I have a question for you.

What does a Formula 1 racing team, like Ferrari, have in common with a high-flying company, like Apple?

They’re both in highly competitive industries? They’re both focused on improving their performance? They’re both incredibly driven to succeed? They’re both intent on being the best in the world?

Yes, yes, yes, and yes.

In other words, they both strive, in everything they do, to achieve Operational Excellence (Op Ex). However, achieving Operational Excellence is far from easy, and (fortunately for Apple and Ferrari) only 36% of companies manage it.

So, buckle up and join this Process Street post, as we race through the following topics and learn, from the likes of Ferrari, Apple, Disney, and Google, how to become operationally excellent:

- What Operational Excellence is (& what it isn’t)

- The four key creators of Operational Excellence

- 10 ways to achieve Operational Excellence

- The real reasons organizations fail to achieve Operational Excellence

- How to overcome Operational Excellence challenges

Ready to zoom into pole position? ️

What Operational Excellence is (& what it isn’t)

Operational Excellence (Op Ex) is, in simple terms, about being the best. The best in class. The best in your industry. The best in the world.

But, as simple as that sounds, Operational Excellence is an ambiguous concept that a lot of companies strive to achieve, but often fail to understand.

“No executive in the world would turn down Operational Excellence if you handed it to them on a platter even if they don’t exactly know what it is. It just sounds like something awesome” – KaiNexus, What it Takes to Achieve Operational Excellence

For instance, what does being “the best” mean? What does being “the best” look like? Who decides what “the best” is? What makes an organization “the best“?

To understand Operational Excellence and what being “the best” means for companies like yours, let’s bring it back to Ferrari for a second. They’re a great example of an (unofficially) operationally excellent organization.

Being the best for them is all about winning races. It’s all about crushing the competition, standing on the podium, holding the trophy, and spraying the champagne.

They continually work on improving their race strategies, their cars, their drivers, and their teams so they perform better than their competitors.

Their drivers spend hours driving test laps, training in the gym, and memorizing upcoming race tracks and plans so they’re prepared.

Their mechanics spend months designing, re-designing, manufacturing, and testing each part of the car, so they can shave milliseconds off lap times.

Their team principles spend every possible second analyzing previous races and performance data, so they can find the best possible race strategies.

Ferrari has cultivated a culture where people feel empowered to achieve their end goal, which is to:

“Drive change by constantly searching for better ways of doing things” – Mission Winnow, What is Mission Winnow?

As a direct result, they’ve won 231 races since their first race in 1950 (the highest number among all teams throughout F1 history), and are considered the best F1 team of all time.

Achieving Operational Excellence and, therefore, becoming the best, is exactly the same for any other organization.

To become the best, operationally excellent companies like Amazon, Google, and Disney formulate and execute strategies that continually beat their competition.

They’ve each built and maintained positive work cultures that motivate and empower their staff. These cultivated cultures have allowed them to become innovative, customer orientated, and continuously focused on improving their products, services, and processes. As a result, they’ve become the best in the world.

“Operational Excellence is the execution of the business strategy more consistently and reliably than the competition” – Wilson Perumal & Company, A Better Definition of Operational Excellence

We’ll go into detail around how to execute strategies “more reliably and consistently than the competition” later. But, to give you a sneaky preview, you can achieve Operational Excellence by following a framework that is based around a core set of principles.

I’ll be divulging some of these frameworks, all of these principles, and much, much more, later!

Anyway, that’s what Op Ex is. But, because it’s such a hazy concept, to get a full understanding, we should also consider…

What Op Ex is not

Op Ex is not just a tick-box exercise

Achieving Operational Excellence is not about completing a list of tasks or activities. It’s a mindset that you must adopt, develop, and instill within your entire organization.

“Operational excellence is more of a mindset that accepts certain principles and tools to create sustainable improvement within an organization” – Reliable Plant, Operational Excellence: An Overview

Op Ex is not just about reducing costs & increasing productivity

Creating operational efficiencies and increasing productivity levels is part and parcel of running a successful business. That’s a given. But, to achieve Operational Excellence, you need to go a step further. Your focus shouldn’t just be on the bottom line. It should be on creating a culture that enables you to grow, develop, and continuously find new ways to improve your productivity and efficiency levels.

