thing

There you have it – a full rundown of what a quality management system is, how it’s structured, how to create one and then how to deploy it. Armed with that knowledge, it’s time to go out and try it for yourself!

As a final note, if you’re interested in going for an official ISO:9000 certification, check out this list of items that you will need to present in order to do so. Many are items directly involved with the QMS itself, so creating one will still give you a massive head-start.

If you’d like to read more on related topics, check out our related posts below:

- Agile ISO: How to Combine Compliance with Rapid Process Improvement

- How to Write an Actionable Policy and Procedure Template (ISO Compliant!)

What would you define as “quality”? Have any special tips for how to handle a QMS? I’d love to hear from you in the comments below!

Ben Mulholland

Ben Mulholland is an Editor at Process Street, and winds down with a casual article or two on Mulholland Writing. Find him on Twitter here.