If you’re chronically ill, pain medication will help but not solve the issue. Just like if you’re experiencing abnormally high customer churn, the last thing you want is to spend all your time firefighting.

You need to find the cause.

That’s exactly why root cause analysis is a vital process. It helps you to understand the causal focus and underlying issues behind your biggest business problems.

For example, Eastman Chemical‘s customer complaint numbers were cut in half after conducting a logic tree root cause analysis to pinpoint their deeper issues. Clipper Windpower saved $1 million in lost revenue by identifying the underlying causes of their turbine malfunction.

In this Process Street article, we have a root cause analysis template for you to follow. Our aim is to give you a comprehensive overview of the root cause analysis process, from a simple introduction and break down of the key principles to when and why you’d want to perform a root cause analysis.

We’ll be covering:

- Root cause analysis template

- What is root cause analysis (RCA)?

- Why conduct a root cause analysis?

- Key principles of root cause analysis

- How to conduct a root cause analysis that actually works

- Root cause analysis tips

- Using Process Street to conduct a root cause analysis

Let’s take a quick look at the root cause analysis template.

Root cause analysis template

If you want to use the template above, just sign up for a free trial (it takes about two minutes).

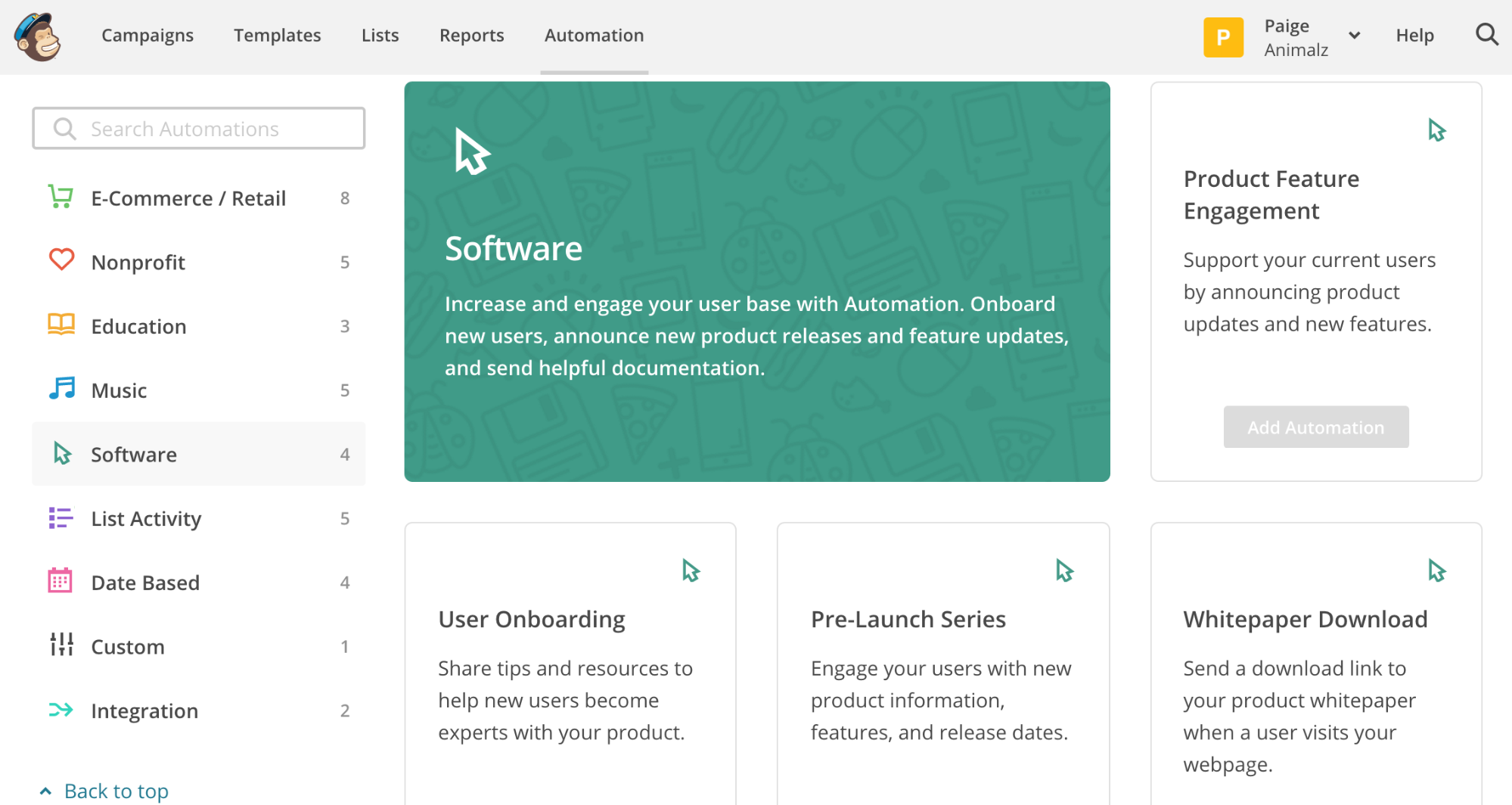

This Root Cause Analysis Template was made in Process Street. Process Street is a BPM software that allows you to build, maintain, and optimize your business processes. This process was built completely from scratch and uses Process Street features like:

