How do you stand out against overwhelming competition? You need an edge; a value proposition isn’t enough on its own.

You need to make sure you’re out-competing the competition by keeping costs down and understanding the value you’re delivering to your customer. But how do you continuously improve your value offering while keeping costs down?

Enter the value chain.

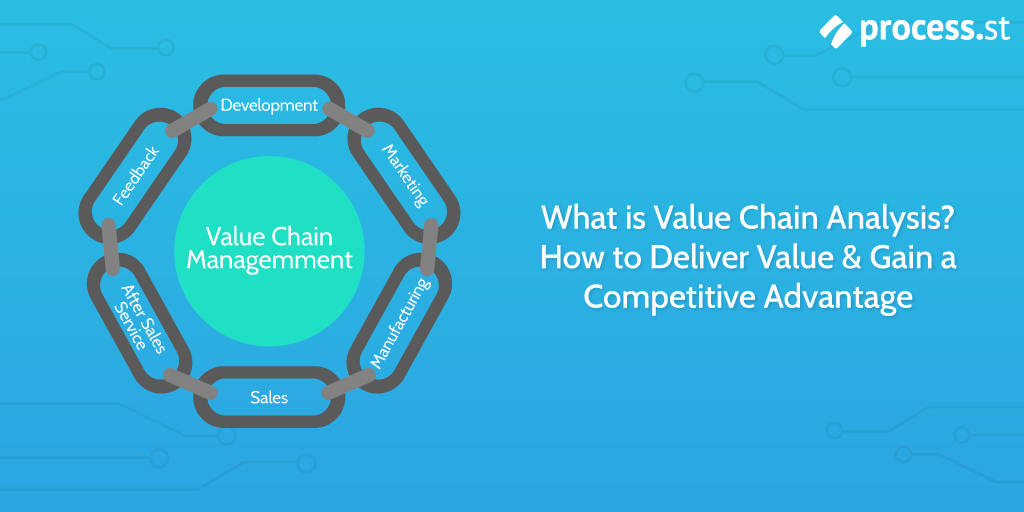

A value chain is a model of looking at all of your business processes and figuring out how to gain a competitive advantage by focusing on developing maximum value in your product or service, while keeping your profit margins in the green at the same time.

Originally proposed by Harvard’s Michael Porter in his 1998 book Competitive Advantage, there’s a lot of ground to cover. Where do you start? What’s the process? What kind of tools exist to make the value chain analysis easier?

Well, if you’re looking for a clear, concise introduction to Michael Porter’s Value Chain model, you’ve come to the right place. Read on for a breakdown of:

- What is a value chain?

- Michael Porter’s original value chain model

- Value chain analysis

- Benefits of value chain analysis

- Value chain analysis process

- Value chain vs supply chain

- Porter’s primary value chain components

- Porter’s secondary value chain components

- Bonus: Porter’s Five Forces

By the end of this article, you should have a firm grasp on the value chain model, with a better idea of how to apply it to your own business. We’ll also investigate how to integrate BPM software like Process Street into the value chain.

What is a value chain?

A value chain is a model for understanding a business by looking at the process for creating a product or service. From conception to distribution, at each stage of the process, the question is asked: How can we maximize value to gain a competitive advantage?

The term “value chain” refers to all of the business processes that combine to produce the desired product or service.

In order to build a value chain model of a business, you perform a value chain analysis. These techniques fall under the umbrella of value based management.

What is value-based management?

Value-based management (VMB) is a business process management approach centered around prioritizing and maximizing value creation.

You can also think of it as a management system that seeks to maximize shareholder value.

Value-based management involves everything to do with creating, analyzing, and sustaining value in a business.

Michael Porter’s Value Chain framework

Now that we’ve unpacked the simple idea of a value chain, it’s worth exploring where the term came from.

Originally, the concept of a value chain was introduced by Michael E. Porter in his book Competitive Advantage: Creating and Sustaining Superior Performance (Free Press, 1998).

“Competitive advantage cannot be understood by looking at a firm as a whole […] It stems from the many discrete activities a firm performs in designing, producing, marketing, delivering and supporting its product” – Michael Porter, Competitive Advantage: Creating and Sustaining Superior Performance

Simply put, his value chain framework highlighted the importance of maximizing value at each stage of an organization’s processes.