Op Ex is not just for big organizations

Although big boys such as Toyota and Tesla are great examples of companies who achieve Operational Excellence, that doesn’t mean smaller companies can’t and don’t achieve it too.

The concept of Op Ex is built around teams of people working together on problems and opportunities that are aligned with organizational goals. That, as a concept, is versatile and can be applied to a business that has only two people and also a business that has over 2,000 people.

Size doesn’t matter (on this occasion).

Op Ex is not just for manufacturers

As we’ll discover in a second, Op Ex started in manufacturing, but it certainly didn’t stay exclusive to manufacturers. Any company that has operational processes, can benefit from becoming operationally excellent.

We’ll continue to unpick the concept of Operational Excellence as and when we talk about how to achieve it.

First, I want to explain where Operational Excellence came from and how it was developed.

To do this, allow me to introduce you to…

The four key creators of Operational Excellence

Operational Excellence is a huge topic to tackle. Mainly because it consists of several different concepts all rolled into one. Therefore, its origins come from a mixture of methodologies, theories, concepts, and tools, developed and created over centuries by lots of influential people.

But, specifically, it’s the following four people that have played the biggest part in creating the concept and shaping it into what it is today: Adam Smith, Henry Ford, William Deming, and Dr. Shigeo Shingo.

Let’s meet them properly.

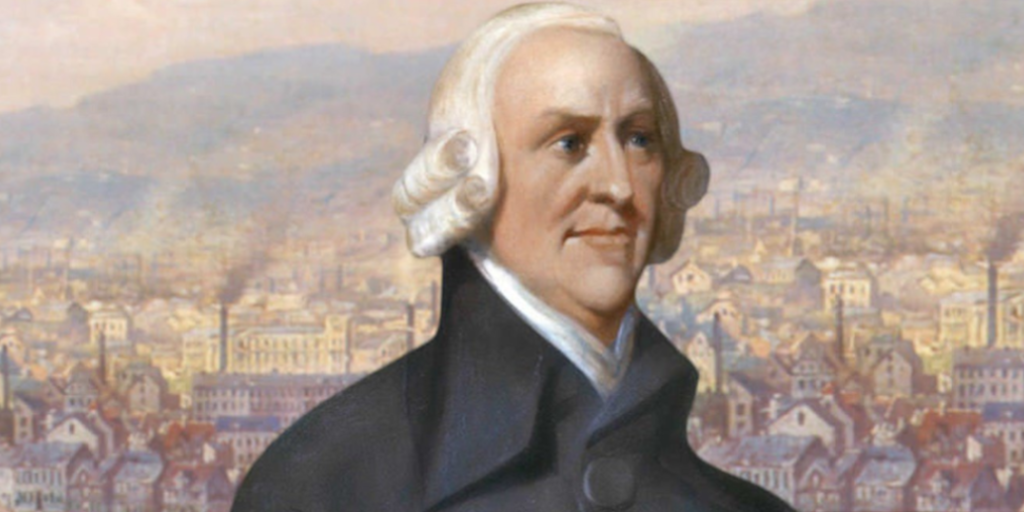

Who is Adam Smith & what part did he play in developing Operational Excellence?

Adam Smith: Economist, philosopher, founder of the ‘division of labor’ principle, and the first to define Operational Excellence as a concept.

In his infamous book: “The Wealth of Nations” he describes a pin factory that had 10 workers. Each worker would work individually, and make one pin per day. Smith suggested, to the factory owner, that rather than working separately to make each pin, the 10 workers should work together. He hypothesized that if he divided the entire pin-making process up into 10 tasks, and if each worker took on one task each, they would end up making way more pins. With nothing to lose, the factory owner agreed to try it.

Boy was he glad he did!

This small change in operations meant that the factory started to produce over 48,000 pins a day, as opposed to ten.

It revolutionized the way businesses worked and taught companies to continuously look for ways to improve their products, services, and processes.