- Role assignments (for seamless collaboration)

- Approvals (to ensure work is done properly and to the highest quality)

- Stop tasks (to enforce process adherence and reduce error)

Here are some other checklists you may be interested in:

- SWOT Analysis Template

- FMEA Template: Failure Mode and Effects Analysis

- Gap Analysis Template

- Prioritization Matrix Checklist Template

So, back to root cause analysis. In simple terms, what exactly is a root cause analysis?

What is root cause analysis (RCA)?

Root cause analysis (RCA) involves pinpointing the root cause of problems to be able to find the best solutions for them. This methodology highlights the importance of taking preventative and corrective measures, as opposed to just treating the symptoms of problems, as so often is the case.

There are various techniques and principles that can be used to perform root cause analysis to help identify underlying issues. RCA attempts to look past what may seem like the obvious cause and effect, and help find exactly where systems failed to begin with.

Why conduct a root cause analysis?

There are generally three goals when conducting a root cause analysis:

- To pinpoint the root cause of a problem

- To gain a full understanding of how to correct the underlying problems

- To implement what was learned to fix the current problem and to prevent it from happening again in the future

The third goal is arguably the most important, because what good is conducting an analysis if nothing is done with the information?

RCA can be used to optimize company processes and set preventative measures to mitigate any future issues. For example, instead of constantly responding to support tickets, you could ask why your customers are making those requests in the first place. Could the onboarding process be improved? Is the product experience confusing? Are you properly educating your customers on how to use your product?

Though treating the symptoms of deeper issues may seem quick and effective at the time, it only leads to future repetition of the same problems. In the long run, you’d save significantly more time and effort by addressing the root cause straight on.

Key principles of root cause analysis

Some of the key principles to keep in mind when conducting a RCA include:

- Make efforts to look past the symptoms to identify the root cause

- Know that there may be more than one root cause

- Don’t focus on who was responsible, focus on why it happened

- Always look for definitive evidence to support the hypothesized root cause

- Gather enough information to devise a plan of action and correct the issues

- Decide how best to prevent similar problems from occurring in the future

These key principles highlight the value of looking at the bigger picture, building context, and taking direct action when addressing systemic issues. Following these principles will ensure your analysis is high quality and offers valuable, actionable results.

How to conduct a root cause analysis that actually works

So, you’ve decided to conduct a root cause analysis, but don’t know where to begin. There are many techniques and approaches that you can use for this, so we’ll cover some of the most popular methods out there.

5 Whys

The 5 Whys method is one of the most popular techniques used when conducting a root cause analysis. In principle, this method is very straightforward. It entails asking ‘why’ over and over, until the core issues are exposed. On average, it takes five whys until you get to your root cause, but the range varies from company to company and problem to problem.

Stephen Spear has a great example of the 5 Whys process in his book, The High-Velocity Edge: How Market Leaders Leverage Operational Excellence to Beat the Competition:

The scenario is: A vehicle will not start.

First why?

Answer: The vehicle’s battery is dead.

Second why?

Answer: The alternator isn’t working.

Third why?

Answer: The alternator belt is broken.

Fourth why?

Answer: The alternator belt was beyond its service life and wasn’t replaced.

Fifth why?

Answer: The vehicle hasn’t been maintained according to the recommended service schedule. (Root cause)

In this example we can see that, after these five questions, the root cause of the vehicle’s dead battery is a lack of maintenance. So, to address this issue and mitigate any future problems, all vehicles need to be serviced properly according to their schedules.

The 5 Whys method helps to not jump to conclusions by focusing on digging deeper and deeper until the core answers are revealed. Also, keep in mind, your final answer should lead to actionable conclusions.

Here’s a template we built following the 5 Whys method:

Fishbone diagram

A fishbone diagram, also known as an Ishikawa diagram, is another very popular RCA method. It involves creating a visual cause-and-effect map to help pinpoint root causes by asking you to follow various potential paths until you arrive at the correct one. It’s kind of like a visual representation of the 5 Whys method.

You begin with recording the problem in the center of the diagram (the fish spine), and then jotting down several possible causes for the problem, placing them around the main problem in branches (the fish rib bones). The initial branch categories begin as very broad ideas, such as “environment” or “communication”, and then each of those categories branch out further into smaller, more specific categories. For instance, “communication” may branch out into subcategories like “internal communication tools”, “company communication policies,” or “workplace politics.”