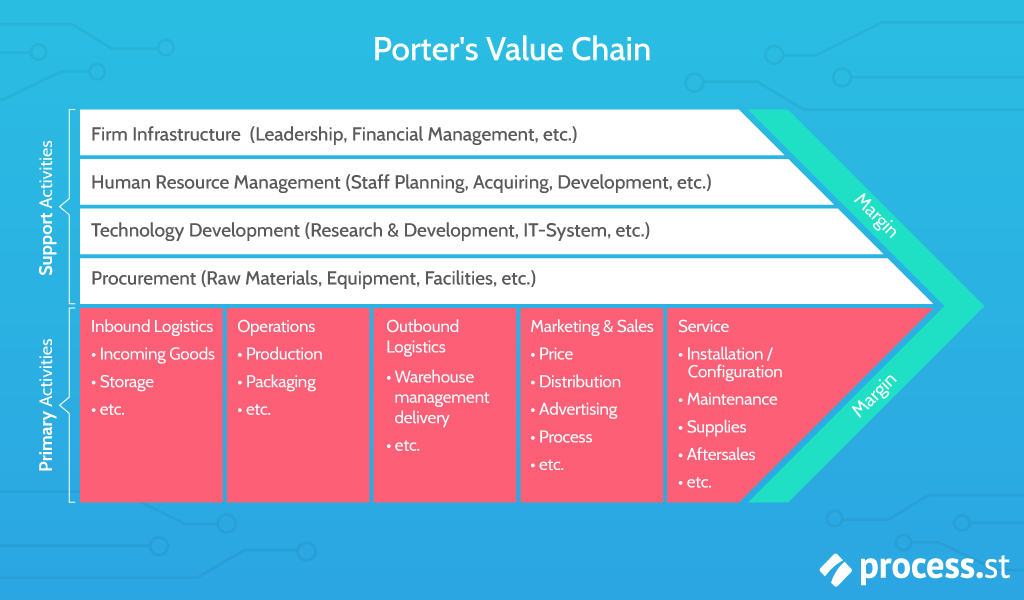

In the diagram below, you can see that Porter’s value chain is split into primary and support activities. Primary activities are the main “production” line processes, and support activities are things that quite literally support the primary production processes, like leadership, equipment, research and technology infrastructure, et cetera.

I’ll explore the primary and support activities more later on in the post.

What is the purpose of a value chain model?

The primary purpose of a value chain model is to understand how to gain a competitive advantage. It does this by looking at the production processes and figuring out how to deliver more value for the lowest cost.

Value chain analysis

Value chain analysis is the process of applying the value chain model to a business. You can use the results of a value chain analysis to understand the areas best targeted to improve the competitive advantage of your business.

Each step of production is analyzed in detail during a value chain analysis. So what exactly are we looking for during a value chain analysis?

The purpose, as stated above, is all about looking for ways to increase value and reduce costs.

There are a number of different strategies that can emerge as favorable as a result of a value chain analysis. The strategy you choose to gain a competitive advantage will depend on the findings of a value chain analysis.

So, you perform a value chain analysis to gain insight into which strategy is most appropriate (in terms of least cost, highest value) to gain a competitive advantage.

As such, it makes sense to think of these different competitive advantage strategies as “benefits” of a value chain analysis – the “benefit” being the insight into the most appropriate strategy.

In summary so far:

- Value chain model: A framework for understanding how to improve value and reduce costs to gain a competitive advantage.

- Value chain analysis: A process for analyzing a business in terms of the value chain model.

- Main goal: Increase production efficiency – more value for less cost.

- End goal: Creation of a competitive advantage.

- Components: Five primary activities, four support activities.

Benefits of a value chain analysis

Let’s look at some of the different strategies for gaining a competitive advantage that performing a value chain analysis will help you benefit from.

Porter’s generic strategies specify three main approaches that can pave the way to a competitive advantage:

- Cost leadership

- Differentiation

- Focus

Cost leadership

This involves providing your product or service for the lowest possible cost in a given market.