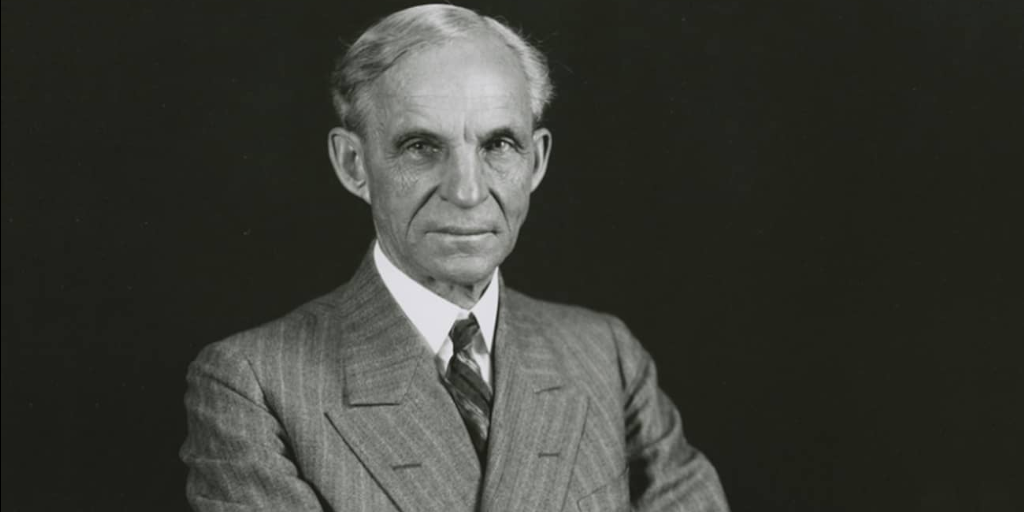

Who is Henry Ford & what part did he play in developing Operational Excellence?

Henry Ford: Founder of Ford cars, creator of mass production, and manufacturer of the first affordable car.

This guy doesn’t need much of an introduction, but what part did he play in the development of Operational Excellence?

Ford was entirely focused on making the best product possible. He continuously pursued methods that eliminated waste and helped employees to work more efficiently. His efforts led to the creation of the first assembly line and started the revolution of the entire manufacturing industry.

His unwavering dedication to always provide the best, paved the way for organizations to become operationally excellent.

“He drove himself – and his employees – to correct operational inefficiencies while also creating better products” – Six Sigma Daily, Henry Ford and the Roots of Lean Manufacturing

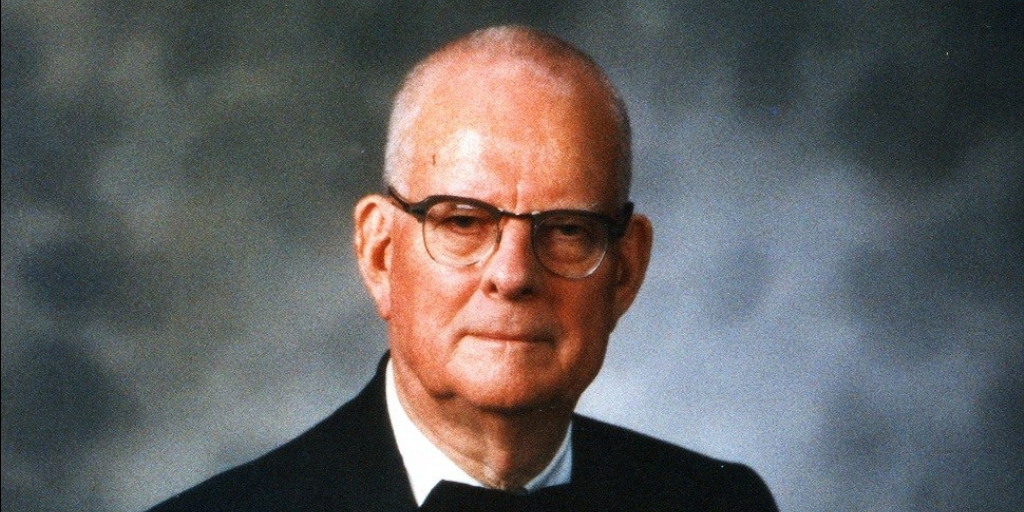

Who is William Deming & what part did he play in developing Operational Excellence?

Next up, we have William Deming. If you’ve read my previous post on Total Quality Management (TQM) you’ll be familiar with this man. A statistician and business consultant, Deming’s TQM methodology helped Japan recover after the Second World War and formed a foundation for Operational Excellence. TQM is based on the idea that to continuously improve quality, you have to create an inclusive culture, which encourages every employee, from the top to the bottom, to look for improvements in themselves, their work, and the organization as a whole.

