Get work done right, and right-on-time with our industry leading BPM platform.

16 Best Manufacturing Management Software To Transform Your Processes

Manufacturing management software brings efficient and effective management of operations.

Whether you’re a small manufacturer seeking to streamline operations or a large enterprise aiming to maximize productivity, the right software can help you succeed.

Manufacturing management software plays a pivotal role, offering tailored solutions to streamline processes, enhance productivity, and ensure quality across every production stage.

That’s why we’ve compiled a list of the best manufacturing software, so read on to find the right one for you.

- Inventory management software for manufacturing

- Manufacturing operations management software

- Manufacturing process management software

- What is manufacturing management software?

- Key features to look for in manufacturing software

- What’s the difference between ERP and MRP?

- What are the 5 types of software used in manufacturing?

- Do I need manufacturing management software?

16 best manufacturing management software

Inventory management software for manufacturing

Fishbowl Manufacturing

Fishbowl Manufacturing is a comprehensive inventory management software for manufacturing businesses. It offers features such as order management, inventory tracking, manufacturing process management, and integration with various accounting software.

Pros: Fishbowl Manufacturing provides robust inventory tracking capabilities, integrates seamlessly with popular accounting software like QuickBooks, offers advanced manufacturing features such as bill of materials and work order management, and provides excellent customer support.

Cons: The user interface can be a bit complex for new users, and the software may require some time for initial setup and configuration.

Best for: Fishbowl Manufacturing is ideal for small to mid-sized manufacturing businesses looking for a comprehensive inventory management software for manufacturing that integrates well with their existing accounting software.

Why it’s good: Fishbowl Manufacturing stands out as a top choice for manufacturing management software due to its extensive feature set tailored specifically for manufacturing businesses, seamless integration with accounting software, and reliable customer support.

NetSuite Manufacturing Edition

NetSuite Manufacturing Edition is a cloud-based inventory management software for manufacturing businesses. It offers features such as supply chain management, production planning, inventory tracking, and order management.

Pros: NetSuite Manufacturing Edition provides real-time visibility into inventory levels and production processes, offers advanced forecasting and planning tools, integrates seamlessly with other NetSuite modules for finance and CRM, and provides scalability to accommodate business growth.

Cons: The cost of implementation and customization can be high, and the software may require significant training for users to utilize its full capabilities effectively.

Best for: NetSuite Manufacturing Edition is best suited for mid-sized to large manufacturing businesses looking for a comprehensive cloud-based solution that can manage their entire manufacturing process from production planning to order fulfillment.

Why it’s good: NetSuite Manufacturing Edition is a robust inventory management software for manufacturing that offers extensive features tailored for manufacturing businesses, seamless integration with other NetSuite modules, and scalability to support business growth.

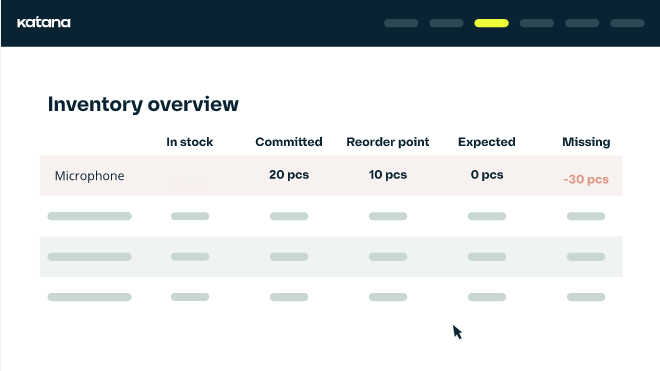

Katana

Katana is a cloud-based inventory management software designed specifically for small manufacturers and crafters. It offers features such as real-time inventory tracking, production scheduling, and order management.

Pros: Katana provides an intuitive and user-friendly interface, offers seamless integration with e-commerce platforms like Shopify and WooCommerce, provides real-time inventory updates across all sales channels, and offers affordable pricing plans.

