We always seem to be caught up in a never-ending mission to make our businesses better.

We always seem to be caught up in a never-ending mission to make our businesses better.

You have to ride out crises, fight through external problems, and still improve your performance week on week, quarter on quarter, year on year.

So how do we approach this improvement to get the most from it?

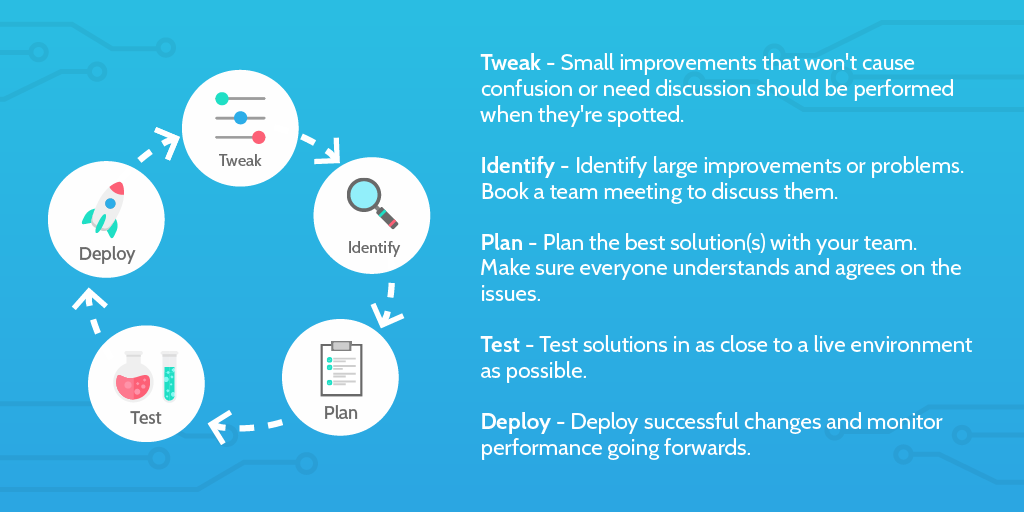

The key is about making improvement part of the daily process.

This approach falls under the umbrella of continuous improvement; what Toyota call Kaizen.

This is the art of taking a million steps forward. Compounding every success and safeguarding against every failure.

In this Process Street article, we’ll look at:

- Why Kaizen is important

- What are the other Toyota Production System concepts?

- Things to consider when implementing Kaizen.

- How Samsung use Kaizen selectively to optimize production

Why Kaizen is important

Kaizen is a big deal because broadly speaking it works.

As an ethos, it is always going to point you in the right direction, and when used in conjunction with the other key lean principles of the Toyota Production System you know you’re using tried and tested methods.

The Toyota Production System is the set of operational practices which allowed Toyota to surge into pole position as the largest car manufacturer in the world.

Kaizen is one of the real key elements of this approach so deserves our time.

Everybody’s doin’ it

It’s not just Toyota who are employing Kaizen in its business operations. Many of the world’s largest and most successful companies, particularly in manufacturing, have been employing Kaizen to boost their efficiency and output.

We even use it at Process Street!

The kinds of operations which benefit most from a strict implementation of Kaizen are those with highly specific and standardized processes and procedures. The standardized nature of those operations allow for small iterative potential improvements to be found. Once found, they can then be acted upon, and we end up following the Kaizen approach.

The kind of industries which benefit most from Kaizen might be:

- Manufacturing

- Finance

- Operations

I’m taking broad brushstrokes here, but it isn’t always this cut and dry. As explained in an article in the Harvard Business Review:

In contrast, people in sales and marketing, which emphasize relationships and innovation, are less likely to embrace it readily. Nevertheless, some companies have applied improvement methods for innovation and growth with some success.

The article goes on to pick a few examples of unconventional areas, industries, or companies where Kaizen has been really effectively or famously employed.

DuPont, for example, created a sales and marketing process improvement methodology called “Top Line Growth” to boost revenue.