“His philosophy is one of cooperation and continual improvement; it avoids blame and redefines mistakes as opportunities for improvement” – British Library, W Edwards Deming

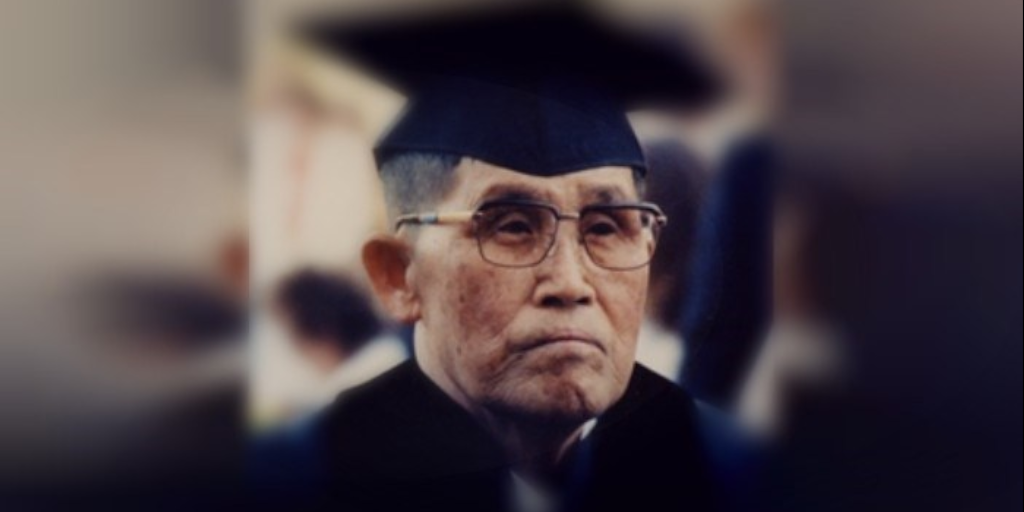

Who is Dr. Shigeo Shingo & what part did he play in developing Operational Excellence?

Many people claim that Dr. Shingo is the real “father of Operational Excellence“. Having written 18 books on the subject, worked for years with Toyota executives to apply Op Ex concepts to real-life situations, and developed 10 Op Ex principles as a result of his work, I can see why.

We’ll re-visit Dr. Shingo, the father of Operational Excellence, in a minute.

Together, over the course of a few hundered years, these four influential men (and a few other influential characters) introduced and developed the concept of Operational Excellence.

Now we’ve discussed what Op Ex is, what it isn’t, and where it comes from, I think we’re ready to find out how to achieve it.

10 ways to achieve Operational Excellence

Remember Dr. Shingo and his 10 Op Ex principles from earlier? Well, this is where we find out what these principles are and how they will help you achieve Operational Excellence.

Top tip: To achieve Operational Excellence, each of the below principles needs to be ingrained into everyday activities. That way, they become part of a culture that encourages every employee to continuously look for improvements in everything they do.

Operational Excellence principle #1. Respect every individual

How do you feel when someone asks for your opinion about something at work?

You feel respected, don’t you? You feel empowered, motivated, and keen to go above and beyond for that person.

If you start asking your employees for their opinions and involving them in improvements and changes within your organization, it will make them feel respected, engaged, and motivated to do more. You’ll begin to build a culture where people naturally want to go above and beyond to support your organization in reaching its goals.

Disney is exceptional at this, and as a result, is consistently at the top of the list when it comes to companies that achieve Operational Excellence.

Despite its apparently low salaries and tight management supervision, Disney employees are known for being engaged, motivated, and willing to go the extra mile in their jobs.

Why?

Because Disney makes a point of treating its employees like customers. They ask for their opinions, they encourage feedback, and they respect each and every staff member. In return, employees feel happy, empowered, invested, and like they’re a true part of the company.

As Bruce Jones, Senior Programming Director, Disney Institute says:

“The more empowered employees feel, the more engaged they tend to be in the technical aspects of their jobs as well as in the quality of service they provide to customers” – Harvard Business Review, How Disney Empowers Its Employees to Deliver Exceptional Customer Service

Operational Excellence principle #2. Lead with humility

The biggest improvements happen when people recognize their shortcomings and look for better solutions. Admitting mistakes, listening to others, and being receptive to suggestions is how you lead with humility.