Cons: Katana may lack some advanced features required by larger manufacturing businesses, and the reporting capabilities may be limited compared to other solutions.

Best for: Katana is ideal for small manufacturing businesses and crafters looking for user-friendly and affordable inventory management software that integrates well with their sales channels and offers robust inventory management features.

Why it’s good: Katana is a standout choice for small manufacturers and crafters due to its intuitive interface, seamless integration with popular e-commerce platforms, real-time inventory updates, and affordability.

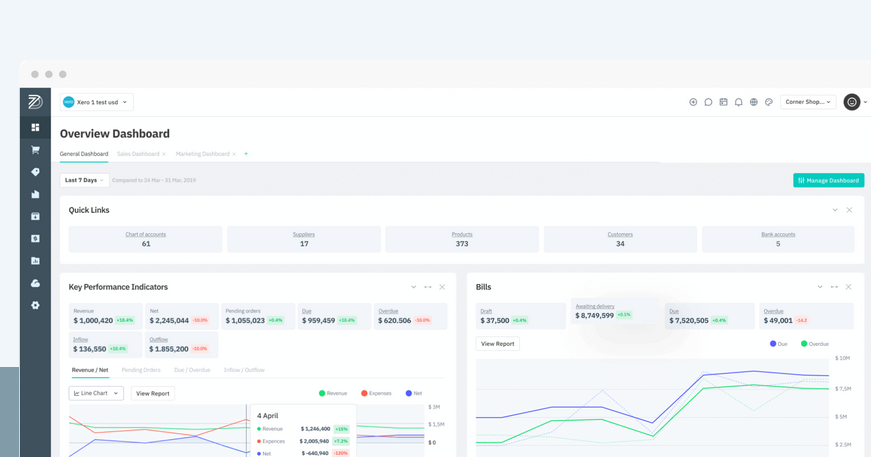

DEAR Systems

DEAR Systems is a cloud-based inventory management software for manufacturing businesses. It offers features such as purchasing, sales, warehouse management, and production management.

Pros: DEAR Systems provides comprehensive inventory management capabilities, integrates seamlessly with various accounting and e-commerce platforms, offers advanced reporting and analytics tools, and provides scalability to accommodate business growth.

Cons: The user interface may feel overwhelming for some users, and the software may require some time for setup and training.

Best for: DEAR Systems is suitable for small to mid-sized manufacturing businesses looking for a cloud-based solution that can streamline their inventory management processes and integrate with their existing software ecosystem.

Why it’s good: DEAR Systems stands out for its robust inventory management features, seamless integration with accounting and e-commerce platforms, and scalability to support business growth.

Infor CloudSuite Industrial (SyteLine)

Infor CloudSuite Industrial, formerly known as SyteLine, is an inventory management software for manufacturing businesses. It offers features such as production scheduling, supply chain management, and shop floor control.

Pros: Infor CloudSuite Industrial provides comprehensive inventory management and production planning capabilities, integrates seamlessly with other Infor products, offers industry-specific solutions for various manufacturing sectors, and provides scalability to meet the needs of growing businesses.

Cons: The implementation process can be complex and time-consuming, and the software may require customization to fit specific business requirements.

Best for: Infor CloudSuite Industrial is best suited for mid-sized to large manufacturing businesses looking for an integrated solution that can manage their entire manufacturing process from planning to execution.

Why it’s good: Infor CloudSuite Industrial stands out for its extensive features tailored for manufacturing businesses, seamless integration with other Infor products, and scalability to support business growth.

Manufacturing operations management software

IQMS Manufacturing ERP

IQMS Manufacturing ERP is a comprehensive manufacturing operations management software that offers features such as production scheduling, inventory management, quality control, and supply chain management.

Pros: IQMS Manufacturing ERP provides end-to-end visibility into manufacturing operations, integrates seamlessly with other business systems, offers real-time analytics and reporting, and provides scalability to accommodate business growth.

Cons: The software may have a steep learning curve for new users, and the implementation process can be time-consuming.