Pixar has adapted continuous improvement techniques from Toyota to review and assure the quality of its films as they are developed.

In an article on the Harvard Business School website, some reasons are suggested for how Pixar’s use of Kaizen impacts on the performance of the company:

The operating model also supports the business model and decreases the risk of a very expensive film failure by subjecting the work in process to constant quality control checks. High levels of cooperation and sharing throughout the production process allows for errors in storyline, dialogue, or visual effects to be caught early and often — before the process is too far along for these problems to be fixed. Though this increases the cycle time of the process (often only 2 seconds of a film is worked on each day!), Pixar’s box office performance has shown that the value gained from this process in quality and creativity added has definitely paid off.

The article cites a further Harvard Business Review article about how Pixar fosters collective creativity and a wonderful profile in the New Yorker about the company’s internal day to day operations.

We could give you a million case studies where Kaizen has worked effectively within a traditional factory setting, but the fact that it has also earned its stripes outside of its original environment speaks to its adaptability and strength.

What is Kaizen?

We’ve managed to get this far without even really touching on what Kaizen is, other than promoting continual improvement.

Well, you’ll be alarmed to hear that this is pretty much an effective working definition of it.

Lean Six Sigma Definition provide the following for us:

From the Japanese words “kai-” which means “change” and “-zen” which means “good.” The popular meaning from Toyota is “continuous improvement” or “small incremental improvements” of all areas of a company, not just manufacturing.

Expanding on that initial paragraph with:

Kaizen means all personnel are expected to stop their work when they encounter any abnormality and, along with their supervisor, suggest an improvement to resolve the abnormality.

It also talks about a slight sub-concept called a Kaizen burst, which is where an incremental change isn’t sufficient to fix the problem and a more radical process improvement method is required.

The key takeaway from this definition is the idea of incremental improvements.

This idea has a couple of roots which tie in to other areas of the Toyota Production System:

- You don’t know what a process should look like when you begin.

- You don’t want to stop production for radical process changes all the time.

- Once the main flow of a process is established, improving the small details can have a cumulative effect.

So really we have three key theoretical things laid out there for us:

- The epistemology of a process. Processes evolve and are discovered as much as designed.

- Operations must be practical and achieve business goals.

- Small details are often causes of defects and problems. Removing them creates compounded benefits.

So, let’s give a fairly standard textbook-style example of Kaizen in practice.

How Kaizen reduced production costs by 25%

This example is the story of a meat tenderizer factory and is brought to us by Chen & Dugger in their paper A Kaizen Based Approach for Cellular Manufacturing System Design: A Case Study.

This example is the story of a meat tenderizer factory and is brought to us by Chen & Dugger in their paper A Kaizen Based Approach for Cellular Manufacturing System Design: A Case Study.

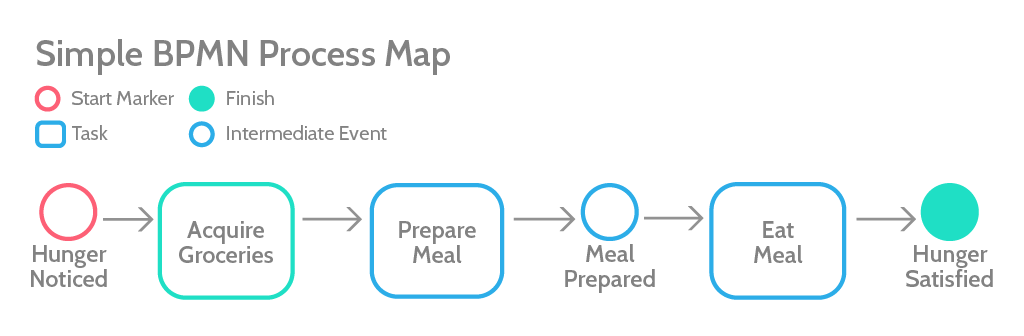

The factory in question utilized a Kaizen model for its teams to self-diagnose and treat process problems in the business operations. The problem is identified and the Kaizen approach kicks in!