Competitive advantage is secured when consumers choose your offering over other competition on the basis of it being the lowest cost against a healthy balance of their perceived value.

Cost leadership involves targeting cost-conscious customers, and as such the value chain approach will involve seeking ways to essentially reduce differentiation by using standardized parts during production, simplified and economic processes involving less expertise, solving simple and common problems and not seeking to offer any truly unique value.

There are three main ways to achieve cost leadership:

- High asset utilization: Maximizing the efficiency between inputs and outputs. In manufacturing, this means producing as many units of output based on resource input. In services, it will mean maximizing the turnaround time of rooms in a hotel or tables in a restaurant.

- Low production/operation costs: Money is saved by offering highly standardized products that have little to no market differentiation, with the price point being the primary appeal. Cost reduction is sought at all levels of the business, by methods such as low wages, outsourcing, minimal spending on marketing and advertising, low rental agreements, and bulk-purchasing production materials.

- Utilizing value chain analysis: To regulate the entire scope of business processes for maximum cost-to-value relationship.

Cost leadership examples: McDonald’s, Megabus, Best Buy, Walmart, RyanAir

Differentiation

A differentiation strategy involves offering a unique or highly specialized product or service.

The core idea is using some kind of differentiation to set your product or service apart from the competition, and in preserving the perceived value of the product alongside this differentiation, succeed in gaining market share by offering a unique value proposition that is difficult to imitate.

In contrast to cost leadership, differentiation strategies often call for a higher price point for the product or service, due to both increased production costs as well as manufactured value as part of the differentiation strategy.

Differentiation requires the business to dedicate a large amount of time and resources into research and development of the offering. This means differentiation strategies are typically best suited for larger organizations with more resources to invest in the development of a viable differentiated product.

Goal of cost leadership: Reduce costs to improve margins

Goal of differentiation: Differentiate to improve margins

Cost leadership and differentiation are two different approaches, and it’s best to focus your efforts on a single strategy.

Differentiation examples: Whole Foods, Apple, Starbucks

Focus

There is a third category of Porter’s generic strategies for competitive advantage: Focus.

Focus is offering a specialized service in a niche market; think of it as applying the cost leadership or differentiation strategies in a niche market.

Porter split “focus” into two approaches:

- Cost focus

- Differentiation focus

The starting point is to concentrate on a particular niche market. That’s the “focus” part. But Porter argued you need something more to make sure you don’t risk competing against big companies that can afford to out-value you in your niche.

This “something more” is either reducing costs (via a cost leadership approach) or differentiating your product (via a differentiation approach).