Best for: IQMS Manufacturing ERP is ideal for mid-sized to large manufacturing businesses looking for a comprehensive solution to manage their manufacturing operations, from planning to execution.

Why it’s good: IQMS Manufacturing ERP stands out for its extensive features tailored for manufacturing operations, seamless integration with other business systems, and scalability to support business growth.

FactoryLogix MES

FactoryLogix MES is a modular manufacturing operations management software that offers features such as production planning, scheduling, quality management, and shop floor control.

Pros: FactoryLogix MES provides real-time visibility into manufacturing processes, offers advanced quality management tools, integrates seamlessly with other business systems, and provides flexibility to customize workflows based on specific requirements.

Cons: The cost of implementation and customization can be high, and the software may require extensive training for users to utilize its full capabilities effectively.

Best for: FactoryLogix MES is best suited for mid-sized to large manufacturing businesses looking for a modular solution to manage their manufacturing operations with a focus on quality management.

Why it’s good: FactoryLogix MES is highly regarded for its real-time visibility into manufacturing processes, advanced quality management capabilities, and flexibility to customize workflows to fit specific business needs.

Epicor Mattec MES

Epicor Mattec MES is a manufacturing operations management software that offers features such as real-time production monitoring, quality management, and machine data collection.

Pros: Epicor Mattec MES provides real-time insights into production performance, offers advanced quality management tools, integrates seamlessly with other Epicor ERP solutions, and provides scalability to accommodate business growth.

Cons: The software may have limited integration capabilities with third-party systems, and the user interface may feel outdated for some users.

Best for: Epicor Mattec MES is suitable for mid-sized manufacturing businesses looking for a comprehensive solution to monitor and improve production efficiency and quality.

Why it’s good: Epicor Mattec MES is highly regarded for its real-time production monitoring capabilities, advanced quality management tools, and seamless integration with other Epicor ERP solutions.

SAP Manufacturing Execution

SAP Manufacturing Execution is a comprehensive manufacturing operations management software that offers features such as production planning, scheduling, execution, and quality management.

Pros: SAP Manufacturing Execution provides end-to-end visibility and control over manufacturing operations, integrates seamlessly with other SAP solutions, offers advanced analytics and reporting tools, and provides scalability to support business growth.

Cons: The cost of implementation and licensing can be high, and the software may require extensive customization to fit specific business requirements.

Best for: SAP Manufacturing Execution is best suited for large manufacturing businesses looking for an enterprise-level solution to manage their manufacturing operations with integration into their existing SAP ecosystem.

Why it’s good: SAP Manufacturing Execution stands out for its comprehensive features, seamless integration with other SAP solutions, and scalability to support the needs of large manufacturing businesses.

Manufacturing process management software

Apriso Manufacturing Execution System

Apriso Manufacturing Execution System (MES) is a comprehensive manufacturing process management software that offers features such as production scheduling, quality management, inventory tracking, and real-time performance monitoring.

Pros: Apriso MES provides end-to-end visibility and control over manufacturing processes, integrates seamlessly with other business systems, offers advanced analytics and reporting tools, and provides scalability to accommodate business growth.

Cons: The software may have a steep learning curve for new users, and the implementation process can be complex and time-consuming.

Best for: Apriso MES is ideal for mid-sized to large manufacturing businesses looking for a comprehensive solution to manage their manufacturing processes with a focus on real-time performance monitoring and quality management.

Why it’s good: Apriso MES stands out for its comprehensive features tailored for manufacturing process management, seamless integration with other business systems, and scalability to support business growth.

Siemens Opcenter Execution Manufacturing

Siemens Opcenter Execution Manufacturing, formerly known as Camstar, is a manufacturing process management software that offers features such as production control, quality management, and regulatory compliance.

Pros: Siemens Opcenter Execution Manufacturing provides real-time visibility into production processes, offers advanced quality management tools, integrates seamlessly with other Siemens PLM software, and provides scalability to accommodate business growth.

Cons: The software may have a complex user interface, and the implementation process can be challenging for some organizations.