The initial problem was that the meat tenderizers the factory produced were too expensive. It simply cost too much to manufacture them.

We’ll walk through the process of how the team turned the factory around.

Assemble workers around a problem

The company firstly assembled a team of skilled stakeholders to undertake the process improvement investigation:

In order to address this system design problem, a design engineer, a manufacturing engineer, a quality engineer, and two machining operators were invited to be team members in this Kaizen project.

The improvement team and other key stakeholders from both management and the shop floor met to discuss the existing process problems, business impact, and necessary baseline level of improvements needed.

After this initial brainstorm, the team defined some goals:

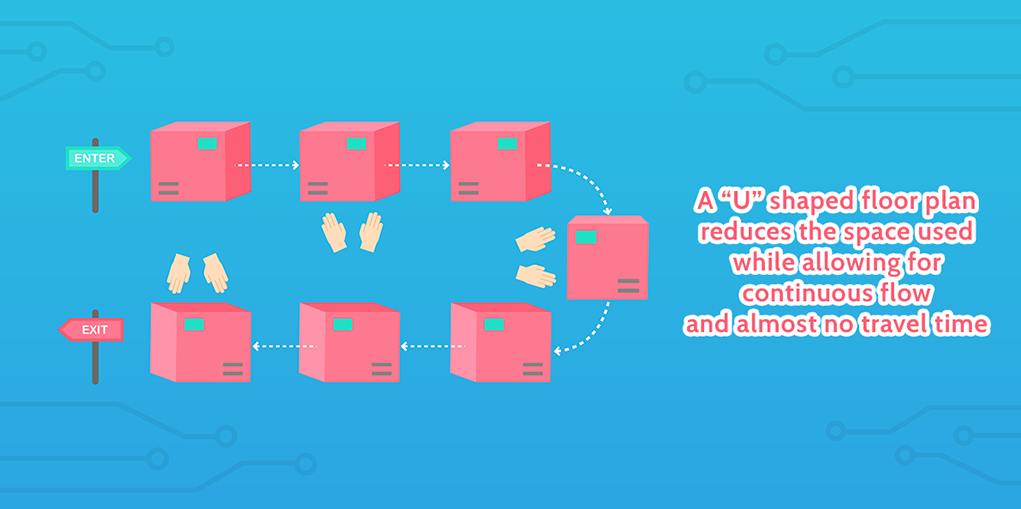

For this particular project, there were three goals: (a) reduce 25% of the unit cost, (b) design a cellular manufacturing system, and (c) reduce floor space by 15%.

With these goals in mind, the team assessed the existing process. Four different parts needed to be machined and then assembled, then packaged. The different parts needed producing in time for assembly without delays and the assembly needed to be sped up.

Understand the existing process and map alternatives

This process mapping was done with measurements of how long each part takes to create, how far each part needs to travel, and how assembly is managed.

This process mapping was done with measurements of how long each part takes to create, how far each part needs to travel, and how assembly is managed.

Chen & Duggan describe the next step:

Once everyone on the team understands the current method, a brainstorming phase begins in order to accumulate ideas determining seven new processes to be evaluated. No ideas are too bizarre, ranging from doing nothing at all to viewing various ways to completely redesign the process. The number of new processes changes depending on the project, but seven is the number typically used because it creates a high degree of stimulation during the limited time allotted for the brainstorming phase.

These 7 alternative process ideas were then mapped and displayed together on a visual chart.

This allows all the members of the team to understand each process proposal and to evaluate some of the strengths or weaknesses of each against the others.

Once the suggestions are all understood and ready to be analyzed, the evaluation stage can begin. The team decided first the metrics which they would judge each process on. The metrics given were as follows:

The decision was made to evaluate this project based on the following criteria: (a) flexibility: with two subcriteria: simplicity and ease of repetition; (b) cost: with five subcriteria: capital investment, labor costs, tooling costs, known technology, and required maintenance costs; and (c) safety: with seven subcriteria: safe, clean, ergonomic, of desired quality, required skills, defects per shift, and meets customer specifications.

