From Operational Chaos

to AI-Powered Precision

Process Management So Simple,

Operational Efficiency Is

Inevitable.

Trusted by top companies to revolutionize workflow management

Easy-to-use, no-code Process Platform

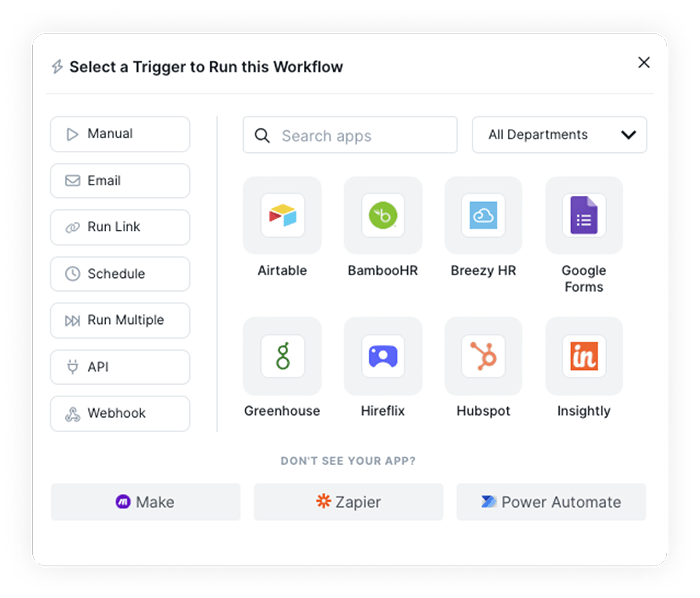

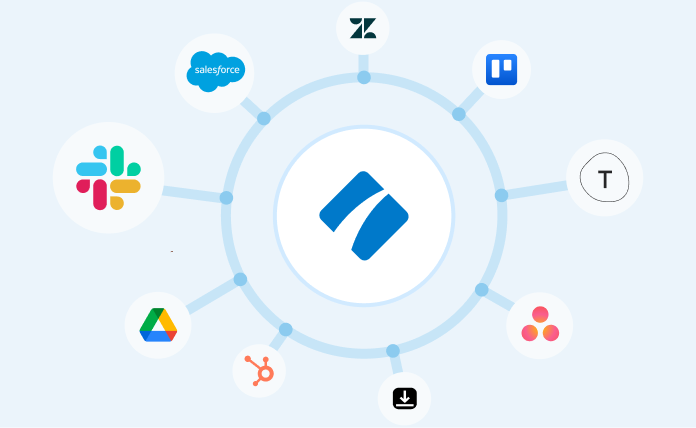

Integrate your tools with Process Street

Workflows, Forms, and Data Sets

to begin leveraging the power of AI

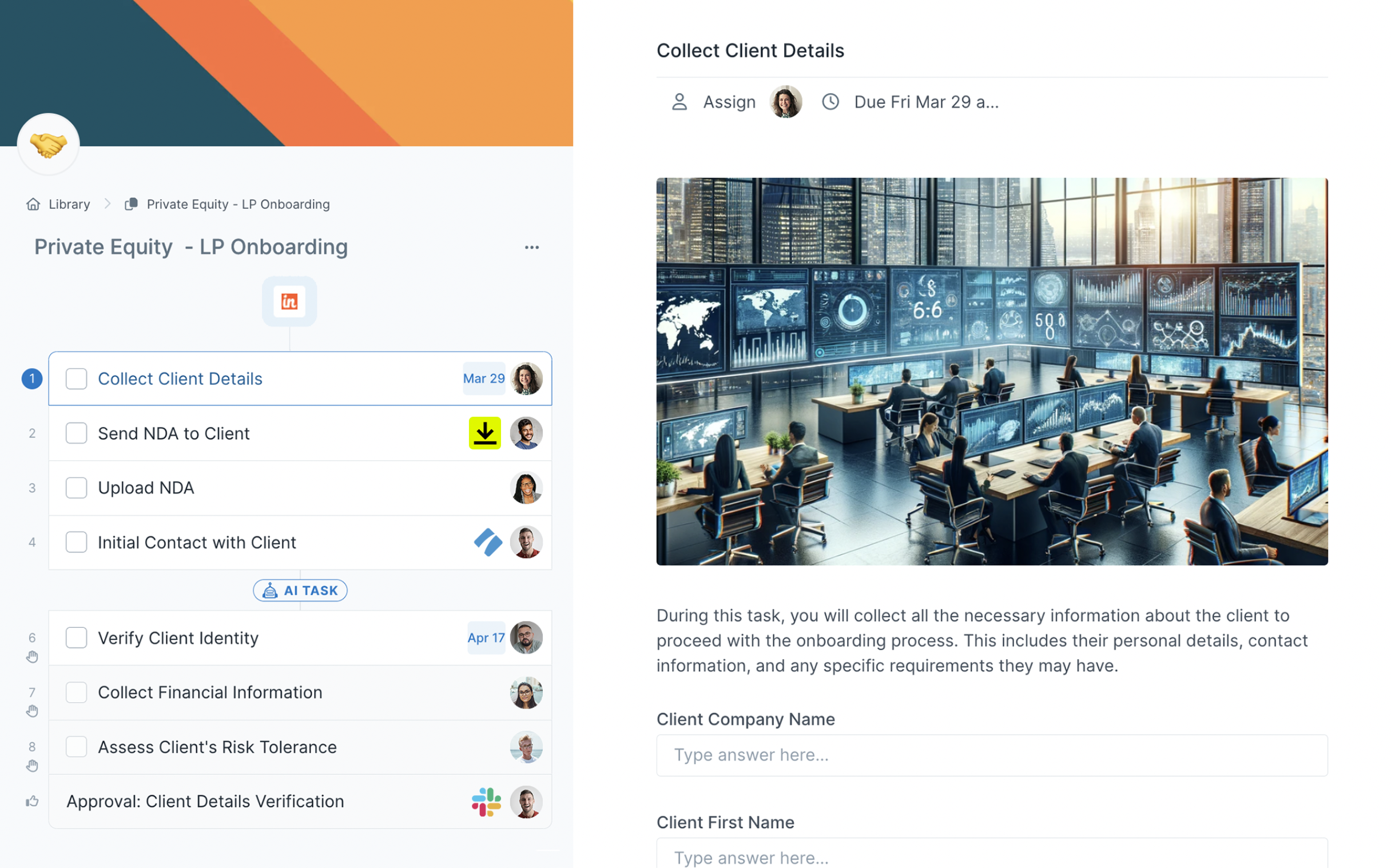

AI-powered workflows

Our intuitive AI-powered workflows enables teams to create and follow step-by-step workflows for various processes, ensuring consistent adherence to procedures and minimizing costly errors across the organization.

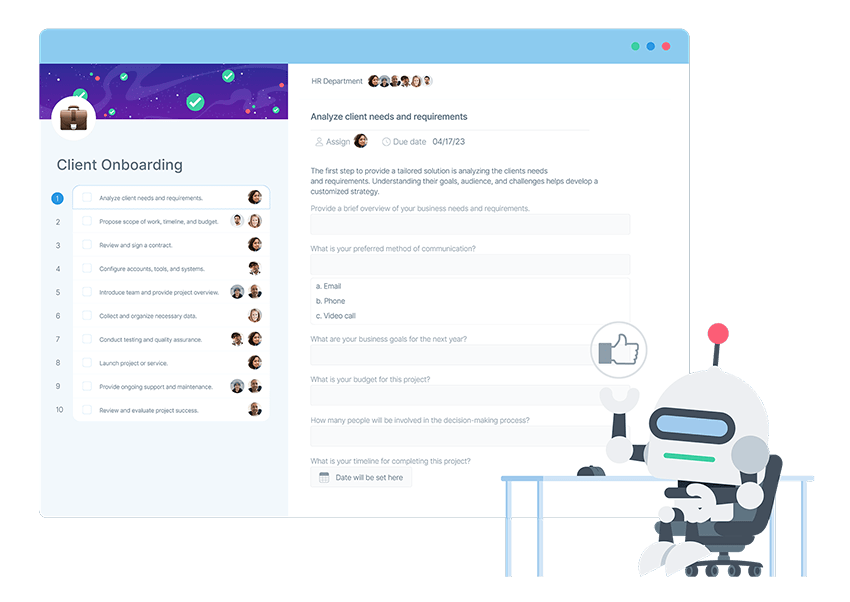

Increase efficiency and productivity... with fewer resources

Automate repetitive tasks using generative AI and built-in integration tools to reduce manual labor and free up valuable time.

Get started

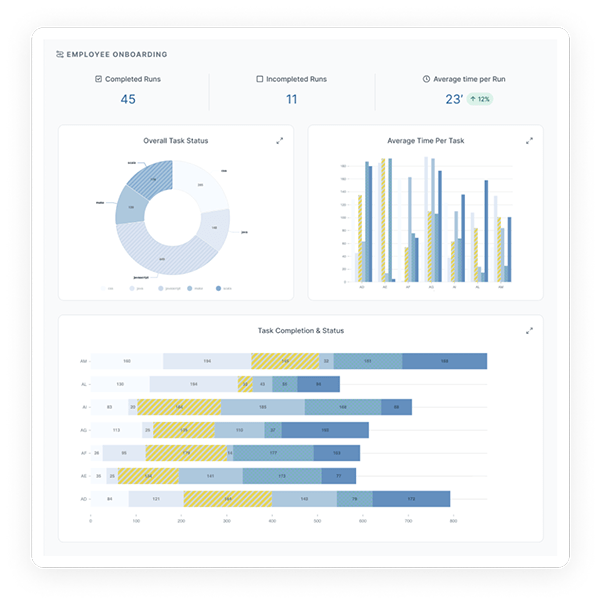

Make data-driven decisions