Best for: Siemens Opcenter Execution Manufacturing is best suited for mid-sized to large manufacturing businesses looking for a comprehensive solution to manage their manufacturing processes with a focus on quality management and regulatory compliance.

Why it’s good: Siemens Opcenter Execution Manufacturing is highly regarded for its real-time visibility into production processes, advanced quality management capabilities, and seamless integration with other Siemens PLM software.

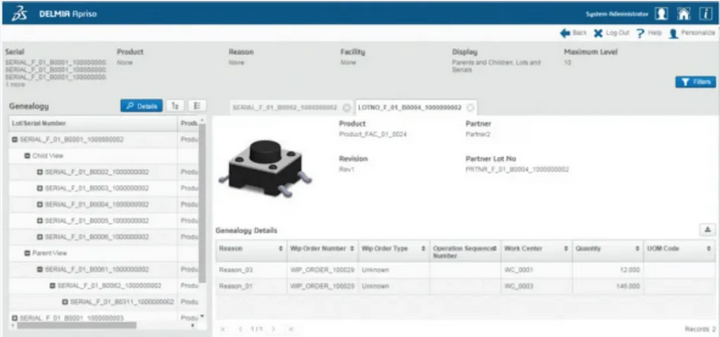

Lighthouse MES

Lighthouse MES is a manufacturing process management software that offers features such as production planning, execution, and quality management.

Pros: Lighthouse MES provides real-time visibility into production processes, offers advanced quality management tools, integrates seamlessly with other business systems, and provides flexibility to customize workflows based on specific requirements.

Cons: The software may lack some advanced features compared to other solutions, and the user interface may feel outdated for some users.

Best for: Lighthouse MES is suitable for mid-sized manufacturing businesses looking for a comprehensive solution to manage their manufacturing processes with a focus on real-time visibility and quality management.

Why it’s good: Lighthouse MES is highly regarded for its real-time visibility into production processes, advanced quality management capabilities, and flexibility to customize workflows to fit specific business needs.

Manufacturing workflow management software:

Process Street

Process Street is a comprehensive workflow management software that offers features such as process documentation, workflow automation, task management, and collaboration tools.

Pros: Process Street provides a user-friendly interface for creating and managing workflows, offers customizable templates for various manufacturing processes, integrates seamlessly with other business systems, and provides real-time analytics and reporting.

Cons: The pricing can be relatively high for certain usage levels.

Best for: Process Street is ideal for manufacturing businesses of all sizes looking for a flexible and customizable solution to streamline their workflow management processes.

Why it’s good: Process Street stands out for its user-friendly interface, customizable templates, seamless integration with other business systems, and robust workflow management capabilities.

MasterControl Manufacturing Excellence

MasterControl Manufacturing Excellence is a manufacturing workflow management software that offers features such as document control, change management, training management, and compliance management.

Pros: MasterControl Manufacturing Excellence provides end-to-end visibility and control over manufacturing processes, offers advanced compliance management tools, integrates seamlessly with other business systems, and provides scalability to accommodate business growth.

Cons: The cost of implementation and licensing can be high, and the software may require extensive customization to fit specific business requirements.

Best for: MasterControl Manufacturing Excellence is best suited for mid-sized to large manufacturing businesses looking for an enterprise-level solution to manage their manufacturing workflows with a focus on compliance and quality management.

Why it’s good: MasterControl Manufacturing Excellence is highly regarded for its comprehensive features, advanced compliance management capabilities, seamless integration with other business systems, and scalability to support the needs of large manufacturing businesses.

TrackVia

TrackVia is a cloud-based manufacturing workflow management software that offers features such as process automation, task management, reporting, and analytics.

Pros: TrackVia provides a user-friendly interface for building and managing workflows, offers customizable templates for various manufacturing processes, integrates seamlessly with other business systems, and provides real-time analytics and reporting.

Cons: The software may lack some advanced features compared to other solutions, and the pricing can be relatively high for certain usage levels.