After intense discussion and research, the final decisions need to be made.

Each member of the team was given the responsibility of providing a score for each proposed process on a scale of 1-5. From here, the results were tallied and the process options democratically selected. It is common to take the 3 top scoring options forward to simulation, but in this scenario there was one proposed process which stood out far above the rest on the balance of votes.

Test your improved process and measure the results

Once the new process had been chosen for testing, the team sets to work drawing up detailed instructions for each worker who will be involved in the process. This is then provided along with pictorial aids which show individual aspects of a process along with whole workflows. These visual aids are designed to provide clarity.

The theory was then to be put to the test.

The basic required infrastructure for the process to function was assembled and the team watched on as the workers followed the new process.

The results of this test:

The existing cycle time per assembly was 62 seconds. The new cycle time was about 28 seconds, which constitutes an approximate 44% reduction in cycle time. The existing assembly area consisting of workstations occupied 192 square feet. The proposed assembly area requires two cells, which use a space of 160 square feet. The new plan reduces the workspace by 37%. Quality to the consumer is 100% because the “make one check one pass one on” method provides 100% inspection, ensuring that no inferior-quality products are passed on to the consumer.

Kaizen speeds up decision making

One of the key takeaways worth expanding on lies in the conclusion of the report.

The daily trials and tribulations that upper management once confronted on their own are now solved by the workforce, increasing morale and allowing upper management to concentrate efforts on strategic planning.

The practice of Kaizen in this example is a culture of continually improving working environments held as a responsibility of everyone who is working within that environment.

This process improvement exercise gathered a small number of the workers together to rapidly tackle an identified problem. Once a solution had been found, it was implemented. The process was saved and optimized by the staff on the ground at the time it was needed.

It wasn’t a 6 month long task undertaken by a large consulting body. It was the on-the-ground workers who fixed their own process problems as a result of work practices centered around continuous improvement.

Next time a problem is discovered by that team, they’ll quickly do the same exercise again to improve the process and get back to work, more efficiently than ever.

How you can implement Kaizen in your business in 9 steps

If you wanted to take the same approach as the company in the study discussed above, then it’s a fairly simple process on the surface.

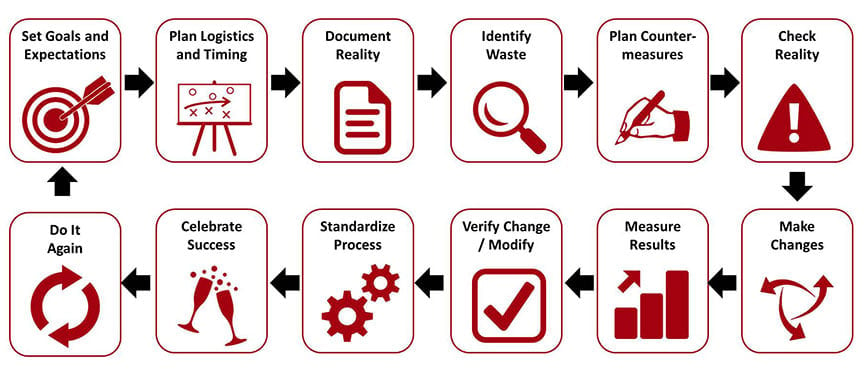

Everytime you think you’ve found a problem which needs fixing, you run this process:

- Identify the problem.

- Form a team.

- Gather information from internal and external customers, and determine goals for the project.

- Review the current situation or process.

- Brainstorm and consider seven possible alternatives.

- Decide the three best alternatives of the seven.

- Simulate and evaluate these alternatives before implementation.

- Present the idea and suggestions to managers.

- Physically implement the Kaizen results and take account of the effects.

A true Kaizen approach would be to have all the teams in your company performing this kind of evaluation and improvement autonomously on an ongoing basis.