Leave your ego at the door and encourage your workforce to do the same.

Operational Excellence principle #3. Seek perfection

“Noone’s perfect.” “Perfection is impossible.” “Perfect is an illusion.” “Perfectionism is a failed strategy to avoid criticism.” Blah, blah, blah, blah, blah.

Hundreds of people hate-on perfectionism. Of course it’s unattainable. Of course no one, or nothing, is ever truly perfect, but if we don’t strive for perfection, then what’s the point?

To help me explain this principle, let’s revisit Ferrari once again. They are constantly striving for something called ‘pit stop perfection’.

Formula 1 cars can travel up to 370 km/h during a race. They need their tires changed, engines checked, and fuel added throughout the race if they want to maintain this speed and secure their place on the podium.

This is why pit stops play a crucial part in every race and why Formula 1 teams, like Ferrari, continuously strive for pit stop perfection.

To reach pit stop perfection, the car must arrive into the pitstop, the tires must be changed, the engine checked, fuel added, and it must get out, back onto the track, in under 2 seconds.

“It [should] take less time to complete an F1 pit stop than it does to read this sentence” – AMG Petronas Formula One Team, Insight: Chasing Pit Stop Perfection

The 20 mechanics, who make up the Ferrari pit stop team, work incredibly hard to try and hit that 2-second goal, every time a car comes in.

They complete at least 60 practice pit stops each week. They regularly swap roles to make sure they’re able to pick up someone else’s role in an emergency, and they plan for every possible pit stop scenario.

They are incredibly driven to achieve ‘perfection’. From adjusting the positions of crew members to tweaking the design of the wheel nut; everything they do is centered around shaving mere nanoseconds off their pit stop time.

Watch how they do it, it’s incredible:

This drive for perfection (excuse the pun!), as we discussed earlier, is why they remain the best Formula 1 team in the world (at the time of writing this post).

Operational Excellence principle #4. Embrace scientific thinking

Innovation comes from experimentation. If you show you’re willing to try new concepts, push boundaries, and explore ideas you’ll create a culture that encourages your workforce to do the same.

Apple is widely considered as the #1 most innovative company in the world.

“The only things more impressive than Apple’s financial numbers are the products that generated them” – Robert Dafian, Fast Company, Why Apple is the Most Innovative Company

As a company, they are unbelievably focused on making products that give people the ability to do things they couldn’t do before.

This focus on innovation was installed into the company culture by the late Steve Jobs, when the company started in 1976, and has been carefully nurtured by the current CEO Tim Cook, ever since.

“Apple’s commitment to innovation is cultural, not process-driven” – Innovarsity, Apple’s Systemic Approach To Innovation

In this vibrant, product-oriented culture, rapid innovation is at the center of everything they do.

They have an effective innovation system, designed to harness creativity and spark new ideas, discussions, and activity. Their creative staff are regularly pulled together and encouraged to express their thoughts, remain open-minded, and collaborate with each other on new possibilities and opportunities. They also motivate employees with incentive and reward programs that recognize innovation.

As a result, they remain the #1 most innovative company in the world (at the time of writing this post).

Operational Excellence principle #5. Focus on the process

“Focus on the process” is one of Process Street’s core values. It’s part of our organizational culture and ingrained into everything we do.

But, aside from the fact we’re a business process management platform, why do we place so much value on processes?

Because processes are like bones; without them, you can’t survive. They provide the structure, strength, and support that’s needed for growth and development (read this to find out more about why processes are crucial for businesses).

When mistakes happen, or something goes wrong, it’s all too easy to blame it on incompetent, unwilling, or lazy staff. But, most of the time, the problem will be related to a failed operation, not the person doing the work.

By focusing on creating processes for your organization to follow, you’ll find you’re able to identify the root cause of operational problems quicker, and sometimes even get there before the problem occurs.

Operational Excellence principle #6. Ensure quality at the source

“Excellence can only be attained when every element of work is performed correctly the first time” – KaiNexus, What it Takes to Achieve Operational Excellence

Continuing on with the theme of processes: Processes are only effective if they’re documented for everyone to see, and optimized so that they help people perform their tasks right, the first time, every time.

Also like bones, processes can only provide structure, strength, and support if they’re nurtured and looked after.