Best for: TrackVia is ideal for manufacturing businesses of all sizes looking for a flexible and customizable solution to streamline their workflow management processes.

Why it’s good: TrackVia stands out for its user-friendly interface, customizable templates, seamless integration with other business systems, and robust workflow management capabilities.

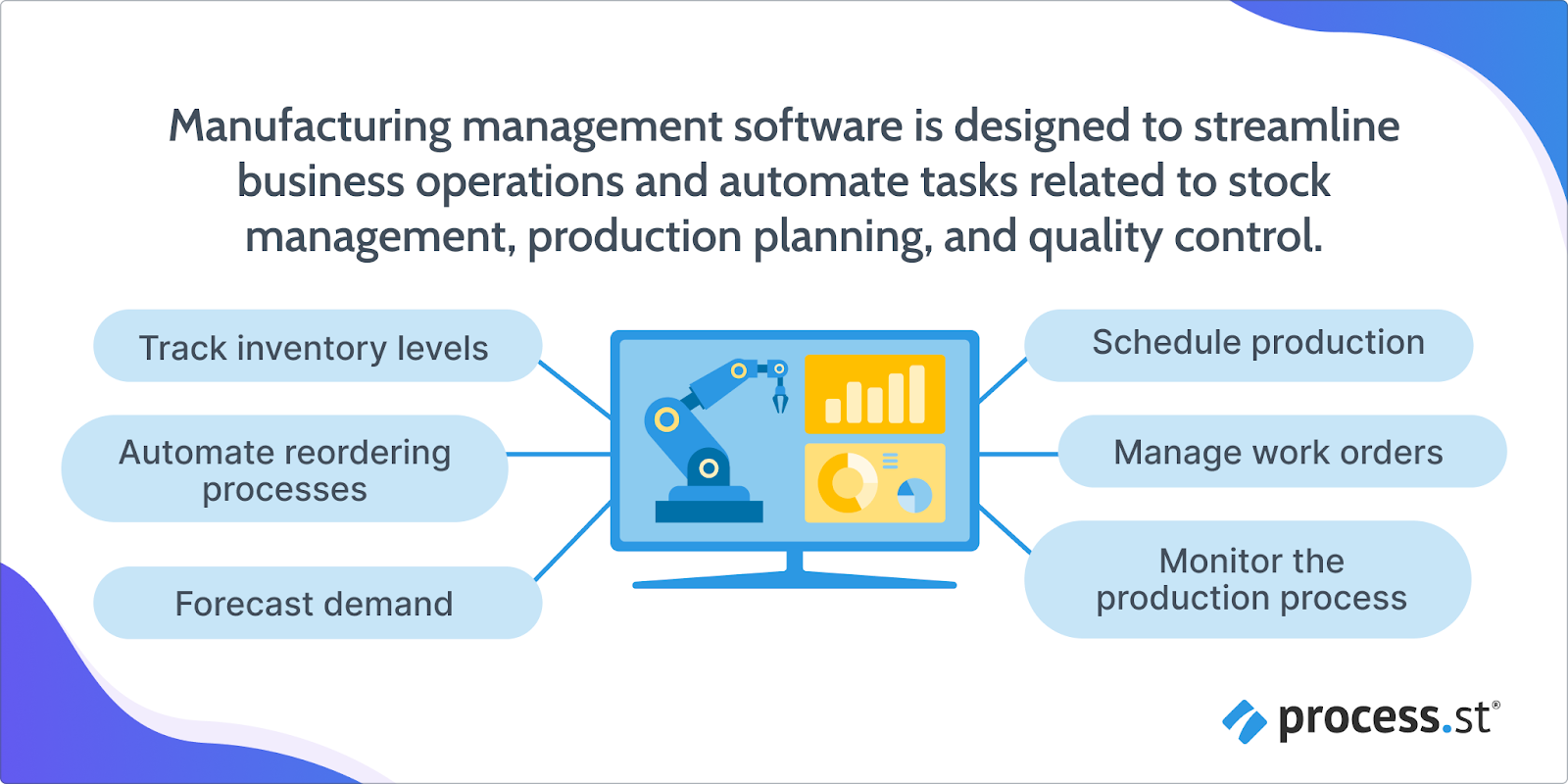

What is manufacturing management software?