That’s how you implement Kaizen.

What are the other Toyota Production System concepts?

Kaizen is at the core of the Toyota Production System but it isn’t the only concept employed in this school of thought.

The TPS is filled with what have come to be considered as lean manufacturing principles. These can act as guiding concepts to help you solve problems in your business, whether you’re a manufacturer, an online marketer, or have your own franchise restaurant.

Let’s quickly run through a selection of Toyota concepts. We’ll provide the concept, an outline, and a link off to another resource for a more detailed explanation.

Muda: How to identify waste

Muda is the Japanese word for waste and the Toyota system has a key emphasis on the removal of waste at each turn.

Muda is the Japanese word for waste and the Toyota system has a key emphasis on the removal of waste at each turn.

There are 7 main types of Muda:

- Waste of overproduction (largest waste)

- Waste of time on hand (waiting)

- Waste of transportation

- Waste of processing itself

- Waste of stock at hand

- Waste of movement

- Waste of making defective products

You can read more about Muda here: What is Muda? The 7 Wastes Every Lean Business Needs to Combat

Poka Yoke: How to mistake-proof your systems

A poka yoke is a really simple addition you might make to a process to stop mistakes from occurring. The poka yoke could function in one of 3 ways:

- The contact method: Come into contact with the product. Having a step in a production process where someone visually inspects a product is a good example.

- The fixed value method: Building a system which checks a process has been followed. If a step in the process has been missed then there is a higher chance of producing defects.

- The motion step method: Building a system which checks the process was followed in the correct order. This is also known as the sequence method and is subtly different to the fixed value method.

You can read more about poka yoke here: Are You Poka-Yoke Woke? Stop Mistakes With This Error Prevention Method (10 Examples)

Jidoka: How to automatically identify defects

Jidoka is about building in automated defect detection into your process. In this way, it’s similar to poka yoke but instead of it being an error prevention concept, it’s a defect detection process. Subtly different.

Toyota’s founder Sakichi Toyoda invented a textile loom which was capable of detecting when a thread had broken. This allowed the loom to stop itself and provide an alert for an operator.

Over the past 100 years, Jidoka has developed significantly and many advanced techniques have come to be used.

You can read more about Jidoka here: Jidoka: Why Automation Plus Intelligence Equals Best Results

One piece flow: How to reduce production time and waste

One piece flow is the idea that only one thing is being worked on at any given time at any given stage of the process.

One piece flow is the idea that only one thing is being worked on at any given time at any given stage of the process.

The goal is to have a smooth functioning system without backlogs or queues.

That means that there is a maximum of one item at any given stage of the process. Multiple items can be in the process as a whole, but nothing has to queue up and take up space from the moment it starts until the moment it’s complete.

The theory employs Little’s Law which works out how long an item spends within a system. It’s about producing what you need when you need it, and doing so in the most efficient manner.

You can read more about it here: How One Piece Flow Can Reduce Your Operations Time by 96%

Genchi Genbutsu: How to improve a process by embedding yourself into it

Genchi genbutsu roughly translates as “go see” and refers to the idea that you should go to where the process is occurring when you want to try to improve it.

Instead of simply making decisions on reported data or second hand information about the shop floor, you should visit and talk to people and investigate yourself.

It can even be applied to products. Toyota paid for one of their engineers to drive a Toyota Sienna around America for a year. The original Sienna wasn’t popular, so they sent an engineer to experience the product in its main market and to see how it performs. The engineer’s report recommended a host of technical changes and a whole new way of understanding how a minivan should work:

The parents and grandparents may own the minivan, but it’s the kids who rule it. It’s the kids who occupy the rear two-thirds of the vehicle, and are the most appreciative of their environment.

A minivan should be designed for the benefit of children. A new ethos behind the product. The new Sienna design proved to be a roaring success.

You can read more about genchi genbutsu here: Genchi Genbutsu: The Problem Solving Concept Which Drives Toyota Forward

Use continuous caution in how you implement Kaizen

Kaizen is great. But not every approach which worked for Toyota can or should be directly implanted into your business without a critical eye.