Processes that are left to gather dust, never reviewed, changed, updated, or improved can break a business. They don’t support growth, they provide little structure, and they allow operational inefficiencies and mistakes to creep in.

“Even the smartest and most engaged employees cannot consistently produce high-quality results with poor processes” – KaiNexus, What it Takes to Achieve Operational Excellence

To learn how to create, document, and improve your processes, I highly recommend you read this post, and grab this free template (sign up for a free trial if you’re not yet familiar with Process Street):

Click here to access the Process for Optimizing a Process!

Operational Excellence principle #7. Flow and pull value

“Creating flow and pull systems help deliver higher value to the customers. The benefits include: achieving faster, more reliable delivery, understanding capacity, identifying problems, and reducing waste” – Catalysis, Why Create Flow & Pull Value?

To achieve Operational Excellence, companies need to increase their flow and respond to their pull.

“Increase their flow and respond to their pull…”

What the…What does that even mean?

Let me explain.

- Flow is all about how you move your product through the production process. It’s the way you create, make, and get your product out the door, to your customers

- Pull is all about responding to customer demand, or ‘customer pull’

So, to ‘increase your flow’ you need to regularly examine, identify, and remove anything from your operational processes that does not add value. Increasing your flow will eradicate bottlenecks, inefficiencies, unnecessary steps, and give you a greater understanding of your operational capacity. This will allow your production processes to flow more efficiently and reliably.

To ‘respond to pull’ you need to make your products in-line with real-time customer demand. Like chefs do in (nicer) restaurants; they’ll only cook a steak when an order for it comes in. Responding to the customer pull will reduce speculation and waste, which are common bi-products of forecast-based, ‘push methods’.

“Value for customers is maximized when it is created in response to real demand in a continuous and uninterrupted flow” – Catalysis, Why Create Flow & Pull Value?

Operational Excellence principle #8. Think systemically

This one is also linked to processes. To ‘think systemically‘ means to think about the system and the interactions and relationships within that system, as a whole. It means thinking about how the individual processes within your business can work together to help you achieve your main objectives.

Operationally excellent organizations think systemically. They recognize that all processes are connected. They know that if they understand the relationships between each process, they can make more effective decisions and better improvements.

Below is a great little analogy, taken from the “father of systemic thinking”, Prof. Russell Ackoff, that explains systemic thinking perfectly:

Imagine you asked a group of engineers to gather together every model of car that’s ever been produced, into one location.

Imagine you then asked these engineers to test each model and determine which car has the best brakes, which car has the best steering, which car has the best engine, which car has the best frame, and which car has the best suspension.

Then, imagine asking them to take the best parts from each model and put them together to make the best car in the world.

What would you end up with?

Nothing.

You don’t even have the remnants of a car, because nothing fits! All the parts have been made separately, they’re all different sizes, and they don’t work together.

If each department within your organization worked in a silo, to create, improve, and optimize their own processes to create efficiencies within their own teams, although that would be great for each individual department, it wouldn’t be great for the organization. Each department would struggle to work with another because their processes wouldn’t link up. They’d be working in a different way, towards different objectives, and it would be chaos.

Operational Excellence principle #9. Create constancy of purpose

This principle is all about making sure that you, and all your staff, know why the organization exists, where it’s going, and how it plans to get there.

If everyone has a clear idea about what the plans are and which direction the company is heading in, everyone can align their activities to fit in with this. They can innovate, adapt, and take risks with greater confidence.

This is one of Shingo’s principles that has been heavily influenced by Deming’s work and can be traced back to his book: “Out of the Crisis”.

“If there isn’t a shared understanding of what principles are supposed to drive decisions, chaos will result” – The Deming Institute, Create Constancy of Purpose

Operational Excellence principle #10. Create value for the customer

Creating customer value is an obvious, but critical, objective that you must achieve if you want to survive as a business, let alone achieve Operational Excellence.

When I think of companies that create value for customers, I immediately think of Google.

Perhaps not an obvious choice, but hear me out.

We’re all customers of Google (apart from the 1.18% who still use Bing and my Grandma, who refuses to go near a computer).

Although we might not all pay for its advertising spaces, 94% of us use Googles services to find what we’re looking for on the vast worldwide web.

So why do we use the Google search engine and not the engines of Bing, Yahoo, or Ecosia?

Because Google delivers value to us, as its customers.