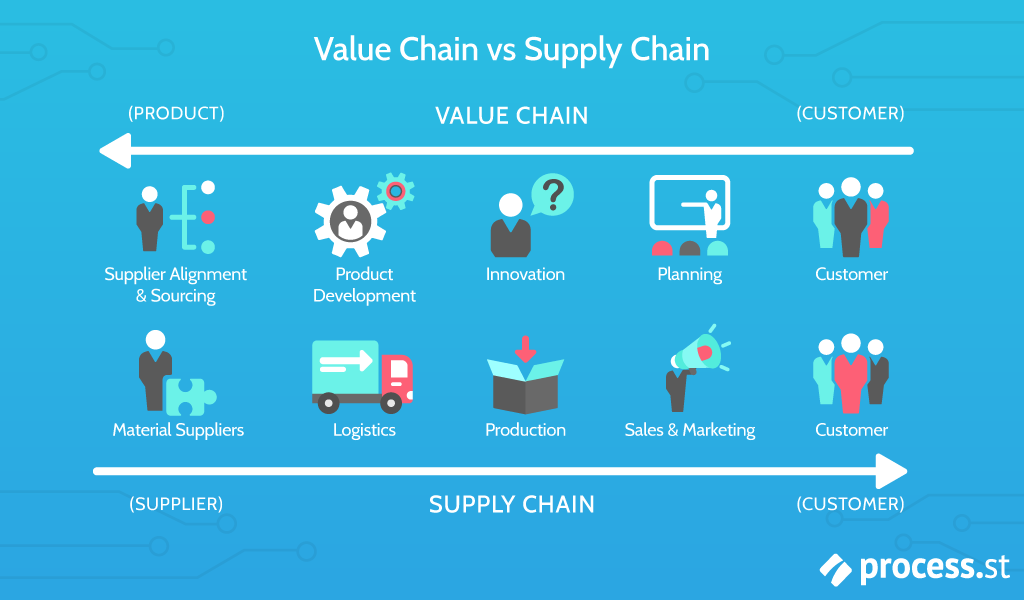

Value chain vs supply chain

“Value chain” often gets mentioned alongside “supply chain”. They are related, but very different concepts.

“Value chain” often gets mentioned alongside “supply chain”. They are related, but very different concepts.

To clear up some confusion:

Supply chain: Starting with the material supplier, and ending with the product or service delivered to the customer. This incorporates all activities from sourcing raw materials, logistics production, sales, marketing, and final delivery.

Value chain: Starting with the needs of the customer, a strategy is developed to provide maximum value for minimum cost, to gain a competitive advantage.

Porter’s value chain components: Primary activities

Michael Porter defined two categories of business processes in the value chain:

- Primary activities

- Support activities

Primary activities consist of five components that all contribute to adding value to achieve a competitive advantage:

- Inbound logistics

- Operations

- Outbound logistics

- Marketing and sales

- Service

It’s worth noting that, like Porter’s generic strategies, specific activities in each of the primary and secondary categories will be different depending on the industry they are applied to.

Inbound logistics

Everything relating to the company’s inputs (raw materials), and how they are taken care of.

This involves sourcing and receiving incoming goods, the economics of storing and managing inventory (warehousing, etc.) and all communication with external companies like suppliers.

Example: How Starbucks selects and sources high-quality coffee beans.

Operations

Processes for turning the raw materials into the final product or service.

Factory processes take center stage here: Machining, assembly, equipment testing and maintenance, packaging, and all facility operations.

Example: How Starbucks produces and packages the high-quality coffee beans they sell in-store.

Outbound logistics

Everything involved with getting that final product in front of a consumer.

Depending on the company, storage of products may be a factor here, or the product may be shipped immediately.

Example: Logistics involved with transporting Starbucks coffee beans (the whole bean product) to Starbucks stores across the country.

Marketing and sales

Making sure the customer knows the product exists, and making sure they want to buy it.

Advertising, promotional campaigns, pricing plans and product tiers are all part of this.

Example: Starbucks’ brand image, and the reputation they have cultivated as a premium coffee product and “second-home” shared space.

Service

Value isn’t intrinsic to the product; there must be a continuous effort to preserve and enhance the value offering of a product, even after (and sometimes before) it has been sold.

Customer service, feedback channels, repairs, refunds, and exchange programs are all relevant here.

Example: Starbucks is known for its high-quality and personalized customer service experience (i.e. writing your name on the cup).

Porter’s value chain components: Support activities

Primary activities form the backbone of the value chain – the support activities are there to make the primary activities more efficient.

There are four support activities:

- Infrastructure

- Procurement

- Human resources

- Research and development

Ideally, when you improve the efficiency of any one of these four support activities, the efficiency of at least one of the five primary activities should be improved as well.

You can typically think of the support activities as overhead costs on an income statement.

Infrastructure

This refers to the processes and procedures (the systems) in place for the management of a firm’s top-level business decisions. Everything from general strategic planning, finances, legal, compliance, and quality control.

Infrastructure is the underlying foundation of the entire value chain, not just individual activities. In coordinating business decisions and effectively managing resources, strategic infrastructure is one of the most valuable avenues to gain a competitive advantage.

Procurement

Everything relating to how resources and raw materials for a product’s creation are sourced, and suppliers found.

The goal of procurement as a support activity is to locate the highest quality supplies for the lowest cost possible.

Another way of thinking about procurement is the purchasing of inputs for the actual value chain (not the purchased raw materials themselves).

Management of human resources

Human resources management (HRM) is all activity involved in recruiting, hiring, compensation, firing, training, and development of new staff.