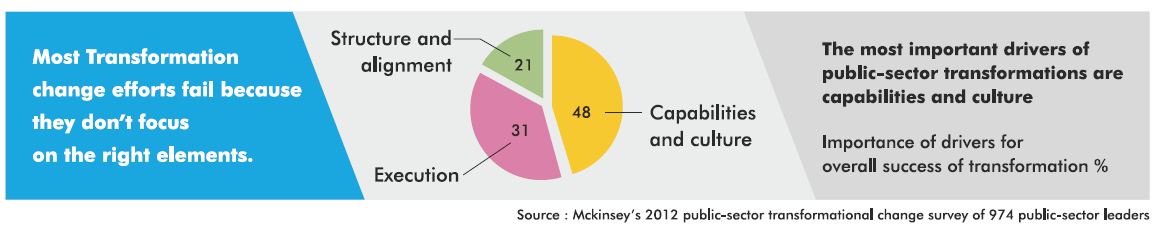

Ron Ashkenas, Partner Emeritus at Schaffer Consulting, writes for the Harvard Business Review on some challenges you might face when utilizing kaizen and makes a series of recommendations for managing its implementation.

Ashkenas credits the use of Japanese production techniques for the rise in Japanese manufacturing output and market dominance, and highlights the impact these methods had on American manufacturers too; Motorola developed the Six Sigma principles in this vein, for example.

However, he notes that Japanese industry has been struggling performance wise in recent years and its seeing much of its market dominance slip as competition rises from South Korea and China.

He also points out that US companies which used to be very focused around Six Sigma techniques, like DMAIC or DFSS, have begun to loosen their application of the methodologies.

Ashkenas gives us three considerations when implementing kaizen and continuous improvement into our businesses.

Use continuous improvement in the right places and in the right ways

One size of continuous improvement doesn’t fit all parts of the organization. The kind of rigor required in a manufacturing environment may be unnecessary, or even destructive, in a research or design shop. Sure it’s important to inject discipline into product and service development, but not so much that it discourages creativity.

Just like you might have a tight structured process for a sales call but not for writing an article, you should use kaizen techniques where they are suited rather than shoehorning them in.

Should a process be improved or removed?

Too many continuous improvement projects focus so much on gaining efficiencies that they don’t challenge the basic assumptions of what’s being done.

An efficient process isn’t necessarily a good process. It may be that the company would function better if that process was removed and an alternative system used. Sometimes big change – disruption – is necessary.

How does it affect the behavior and culture of your team?

A data-driven mindset may encourage managers to ignore intuition or anomalous data that doesn’t fit preconceived notions. In other cases it causes managers to ask execution-oriented, cost-focused questions way too early, instead of percolating and exploring ideas through messy experimentation that can’t be justified through traditional metrics.

Innovation requires exploration and failure. Focusing too hard on the high performance of a process can inhibit the discovery of new ways to operate. It can also ignore intangible benefits or metrics which are harder to measure. If you need to prove yourself via data, you may opt for solutions which give you better data – and they might not be the ones which deliver better results.

It’s incredibly difficult to judge whether a content marketing strategy is successful until you’ve been doing it for a while. Content marketing is also something with cumulative benefits. If you have to prove yourself on data alone, it could be difficult to justify content marketing even if it’s the right option for the business.

Many of these concerns about being too rigid with production systems are not new. The importance of building a theory of your business or organization and testing everything against an abstracted notion of quality-in-the-eyes-of-the-customer is something which has been advocated by William Edwards Deming, in particular.

You can gain a deeper understanding of Deming and his thought here: How to Use The Deming Cycle for Continuous Quality Improvement

The Samsung Way: Merging traditional Japanese and US managerial practices

Ashkenas pointed out, one of the big winners in recent years has been South Korea, with Samsung being a flagship company for its rise.