Manufacturing management software is a solution designed to streamline business operations and automate tasks related to stock management, production planning, and quality control.

It is particularly well-suited for small-to-medium-size manufacturing businesses seeking to improve their efficiency and productivity.

The software can:

- Track inventory levels

- Automate reordering processes

- Forecast demand

- Schedule production

- Manage work orders

- Monitor the production process

Pros and cons of using manufacturing management software

The main benefits of utilizing this type of software are:

- Increased operational efficiency

- Better inventory management

- Reduced production costs

- Improved decision-making through real-time data and analytics

However, potential disadvantages may include:

- Initial cost of implementation

- Need for employee training

- Potential downtime during the transition period

Key features to look for in manufacturing software

When choosing manufacturing software, ensure that it has the following key features:

- Serial number tracking for product recalls

- Real-time production monitoring

- Integration with supply chain management

- Quality management tools to ensure compliance with industry standards and regulations

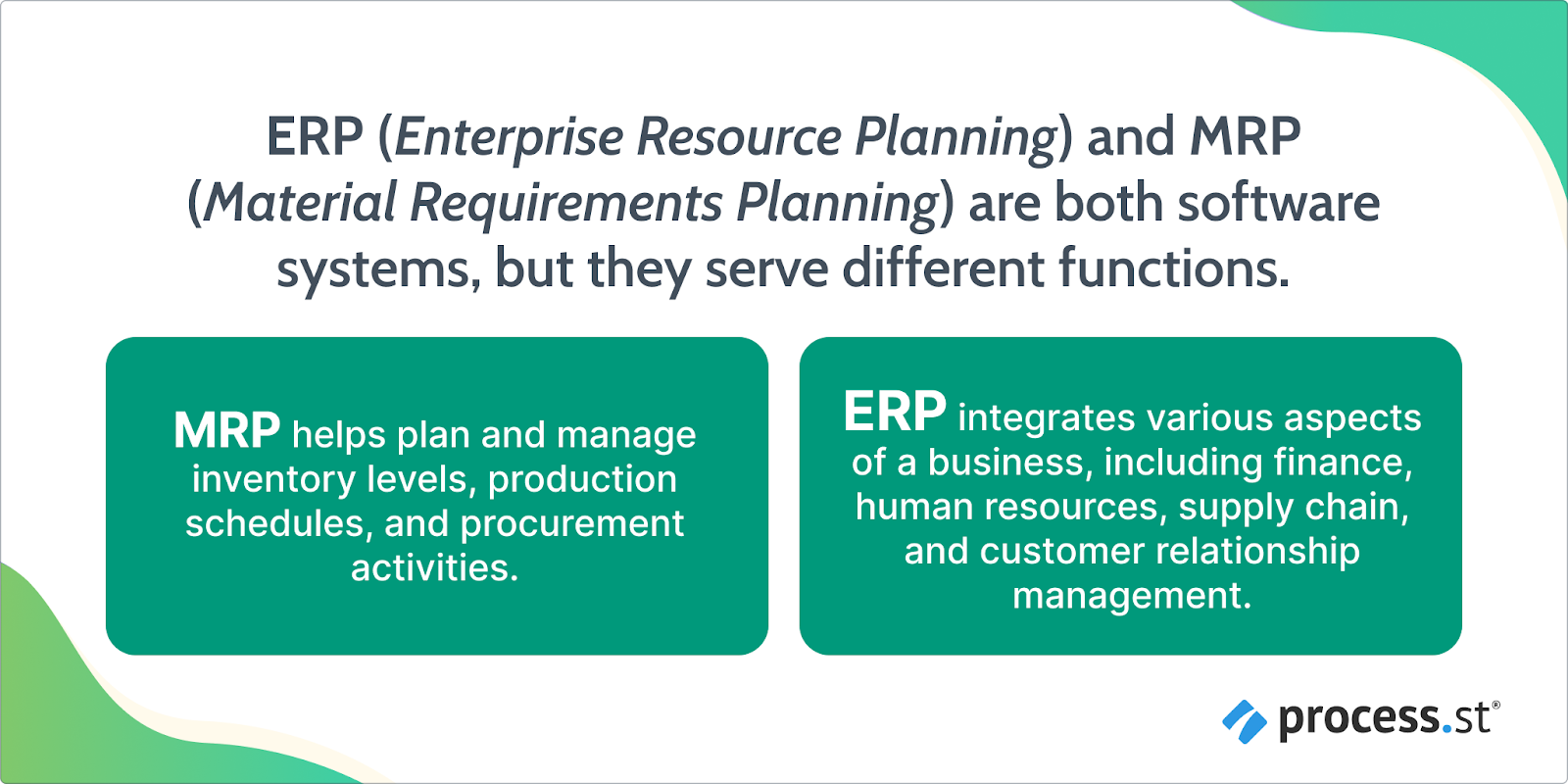

What’s the difference between ERP and MRP?

ERP (Enterprise Resource Planning) and MRP (Material Requirements Planning) are both software systems used by businesses to streamline their operations, but they serve different functions and target different users.

MRP

MRP is focused on the management of materials and production planning, making it ideal for manufacturing and production companies.

It helps plan and manage inventory levels, production schedules, and procurement activities.

ERP

ERP is a comprehensive system that integrates various aspects of a business, including finance, human resources, supply chain, and customer relationship management.

It is designed for a wide range of industries and can be used by different departments within an organization.

While MRP is more focused on specific production-related tasks, ERP has a broader scope and can handle a variety of business processes.

ERP is often seen as the next step after MRP, as it not only manages materials but also incorporates other crucial aspects of a company’s operations.

What are the 5 types of software used in manufacturing?

The main types of software used in manufacturing are:

1. Product Lifecycle Management (PLM) software

This type of software helps in managing the entire lifecycle of a product, from ideation to disposal. PLM software enables collaboration, version control, and data management. It is well-suited for industries that focus on new product development and innovation.