HRM impacts competitive advantage by determining the skill level of different employees against the cost of hiring and training them.

Depending on the industry, HRM may play a huge role – any company providing face-to-face services, or an offering involving a high level of skill or technical knowledge will benefit from the optimization of HRM to prioritize training and recruiting exceptional talent to gain a competitive advantage.

Research and development

Also known as “technology”, the R&D support activity is the design and development of manufacturing processes, including automation and optimization efforts.

Focusing on technological development can help a business discover new ways to innovate, and as such may help in differentiating the product, or even lowering production costs by improving production efficiency.

R&D efforts typically focus on product and process improvements, for example how you might use a BPM software like Process Street to:

- Upgrade from a paper office to a digital process suite

- Automate manual processes with business process automation

- Use Process Street to record and maintain your standard operating procedures

Process Street is a flexible workflow automation tool you can use to gain a competitive advantage by automating almost any process you can imagine.

Need to build a central repository of your manufacturing processes? Process Street’s Inbox and Template Overview features have you covered.

Want to implement quality management standards like ISO 9000 with a lean, agile workflow management software? Yep, you can do that with Process Street.

You can even use Process Street to innovate and improve your manufacturing procedures by using these ready-made SWOT and FMEA analysis templates.

Check out this extensive intro webinar for tips on getting started and inspiration on how you might use Process Street to gain a competitive advantage in your business.

Oh, and don’t forget to sign up for a free trial. It’ll take you about two minutes.

Value chain analysis process

Porter’s generic strategies above are just one element of the value chain model. They are a starting point, and are intended to be seen as general guidelines for understanding how to approach gaining a competitive advantage (hence the name).

But, we can look at Porter’s work and identify a useful and simple process for performing a general value chain analysis:

- Step 1: Determine primary and support activities

- Step 2: Analyze the cost-value relationship of activities

- Step 3: Identify opportunities to gain competitive advantage

Value chain analysis should be led by decision-makers of your organization to align central strategies with value chain findings, but it’s also worth bringing in key individuals from different departments to provide valuable insight from ground-level.

These people are the process owners, and will be able to provide you with invaluable insight into the inner workings of your business processes.

Step 1: Determine primary and support activities

Make a list of all the processes in your business. Then, categorize them as either primary or support activities, based on the information and definitions above.

The primary and support activities are the value chain. You must start by identifying these crucial processes in the development of your product or service, from raw resources to finished product.

Step 2: Analyze the cost-value relationship of business processes

For each of your processes, brainstorm the cost and the value of each process in terms of inputs and outputs.

For each process, question whether or not it supports the type of competitive advantage you’re trying to achieve (cost leadership, differentiation, or focus, from above).

Questions to ask: How labor-intensive is each process? What can be outsourced? Can X raw material be sourced cheaper?

Areas for improvement will be identified by examining the cost-effectiveness of each business process, in terms of the value output.

Step 3: Identify opportunities to gain competitive advantage

After the analysis is complete, bring together top-level management and relevant stakeholders to decide which areas for improvement to prioritize.

You may want to use the results to inform further analysis, for example you could perform a Failure Mode and Effects Analysis using a checklist template like this to identify possible improvements:

Similarly, you could use a SWOT analysis template for similar process improvement opportunities:

In any case, after you finish with the value chain analysis, primary stakeholders will be able to see a clear overview of areas to improve upon. Remember, the goal is to figure out how to gain a competitive advantage.

Start with low-effort, high-impact changes. If you’re struggling to organize your to-do list of process improvements, consider using a prioritization matrix to figure out the best choice. We have a template for that, too;

With the value chain analysis, you’ll have a clear idea of how to tweak and improve your business processes to provide the most value at the lowest cost possible, ultimately netting you a solid competitive advantage.