We are at the center of its world. It goes above and beyond “to organize the world’s information and make it universally accessible and useful” for us. It’s commitment to understanding our search intent and finding better ways to deliver the most accurate and relevant websites that match our queries, have allowed Google to stand out from the competition and become operationally excellent.

“We know that people rely on us, so our commitment will never waver” – Google, Our Approach to Search

So, looking at Dr. Shingo’s 10 principles, achieving Operational Excellence seems simple enough, doesn’t it?

But, when you consider that 36% of companies struggle to achieve it, it can’t be that easy, can it?

Well, truth be told, Op Ex has become renowned not only for its success in organizations, but also for its catastrophic failures.

Let’s look at why.

The real reasons organizations fail to achieve Operational Excellence

Research shows that over two-thirds of Op Ex programs fail. So, where are organizations going wrong? Why can’t they achieve Operational Excellence? What challenges are they facing?

To answer these questions, below, are the three biggest challenges that organizations face on their journey to becoming operationally excellent.

Operational excellence challenge #1: Changing the culture

A massive 53% of organizations say that changing the company culture is their biggest obstacle when trying to achieve Operational Excellence.

“Many companies recognize the need to shift culture but then complain about the difficulty of changing it” BPM institute, Four of the Top Reasons for Operational Excellence Failure

Changing the mindset and behaviors of an entire corporation is hugely complicated, difficult, and time-consuming. It’s changing the way people think, believe, act, and feel. Unengaged employees, change fatigue, and too many priorities are three big factors that make changing culture undeniably tough.

Operational excellence challenge #2: Maintaining Operational Excellence

The next biggest challenge organizations face when striving for Operational Excellence is sustaining their Operational Excellence improvements. While many manage to successfully implement improvements, 36% don’t have a plan for sustaining them and therefore struggle to keep them in place.

Operational excellence failure #3: Transforming the entire company

When organizations start their journey to becoming operationally excellent, they often need to rethink their entire operation, end-to-end. To reap productivity benefits across the entire value chain, they find they need to work in different ways and bring in new, advanced technologies. This involves drastic change, which is problematic and challenging for over 30% of organizations.

Now we know what the top three biggest challenges are, I guess the next question is…

How to overcome Operational Excellence challenges

The challenges that organizations face when striving to become operationally excellent are big, but they are not impossible to overcome.

After all, 44% of organizations are successfully running, and sustaining, effective Operational Excellence programs, which proves it can be done.

But how?

It’s all well and good having Dr. Shingo’s set of principles in front of you, but how do you make sure you and the rest of your company follow them? And how do they help with overcoming obstacles like changing your culture, sustaining your improvements, and going through an end-to-end business transformation?

Shingo’s principles are great as they keep you focused and heading in the right direction. But what you need, alongside these principles, is a set of frameworks or methodologies. Something that will provide a structure for you to follow, support the changes you have implemented, and help you to continuously improve.

3 frameworks to help you follow Shingo’s 10 principles

As we discussed at the beginning, Operational Excellence is about becoming the best. It’s about executing better business strategies than your competitors. It’s about cultivating a culture that focuses on creating value and continuously improving.

Using frameworks, like the ones below, won’t guarantee your success, but they will help you to transform your organization, continuously improve it, and support you on your Operational Excellence journey.

Root cause analysis framework

This framework can be used to pinpoint the underlying causes of recurring problems within your organization. If problems aren’t resolved, you can guarantee that they will a) always come back and b) always come back bigger. To resolve a problem, you need to identify the root cause of it. Which is where this framework helps. Root cause analysis frameworks will help you to identify the root cause of the problems within your organization, and create a plan to fix them.

This will ensure your operations run smoothly, and you’re continuously improving.

Check out the below Process Street Root Cause Analysis template to help you identify your problems and your root causes.

Click here to access the Root Cause Analysis Template!

Hoshin Kanri framework

This framework is a strategic planning process, used by many organizations to implement new goals and policies. The Hoshin Kanri framework will help you with two key tasks:

1. It will help you to align everyone within the organization to your business objectives

2. It will identify the root causes behind problems, and show you how to improve

Grab the template below to get a feel for how it can help you:

Click here to access the Hoshin Planning Process Checklist!