Process Street offers powerful analytics features that help organizations track key performance indicators (KPIs) and monitor everyone's progress throughout their processes.

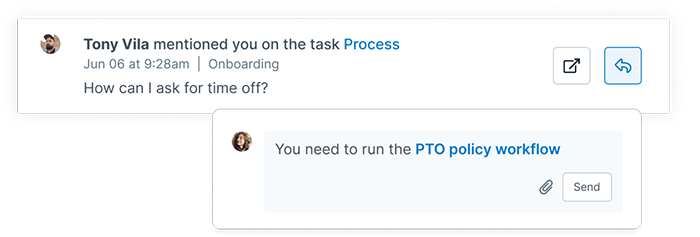

Get startedSimple, efficient knowledge sharing

Eliminates information silos and ensures everyone on the team has access to necessary team knowledge.

Get started

Backed by happy clients

functional team collaboration.”

Get started easily

or join us on a live demo. However you want to get started, we've got you covered!

An industry-leading solution

Always here to help

Get the assistance you need with our professional support team

Workflows

Workflows Forms

Forms Data Sets

Data Sets Pages

Pages Process AI

Process AI Automations

Automations Analytics

Analytics Apps

Apps Integrations

Integrations

Property management

Property management

Human resources

Human resources

Customer management

Customer management

Information technology

Information technology