While Japan and the US weathered the storm of the financial crash but failed to sprint out of the slump, China and South Korea went full Keynesian and spent their way out of crisis.

South Korea and China had different financial circumstances and debt-relationships to the US, Japan, and the UK, so it’s not for me to say which country made the better decision, but it has definitely paid off for South Korea.

This massive state investment allowed South Korean firms to take advantage of where market leaders were struggling and the knowledge of state support allowed them to invest heavily into R&D in particular. Recent Samsung success were aided by these external conditions, but the bedrock for them came earlier.

Samsung took an approach to its business where it wanted to combine Japanese production processes with US cultures of working. According to Dr. Jaeyong Song from an interview in Industry Week:

The most important factor in Samsung’s success was the New Management Initiative Chairman Lee proposed in 1993. At the time, Chairman Lee was very concerned about Samsung’s lack of competitiveness in the global marketplace.

… Chairman Lee was persistent enough to push forward massive change management throughout the 1990s, re-aligning every aspect of Samsung’s management system to its new quality-driven goal. In particular, Chairman Lee pushed Samsung to invest preemptively in R&D, brand marketing, and design capabilities for emerging digital products.

The outcomes of the New Management initiative were astounding. Since 2004, the operating profits of Samsung Electronics have consistently been higher than the sum of the annual operating profits of Japan’s five major electronics companies, including Sony and Panasonic.

So, it ended up being a great success. But what defines this new idea of The Samsung Way?

Song describes the Japanese approach as:

Generally, Japanese management is characterized by market share orientation, unrelated diversification, vertical integration, emphasis on manufacturing competitiveness and operational efficiency, strict organizational discipline, emphasis on employee loyalty, internal and seniority-based promotion and rewards, and participation of both workers and shareholders in management.

Whereas the American model is depicted as:

The American management style, on the other hand, emphasizes profits and revenue, focusing on relevant industries and frequently restructuring businesses and products. American companies also tend to outsource manufacturing or move abroad, finding the source of their core competencies in soft capabilities or intangible assets such as technological innovation, brand marketing capabilities, and design capabilities.

The Samsung incorporation of both has led to a model with these important factors:

- Vertical and horizontal diversification

- High emphasis on product quality

- Standardized workforce processes

- Regular restructuring efforts

- High emphasis on soft-capabilities like branding

- Performance based compensation

It’s a kind of pick and mix of approaches. Now, you might be wondering where kaizen comes into this. I’ll give you an example.

Samsung have plants in South Korea. The workers at these plants are highly trained and are skilled employees. In these plants we’ll see advanced production systems and the use of kaizen methodologies for fast-paced on-the-ground process improvement strategies.

However, Samsung – taking American influence – also have factories which are quasi-outsourced. In these factories, the tasks are simpler and the workers less specialized. In these environments there is less of an effort to employ kaizen techniques like the one demonstrated in our case study in this article. Instead, those factories use different methodologies.

The flexibility here demonstrates that kaizen is best when used in the right environments. The knowledge gained from process advancements in one factory can be supplanted into another factory which doesn’t have the internal skill set to discover it itself.

Samsung utilize kaizen in the right places at the right times. And they’re crushing it.

Use kaizen in your business to optimize your processes

So, the key conclusions to this are:

- Use kaizen where you have high skilled workers

- Use kaizen where you have highly standardized tasks

- Use kaizen to iterate through processes quickly

However, a few things to consider:

- Don’t let kaizen dictate strategy

- Don’t let kaizen mask unnecessary processes

- Don’t ignore other important related concepts and approaches

If it’s right for you, then give it a go!

Have you been a strict adherent of kaizen approaches in your business? What were your experiences? Let us know in the comments below!

Adam Henshall

I manage the content for Process Street and dabble in other projects inc language exchange app Idyoma on the side. Living in Sevilla in the south of Spain, my current hobby is learning Spanish! @adam_h_h on Twitter. Subscribe to my email newsletter here on Substack: Trust The Process. Or come join the conversation on Reddit at r/ProcessManagement.