It’s basically using a process of elimination, where you dig deeper and deeper into each potential cause until you arrive at the root cause. This method is more efficient if you take the time to carefully choose your initial categories to better focus on the main problems.

Some commonly used categories in a Fishbone diagram include:

- Technology

- Process

- Physical labor

- Employee expectations

- Management

- Product/service

- Maintenance

- Price

- Marketing

- People

- Employee performance

- Environment

- Suppliers

- Employee skills

These are both examples of continuous improvement. We’ve written a lot about continuous improvement at Process Street. If you’re interested in more relevant resources, then check out these articles:

- What Continuous Improvement Is (and How to Use It)

- Kaizen: How to Deploy Continuous Improvement to Rocket Your Success

- How to Use The Deming Cycle for Continuous Quality Improvement

- What is VRIO? The 4-Step Framework for Continuous Business Success

- Agile ISO: How to Combine Compliance with Rapid Process Improvement

- PDCA: How to Eliminate Error in Your Processes and Products

Tips for an effective root cause analysis

1. Ask a lot of questions

The more questions you ask, the more likely you are to identify the root cause. Continue to ask questions even if you think you’ve arrived at the underlying problem. For example, ask questions like, “How can we be sure this is the root cause and not something else? How can we prevent this from happening again in the future?”

Use these questions to help guide you towards a better understanding of your problem.

2. Work together with others

Sometimes it’s easy to miss something even if it’s right under your nose. If you work with a fellow colleague or a team, it will help identify solutions quicker because you have access to a fresh perspective. They can also offer alternative solutions you may not have thought of on your own.

3. Perfect your root cause analysis with practice

When you’re conducting your root cause analysis, don’t just blindly jump in and run through it. It’s important to be aware of the process as you’re moving through it. Consider what could be changed or improved for next time. Doing this means that your RCAs will be more efficient and effective each time.

4. Conduct a root cause analysis for successes as well

Though RCA is typically used to determine the root cause of problems, it can also be used to identify the root cause of successes. This gives you the tools necessary to be able to intentionally repeat these successes in future or adapt them to other areas of your business to make improvements.

Using Process Street to conduct a root cause analysis

There are a few ways you might perform a root cause analysis. Maybe you have an in-person brainstorming session with a good, ol’ fashioned whiteboard, maybe you knock together a Microsoft Word document which you’ll distribute to your team via print or email, or maybe you use a BPM software like Process Street.

You’ve already seen our Root Cause Analysis Template. Maybe you’ve already signed up for a free Process Street account. If you’re not sure what Process Street is about, check out this quick video:

We mentioned that the Root Cause Analysis Template uses role assignments, approvals, and stop tasks: that’s just the tip of the iceberg. Depending on how complex you want to make your process, you can effortlessly edit the template in this article to include even more functionality, like:

- Conditional logic (for dealing with complex and variable outcomes)

- Dynamic due dates (for time sensitive tasks)

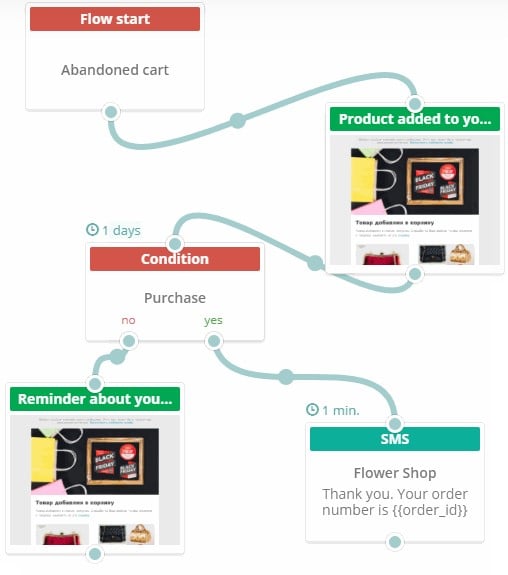

- Automations (to make recurring tasks even more efficient)

Process Street integrates (via Zapier, Webhooks, and API) with 1500+ different apps. So, you can hook up all of your internal processes to the tools you already use on a daily basis. My colleague, Blake, has a great webinar on how to get started (and succeed) with Process Street’s automations:

Check out these related articles for more information on business process management:

- 9 Benefits of Business Process Management (BPM) and Why You’ll Love It

- What is BPM Software? The Best Business Process Management Software (BPMS)

- The Complete Guide to Business Process Management is Here!

- What is Business Process Management? A Really Simple Introduction

- Process Management Explained: How to Combat Poor Processes in Your Business

- Maintenance Management: 6 Steps for Scaled Production and Growth

If you’re wondering about best practices for performing a root cause analysis with Process Street, just drop us a comment below! We’ll be happy to give you tips and help walk you through the process.

Oliver Peterson

Oliver Peterson is a content writer for Process Street with an interest in systems and processes, attempting to use them as tools for taking apart problems and gaining insight into building robust, lasting solutions.