DMAIC framework

This five-step method is another framework that will allow you to identify the root cause of problems and find ways to continuously improve. DMAIC stands for:

- Define: Define the problem

- Measure: Quantify the problem

- Analyze: Identify the cause of the problem

- Improve: Solve the root cause and verify improvement

- Control: Maintain the gains and pursue perfection

But see it for yourself by grabbing the below template:

Click here to access the DMAIC Improvement Project Tollgate Checklist!

The above suggestions are only three possible Op Ex frameworks that you could consider using, but there are hundreds. At the end of this post, I’ll add a list of resources that you can delve into, to find out more.

Before I do that, you may have noticed a few Process Street templates throughout this post?

You may, therefore, be wondering how to use them, how to access them, what Process Street is, and what it has to do with Operational Excellence?

If so, read this next bit and all will become clear.

What is Process Street?

Process Street is superpowered checklists.

It’s a business process management (BPM) platform that can support you on your journey to becoming operationally excellent, by allowing you to document, follow, and continuously improve processes for all your recurring operational tasks.

Watch this video, or read this article, before I tell you more.

As you can see, Process Street enables you to build robust templates that encourage employees to think systemically, focus on the process, and minimize human error. You can include your workforce in decisions by assigning them tasks. You can identify and remove bottlenecks from operational workflows by sending work for approval automatically, and you can easily track progress and activity through the checklist dashboard.

But the real beauty of Process Street lies in its ability to automate workflows and create efficiencies within your everyday operational tasks. For instance, you can connect your operational workflow templates to the platforms you use all the time (like Word, Google Docs, or Outlook), through Zapier, Webhooks, or API integration. This will make the transfer of key information from both platforms reliable, quick, and accurate.

The below webinar explains how automation works with Process Street, better than I do, so go check it out:

Some of the templates I’ve included in this post may need tweaking to fit your organization. Use the below features to customize your templates, or make your own set of Operational Excellence framework templates from scratch:

- Stop tasks

- Dynamic due dates

- Task permissions

- Conditional logic

- Approval tasks ✔️

- Embed widget ️

- Role assignments ♀️

- Webhooks ↩️

- Many, many more 🙂

Whether you choose Process Street to build-out your Operational Excellence templates, or whether you decide to use an alternative method, make sure you choose a platform or tool that:

“Provides a central repository for all opportunities for improvement, allows for cross-functional collaboration, and offers active alerts and notifications to make sure that progress never stalls” – KaiNexus, What it Takes to Achieve Operational Excellence

Excellent Operational Excellence reads

As promised, below are some useful articles that all relate to Operational Excellence. Get stuck in!

- Hoshin Kanri: Gain a Competitive Advantage With This Lean Management Approach (Free Template)

- How to Perform a Root Cause Analysis (Free Template)

- DMAIC: The Complete Guide to Lean Six Sigma in 5 Key Steps

- Workplace Culture: What It Is and How to Make Yours Better (With Examples)

- How to Solve Your Problems With Lean Six Sigma (Free DMAIC Checklist)

- Gemba Walk: How to Strive Forward by Taking a Step Back

- How to Use The Deming Cycle for Continuous Quality Improvement

- Choosing a Lean Software Stack: How to Avoid Multiple Systems Chaos

- What is Muda? The 7 Wastes Every Lean Business Needs to Combat

- Pinch Analysis: Process Improvement Tips From Thermodynamics, Cars, and Cooking

- How to Build a Strong Company Culture for Your Remote Team

- 9 Lean Manufacturing Principles to Kill the Jargon and Get Quality Results

- How to Start a Lean Process for Continuous Company Learning

- Key Takeaways from 5 Excellent Company Culture Examples

- Evolving Processes in Lean Startups

- How to Easily Achieve Effective Employee Communication in Your Team

Before I lower the chequered flag, let’s finish the race with some wise words from an old Ferrari driver; Lewis Hamilton:

“In racing, there are always things you can learn, every single day. There is always space for improvement, and I think that applies to everything in life”

We’d love to hear how you go about achieving Operational Excellence in the comments below. Who knows? You may even get featured in an upcoming article!

Amanda Greenwood

Amanda is a content writer for Process Street. Her main mission in life is to write content that makes business processes fun, interesting, and easy to understand. Her background is in marketing and project management, so she has a wealth of experience to draw from, which adds a touch of reality and a whole heap of depth to the content she writes.