2. Enterprise Resource Planning (ERP) software

ERP software integrates various business processes such as inventory management, supply chain, and production planning. It offers real-time visibility and helps in streamlining operations. It is commonly used in industries with complex supply chains and large-scale manufacturing operations.

3. Computer-Aided Design (CAD) software

CAD software is used for creating, modifying, and optimizing designs for products and parts. It enables engineers and designers to visualize, test, and improve their designs. It is essential for industries that rely on precision engineering and customized products.

4. Manufacturing Execution System (MES) software

MES software helps monitor and control production processes on the shop floor. It provides real-time data, quality control, and performance analysis. This software is crucial for industries with high-volume production and strict quality standards.

5. Customer Relationship Management (CRM) software

CRM software is used to manage interactions and relationships with customers. It helps in sales, marketing, and customer support. It is beneficial for industries that focus on customer-centric manufacturing and after-sales service.

Each type of software has its own advantages and disadvantages, but they are tailored to specific industries and businesses within the manufacturing sector.

Do I need manufacturing management software?

If you are a small-to-medium-size manufacturing business, there are key factors to consider when determining if you need manufacturing management software.

Automation

Firstly, if your business operations require streamlining and automating, this software can help you achieve efficiency and reduce manual errors.

Inventory optimization

If you struggle with optimizing inventory management and production planning, manufacturing management software can provide real-time data and insights to help you make informed decisions.

Collaboration and insights

Lastly, if you are seeking actionable insights and collaboration across different departments, this software can provide you with the necessary tools to streamline communication and cooperation.

Investing in manufacturing management software can lead to numerous benefits for your business. For example, it can:

- Help you streamline and automate your business operations

- Optimize inventory management

- Manage production planning

- Provide insights and collaboration features

Overall, it’s safe to say that having the right tools to manage and improve your operations is key to success.