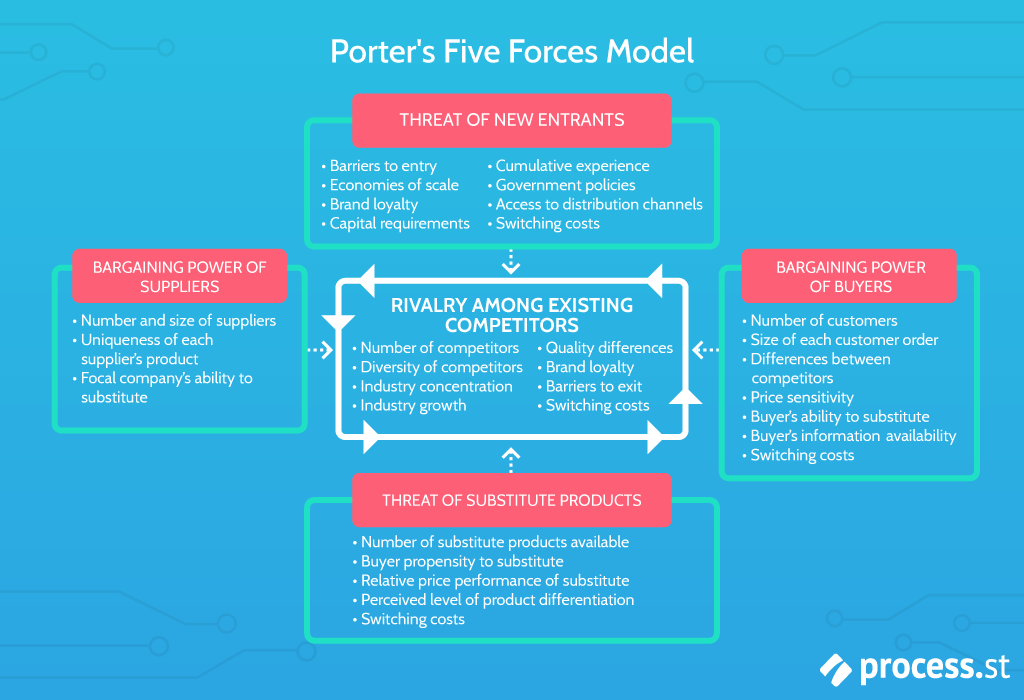

Extended reading: Porter’s Five Forces

Porter’s Five Forces model is a tool you can use to assess how competitive a particular industry is. It is another one of Michael Porter’s tools for business analysis.

Porter’s Five Forces model is a tool you can use to assess how competitive a particular industry is. It is another one of Michael Porter’s tools for business analysis.

While it’s true that Porter’s Five Forces model typically targets a different area to the value chain approach, both share the common goal of improving a company’s competitive advantage.

Porter’s Five Forces is perhaps better suited to analyzing an entire industry, whereas the value chain tool is more focused on gaining insight into the activities of a particular business working within that industry.

Clearly, they can be used in tandem to bolster the likelihood of a successful competitive advantage. Understanding the Five Forces model is immediately useful in making sure that the value chain analysis hasn’t missed any glaringly obvious points of improvement.

If you’re interested in reading more about Porter’s Five Forces model, you should check out this article written by my colleague: What is Porter’s Five Forces Model? Competitive Position Analysis Explained

And, if you’re hungry for more process optimization resources, we have a wealth of information for you!

Just take a look at the posts below:

- Production Systems: Why Tesla’s Gigafactory is Musk’s Most Ambitious Project Yet

- SWOT Analysis Template: What, How, & Why? (Free Template)

- Prioritization Matrix 101: What, How & Why? (Free Template)

- Agile ISO: A Holistic Business Process Management Framework

- Warren Buffet’s Investment Checklist – The Secret to His Success?

- What is TAM SAM SOM? How to Calculate and Use It in Your Business

- How 4 Top Startups are Reinventing Organizational Structure

Can you boast a competitive advantage in your business? How did you achieve that, and would you consider using the value chain model to improve your current position? Leave a comment down below!

Workflows

Workflows Projects

Projects Data Sets

Data Sets Forms

Forms Pages

Pages Automations

Automations Analytics

Analytics Apps

Apps Integrations

Integrations

Property management

Property management

Human resources

Human resources

Customer management

Customer management

Information technology

Information technology

Oliver Peterson

Oliver Peterson is a content writer for Process Street with an interest in systems and processes, attempting to use them as tools for taking apart problems and gaining insight into building robust, lasting solutions.